In the fast-paced realm of printing technology, **UV DTF** (Ultra Violet Direct to Film) is quickly gaining recognition for its innovative approach to creating vibrant and durable prints. This cutting-edge method harnesses the power of UV inks and combines it with direct-to-film printing techniques, allowing for exceptional print quality on a diverse range of materials, from textiles to plastics and metals. As businesses increasingly shift towards eco-friendly printing solutions, UV DTF stands out by offering sustainable options without compromising on performance. This guide delves into the nuances of UV DTF, uncovering its unique features, applications, and the advantages it brings to industries focused on custom garment printing and beyond. By exploring this revolutionary technology, you’ll discover how UV DTF is transforming the landscape of printing for businesses seeking versatility and efficiency.

Known in various circles as Ultra Violet Direct to Film, UV DTF presents a groundbreaking approach to contemporary textile and product printing. Often referred to as a game-changing printing technology, it merges the benefits of high-performance UV inks with streamlined direct to film processes. This innovative technique is not only paving the way for superior print quality but also aligns with the growing demand for eco-friendly printing methods that benefit both the environment and customers. As industries embrace the flexibility of custom garment printing, UV DTF emerges as a key player, offering limitless possibilities for personalized products. Whether printing on fabric, plastic, or other surfaces, this versatile technology is revolutionizing how businesses approach print design and production.

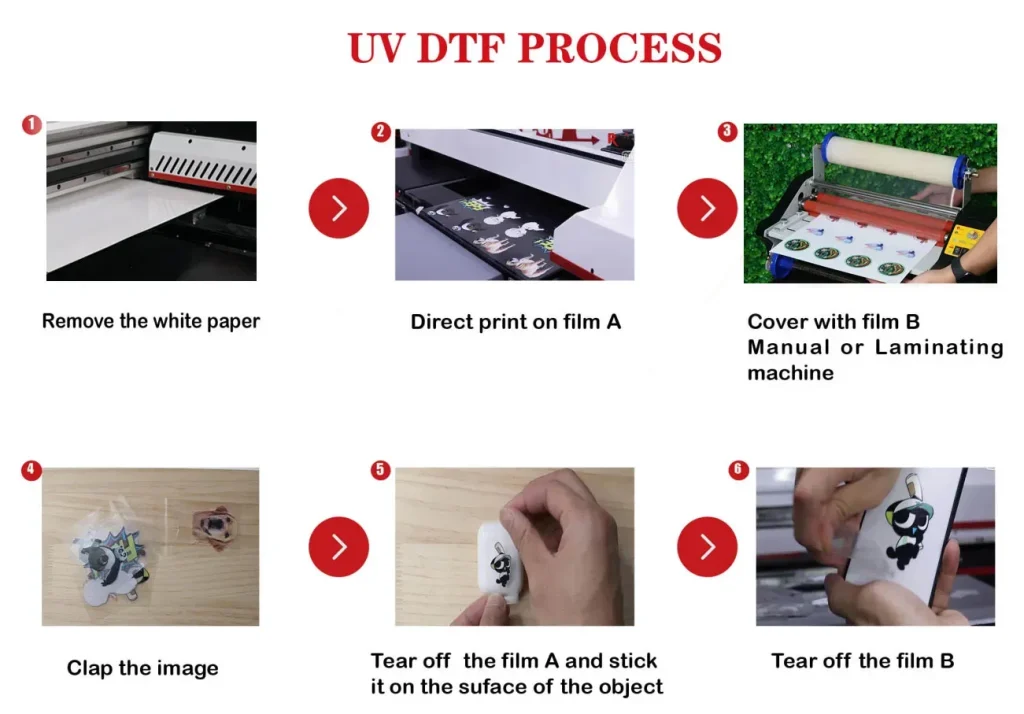

Understanding UV DTF Technology

UV DTF, or Ultra Violet Direct to Film, signifies a revolutionary shift in printing technology that takes full advantage of UV inks. These inks are notable for their immediate curing process, which not only ensures vibrant and precise prints but also minimizes drying times. As a result, businesses can produce high-quality designs at a faster rate than traditional methods. This makes UV DTF not just an efficient choice but also a cost-effective one, especially for large-scale production runs.

The technology behind UV DTF allows prints to be executed on diverse substrates, including textiles, hard surfaces, and plastics. This versatility is a game-changer for businesses looking to expand their product offerings and cater to various customer needs. With UV DTF, brands can achieve stunning visual effects and intricate designs that stand out in the competitive market.

The Eco-Friendly Advantages of UV DTF Printing

In recent years, eco-friendliness has become a significant focus for both consumers and manufacturers. UV DTF technology is at the forefront of this movement by utilizing environmentally friendly UV inks. These inks not only reduce waste during the printing process but also emit fewer volatile organic compounds (VOCs), making them safer for both the environment and human health.

Moreover, because prints are cured instantly with UV light, there is less energy consumption during the production process compared to traditional printing methods. This efficiency aligns well with the increasing demand for sustainable practices in the printing industry, allowing businesses to appeal to environmentally conscious consumers while reducing their carbon footprint.

Applications of UV DTF in Various Industries

UV DTF printing holds tremendous potential across multiple sectors due to its adaptability. For instance, in the fashion and apparel industry, UV DTF is transforming how companies create custom garments. Designers can produce vibrant prints on various fabrics quickly, allowing for rapid product turnover without compromising quality.

Similarly, the promotional product sector benefits significantly from UV DTF’s durability and vivid color reproduction. Items such as mugs, phone cases, and signage can be enhanced with high-quality prints that withstand the test of time and environmental factors, ensuring that promotional materials retain their appeal even in outdoor settings.

Challenges Faced with UV DTF Technology

Despite its many advantages, UV DTF technology does present certain challenges. One significant hurdle is the initial investment required to acquire UV DTF printers, which can be considerably more expensive than traditional printing setups. Smaller businesses, in particular, may find this barrier prohibitive, making it difficult to adopt this advanced technology.

Additionally, operating UV DTF printers requires specialized knowledge and skills. Understanding the intricacies of UV inks and the proper techniques for printing on varied substrates is essential for achieving optimal results. Businesses may need to invest in employee training, which adds to the overall cost of integrating this technology into their operations.

Exploring the Market Potential of UV DTF

As demand for personalized products continues to rise, so does the market potential for UV DTF technology. Industries such as fashion, advertising, and consumer goods are increasingly turning to UV DTF for its ability to produce unique and high-quality designs. This trend not only allows businesses to stand out in saturated markets but also caters to the growing consumer preference for custom, tailor-made products.

Market analyses show that the UV DTF industry is on a trajectory of rapid growth. With consistent advancements in printing technology and the rising popularity of eco-friendly solutions, companies that adopt UV DTF can position themselves advantageously by meeting consumer demands for quality and sustainability.

UV Inks and Their Role in Direct to Film Printing

UV inks play a pivotal role in the effectiveness of UV DTF printing technology. These inks differ from traditional inks in that they cure through exposure to ultraviolet light, which not only facilitates immediate drying but also enhances the vibrancy and durability of the prints. This unique property of UV inks allows businesses to produce high-quality, long-lasting prints, ideal for branding and promotional materials.

Furthermore, UV inks are less prone to fading when exposed to sunlight compared to conventional inks, making them a preferred choice for outdoor signage and promotional products. The ability to create rich and detailed artwork opens new avenues for businesses to engage their customers with visually striking offerings.

Frequently Asked Questions

What are the key benefits of using UV DTF printing technology?

UV DTF printing technology offers several benefits, including high-quality prints with vibrant colors, quick turnaround times thanks to rapid UV ink curing, and durability that resists wear and fading. Additionally, UV DTF is eco-friendly as it often utilizes sustainable inks and processes.

How does UV DTF compare to traditional direct to film printing?

UV DTF differs from traditional direct to film printing by using UV inks that cure instantly, allowing for better print quality and greater substrate versatility. This technology enables the printing on various materials such as textiles, plastics, and metals, whereas traditional methods may have limitations.

Can UV DTF be used for custom garment printing?

Yes, UV DTF is ideal for custom garment printing. It produces high-quality, vibrant prints that are durable and resistant to fading, making it perfect for personalized apparel and fashion items.

Is UV DTF printing an eco-friendly solution?

Absolutely! UV DTF printing is considered an eco-friendly printing technology as it uses UV inks that emit fewer volatile organic compounds (VOCs) compared to traditional inks. This aligns with the growing demand for sustainable practices in printing.

What challenges might businesses face when adopting UV DTF printing?

Businesses may encounter challenges such as higher initial setup costs for UV DTF printers compared to conventional methods. Additionally, the operation of UV DTF requires specialized knowledge in handling inks and substrates effectively.

What industries can benefit from UV DTF technology?

Various industries can benefit from UV DTF technology, including fashion and apparel for customized garments, promotional products, signage for long-lasting displays, and consumer goods like personalized phone cases and bottles.

| Characteristic | Description |

|---|---|

| High-Quality Prints | Exceptional print quality with vibrant colors and sharp details for customization and promotional items. |

| Eco-Friendly Innovations | Utilizes environmentally friendly inks and methods, supporting sustainable practices in printing. |

| Versatile Substrate Options | Can print on various surfaces, including textiles, plastics, and metals, expanding market opportunities. |

| Efficiency and Speed | Reduced curing time enhances production speed, ideal for businesses with tight deadlines. |

| Growing Market Potential | Strong demand for customized products drives the market growth for UV DTF technology. |

Summary

UV DTF is transforming the printing industry by offering revolutionary solutions that blend high-quality output with eco-friendly practices. This printing technology excels in versatility, enabling businesses to innovate and tailor products across multiple substrates. Additionally, with its rapid curing capabilities, UV DTF significantly enhances operational efficiency. As more industries recognize the benefits of sustainability and customization, UV DTF is positioned as an essential method for modern printing solutions that cater to evolving consumer needs.