UV DTF troubleshooting is essential for anyone aiming to maximize the quality, reliability, and longevity of their UV-curable ink workflow, the backbone of modern film-transfer systems that print vibrant graphics on a wide range of fabrics and hard surfaces, and it begins with a deliberate plan to diagnose performance gaps, correct misconfigurations, and prevent recurring defects from eroding print integrity over time, while also ensuring compatibility with evolving standards and new substrate geometries. In practice, successful DTF printing troubleshooting connects printer calibration, color management, curing dynamics, and media handling into a cohesive routine that translates test patterns into repeatable, production-ready results across different inks, substrates, and environmental conditions. When issues crop up—color shifts, ghosting, banding, or adhesion problems—the first moves are to confirm nozzle health with a dedicated check, verify ICC profiles align with the substrate, and measure UV energy delivery at the target distance, because each factor feeds the others and a missed cue here can cascade into noticeable defects in the final transfer. A robust troubleshooting regime also emphasizes proactive maintenance, including scheduled ink agitation and purge routines, regular cleaning of rollers and print heads, and a documented change-log for media compatibility tests so you can trace which substrate or ink batch introduced a drift in output, while also elaborating more on the maintenance plan. Ultimately, adopting a structured, data-driven approach yields fewer wasteful reprints, steadier color reproduction, more durable adhesion, and greater confidence when expanding into new substrates or higher-volume production, turning a reactive repair into a reliable, scalable process.

From a broader perspective, the same goal is to optimize the entire film-to-fabric workflow, treating UV-curable inks, transfer films, and substrates as an integrated system rather than isolated steps. Alternative terms like digital textile printing troubleshooting, UV printing issues, or substrate compatibility testing reflect the same challenges, focusing on prepress accuracy, cure performance, and adhesive reliability rather than symptom-based fixes. By framing the topic in terms of color accuracy, media compatibility, ink handling, and printer maintenance, you align content with semantic relationships that improve discoverability while guiding readers toward actionable steps. This approach supports a learning journey where guidance is organized around root causes, preventive checks, and standardized procedures for calibration, cleaning, and material testing.

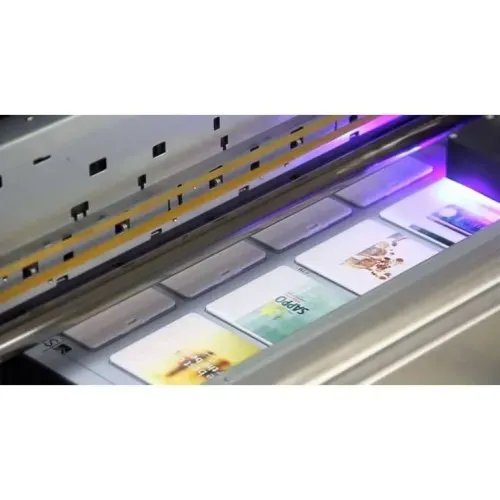

UV DTF Troubleshooting Essentials for Consistent Results

UV DTF troubleshooting is essential for anyone aiming to maximize the quality, reliability, and longevity of a UV DTF printing setup. By aligning hardware, software, and media choices, you create a predictable workflow that reduces waste and speeds turnaround times. This approach leverages elements from DTF printing troubleshooting and UV DTF printing issues to build a robust baseline for every job, whether you’re in a home studio or a production environment.

A systematic troubleshooting mindset helps you isolate factors such as nozzle health, color management, curing, and substrate suitability. Incorporating DTF printer maintenance practices into daily routines ensures that the printer operates within spec, while keeping an eye on ink handling and media compatibility to prevent drift in color or adhesion over time. In other words, UV DTF troubleshooting becomes a proactive discipline rather than a reactive fix.

Diagnosing Color and Banding Issues in UV DTF Printing

Color mismatch, banding, or ghosting are common UV DTF printing issues that stem from a mix of calibration, media handling, and curing. Regular nozzle checks and print-head alignment should be your first steps, followed by verifying ICC data and color profiles for the substrate. This aligns with best practices in DTF printing troubleshooting and helps you distinguish between ink, media, and mechanical causes.

In-depth diagnosis includes confirming proper head height, cleaning any clogged nozzles, and ensuring consistent media transport. When ghosting or banding persists, inspect the color-matching workflow, revisit printer calibration, and validate that the curing process delivers uniform energy across the print area. A careful, layered diagnostic approach reduces the likelihood of repeating the same issue on subsequent jobs.

DTF Printer Maintenance as the Backbone of Print Quality

DTF printer maintenance and best practices form the backbone of reliable, high-quality output. Establishing a routine plan that covers daily nozzle health checks, weekly head cleanings, and periodic roller inspections helps sustain print fidelity and extends equipment life. Regular maintenance is also a key driver of consistent results across different substrates, reinforcing the link between maintenance and media compatibility.

Beyond cleaning, maintenance involves monitoring ink age, storage conditions, and the health of consumables such as belts and seals. Adhering to recommended media and ink recommendations reduces the risk of color drift and adhesion problems. A clean, stable environment—low dust, controlled humidity, and steady temperatures—supports stable printing conditions and better long-term performance.

DTF Ink and Media Compatibility: Selecting Substrates and Inks

The compatibility of DTF ink with media and substrates is central to color fidelity, adhesion, and curing quality. Maintain an approved media list and perform quick trials when introducing new substrates to verify color density, opacity, and transfer durability. This practice dovetails with DTF ink and media compatibility guidelines, helping you avoid color shifts and adhesion failures.

To minimize surprises, perform small-scale tests that include wash tests, cure tests, and adhesion checks before committing to production runs. Track ink age and batch data, since formulation changes or sedimentation can alter drying behavior and color response. A proactive approach to substrate testing is a cornerstone of robust DTF printer maintenance and reliable UV DTF output.

White Ink Issues on DTF: Prevention, Diagnostics, and Remedies

White ink is critical for opacity on dark fabrics and certain substrates, but it frequently causes issues like patchiness or faint areas if the ink is contaminated, poorly agitated, or improperly purged. Addressing white ink issues on DTF requires disciplined maintenance routines, including gentle agitation and thorough purge procedures as part of UV DTF troubleshooting.

Layering order matters as much as nozzle health; in many workflows, white ink is printed first to achieve maximum opacity. Regularly inspect white ink nozzles, perform targeted cleanings for streaks, and ensure the white channel remains primed for continuous production. A structured approach to white ink handling minimizes variability and improves overall transfer quality.

Advanced Techniques for Consistent UV DTF Output and Quality Control

Develop a consistent film-to-transfer workflow that controls variables such as ink age, film type, cure time, and transfer temperature. This aligns with broader DTF printing troubleshooting principles and emphasizes the need for stable curing profiles tailored to the specific ink system. Building a library of test patterns helps you identify problem areas like solid fills, gradients, and white underprints.

Invest in monitoring tools such as a UV radiometer or print quality inspection software to flag anomalies early. Train staff to follow standardized cleaning, calibration, and material handling procedures to minimize human error. A culture of continuous improvement—supported by regular software and firmware updates and a documented knowledge base—drives long-term consistency in UV DTF printing and reduces variability across jobs.

Frequently Asked Questions

What is UV DTF troubleshooting and why is it essential for reliable results in DTF printing troubleshooting?

UV DTF troubleshooting is the structured process of diagnosing and resolving issues in UV DTF printing to improve color accuracy, adhesion, curing, and transfer durability. It starts with confirming printer health (nozzle checks, print head alignment), validating color management (ICC profiles and color data), and verifying proper curing energy. Following a repeatable workflow helps reduce waste, speed production, and maintain consistent transfers across substrates.

How can I address white ink issues on DTF during UV DTF troubleshooting?

White ink issues on DTF often stem from contamination, aging, or improper agitation. Start with thorough purge and circulation, gentle shaking before use, and priming the white channel. Check dedicated white nozzles for clogs, ensure the correct ink order (in some setups white prints first), and run a test to confirm uniform opacity before full production.

What maintenance steps are essential in DTF printer maintenance to prevent UV DTF printing issues?

DTF printer maintenance should include daily nozzle health checks and media path inspection, weekly print-head cleaning and ink agitation, roller and belt inspection, and regular replacement of wear parts. Keep ink storage stable, use recommended media and ink, and maintain a clean environment to minimize dust and static.

How can I fix color mismatch and banding as part of UV DTF troubleshooting, considering DTF ink and media compatibility?

Color mismatch and banding often result from miscalibrated color profiles, clogged nozzles, or media incompatibility. Recalibrate with the latest ICC profiles for the specific media, perform a nozzle purge and head height check, and test a color pattern. Verify media compatibility with the ink set using your media guide, adjust feed speed and print resolution, and clean rollers to prevent feed irregularities.

How important is substrate adhesion in UV DTF troubleshooting, and how does DTF ink and media compatibility affect it?

Adhesion is critical for durability. In UV DTF troubleshooting, ensure substrate cleanliness, proper prepress temperature and pressure, and verify substrate compatibility. Maintain DTF ink and media compatibility by testing adhesion on the target substrate, keeping an approved media list, and performing small adhesion tests before production.

What quick checks can prevent common UV DTF printing issues before production?

Use a simple quick-check workflow: run a nozzle check, test cure with a meter if available, inspect the media path for dust, test a small color block to verify color management, confirm substrate compatibility and ink age, and perform a short test print before full production. Document results to build your troubleshooting knowledge base.

| Topic | Key Points | Common Causes | Practical Fixes |

|---|---|---|---|

| Color mismatch / banding / ghosting | Color calibration, media handling, and curing interplay; banding from clogged nozzles; ghosting from carriage movement. | Clogged/nozzle misalignment; incorrect color profiles; ICC data mismatch; misaligned print heads. | Nozzle check; print-head alignment; verify color profiles/ICC data for media; reprint calibration; adjust feed speed and print resolution. |

| White ink issues | Opacity on dark fabrics; contamination, ageing, improper agitation; nozzle clogging. | Contaminated or aged white ink; improper agitation; clogged white-nozzle channels; improper sequencing. | Purge and circulate white ink; gentle agitation; ensure white channel primed; check layer order; inspect white nozzles; targeted cleanings. |

| Smudging / premature curing | Insufficient curing; overspray; handling too quickly; improper energy delivery. | Inadequate curing; overspray; rapid handling; improper lamp distance/intensity. | Increase curing time/exposure; adjust lamp distance/intensity; slower post-print handling; control overspray/drying parameters. |

| Adhesion failures | Substrate incompatibility; surface contamination; inadequate prepress. | Substrate mismatch; dirty surface; insufficient prepress; wrong temperature/pressure settings. | Confirm substrate compatibility; clean/dry surface; proper prepress temperature/pressure; consider separator/adhesive layer. |

| Print head issues & misalignment | Streaks/ Runs; head clogging or misalignment; cartridge issues. | Clogged nozzles; misalignment; cartridge age or faults. | Nozzle checks; thorough cleaning; recalibrate alignment; verify cartridge age/storage. |

| Substrate & ink compatibility | Substrate-specific reactions; color drift; adhesion/cure variability. | Mismatched media; new substrates; adhesion or cure issues. | Maintain a preferred-media list; adhesion tests; test new substrates; verify substrate compatibility. |

| Diagnosing approach | Systematic checks to isolate issues across workflow. | Multiple potential causes across hardware, software, and media. | Run nozzle checks; inspect media path; verify curing; review color management; test substrates; evaluate post-processing. |

| Preventive techniques & quick-check | Routine checks and documentation to prevent issues. | Lack of maintenance or poor checks. | Daily/weekly/monthly tasks: nozzle checks, media path, lamp checks; firmware updates; maintain knowledge base. |

| Advanced tips for consistency | Holistic workflow; standardized procedures; test patterns; staff training; monitoring tools. | Varied substrate performance; human error; inconsistent lighting or curing. | Develop a test-pattern library; consistent curing profiles; staff training; consider UV radiometer or inspection software. |

Summary

Conclusion: UV DTF troubleshooting is a practical discipline that helps diagnose and fix issues across the entire print workflow, from substrate selection to curing. By understanding common problems such as color mismatch, white ink problems, adhesion failures, curing challenges, and head-related defects, you can implement a structured approach to improve reliability and consistency. Regular maintenance and a robust media-compatibility strategy are essential, ensuring waste is minimized and turnaround times improve. With a proactive troubleshooting workflow, you’ll achieve more consistent transfers, higher customer satisfaction, and a more efficient UV DTF printing process.