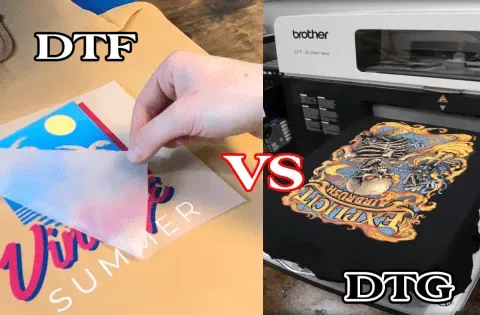

In the competitive realm of custom apparel, the debate on DTF vs. DTG printing is increasingly significant. As businesses strive to deliver high-quality, personalized items, understanding these two distinct printing methods can inform your decision-making process. DTF, or Direct to Film printing, offers unique advantages like versatility in fabric types and efficient production speeds, while DTG, or Direct to Garment printing, is known for its vibrant colors and detail. This article will help you navigate the printing methods comparison by highlighting key factors such as print quality, durability, and cost efficiency. With detailed insights into DTF printing advantages and DTG printing disadvantages, you will be better equipped to select the method that aligns with your business needs.

As the customization craze sweeps through the fashion landscape, two primary techniques—Direct to Film and Direct to Garment printing—have emerged as frontrunners. When making a choice between these technologies, it’s essential to evaluate the nuances of each to ensure your printed garments meet quality and durability expectations. Both methods serve the burgeoning market for personalized apparel, yet they cater to different production volumes and fabric types. Understanding their strengths can significantly impact your overall branding and client satisfaction. This overview not only illuminates the distinctions between DTF and DTG but also enriches knowledge about suitable applications for varied fabric materials.

DTF vs. DTG: Key Differences Explained

When evaluating the differences between DTF (Direct to Film) and DTG (Direct to Garment) printing methods, it’s crucial to understand their operational mechanisms and outcomes. DTF printing distinguishes itself by transferring designs from a film onto various garments using heat and pressure. This method allows for high versatility, accommodating different fabric types such as cotton, polyester, and blends. On the other hand, DTG printing utilizes sophisticated inkjet technology to apply water-based inks directly onto fabric, resulting in vivid and intricate designs primarily on lighter cotton materials. As a business owner, recognizing these distinctions can significantly influence your choice in production techniques.

Additionally, the market trends continuously evolve, reflecting the need for flexibility in printing techniques. DTF printing’s growing popularity can be attributed to its capacity for bulk production and compatibility with a diverse array of fabric, making it particularly advantageous in the customization landscape. Conversely, DTG printing remains a preferred method for those focusing on high-detail prints and artistic designs. The choice between DTF vs. DTG thus hinges not only on the desired visual outcome but also on the types of materials commonly used in production.

Understanding DTF Printing Advantages

DTF printing presents several advantages that make it appealing for businesses, particularly due to its versatility and high-quality output. One of the standout benefits is its ability to print on a wide variety of fabrics, including challenging materials like polyester and nylon. This capability expands creative opportunities for businesses looking to diversify their offerings, allowing them to cater to different market needs. Moreover, DTF technology works efficiently for both small and large batch orders, as it allows producers to create multiple transfers in a single run, enhancing production speed and cost efficiency.

Another notable advantage of DTF printing is the durability of prints. DTF transfers can withstand numerous wash cycles without significant fading or deterioration, making them ideal for items that will be worn frequently. This resilience adheres to customer demands for long-lasting apparel, giving businesses a competitive edge. In a world where customers often prioritize quality and durability, adopting DTF printing can prove beneficial in maintaining brand loyalty.

Evaluating DTG Printing Disadvantages

While DTG printing is renowned for its ability to produce high-quality, intricate designs, it does have some disadvantages that businesses should consider. One of the primary concerns is the limitation in fabric compatibility; DTG is predominantly effective on cotton and cotton blends. This restriction can hinder businesses that want to explore printing on a wider range of materials, such as synthetics or performance fabrics. Therefore, enterprises looking to expand custom apparel options might find this aspect of DTG a significant drawback.

Additionally, the production speed of DTG printing can be a notable disadvantage. The necessity of pre-treating garments and the intricate curing process can slow down output, making it less suitable for high-volume orders. As a result, businesses focused on bulk production may find themselves constrained in their operational capabilities when relying solely on DTG printing. Balancing these disadvantages against the method’s strengths is essential for achieving optimal results in the marketplace.

Comparative Analysis: Print Quality in DTF vs. DTG

When comparing print quality between DTF and DTG, it becomes evident that each method excels in distinct areas. DTG printing is typically celebrated for its ability to deliver vibrant colors and incredibly detailed designs. This method penetrates the fabric with inks, allowing for a soft feel that is particularly appealing for artistic and intricate patterns. For businesses that prioritize print resolution and artistic flair, DTG remains a strong contender in the custom apparel space.

However, DTF printing should not be underestimated. Although it may not always achieve the same level of detail as DTG, advancements in printing technology have allowed DTF to close the gap. It offers excellent vibrancy and is highly effective for a range of designs, particularly when dealing with larger graphics. Additionally, DTF’s superior fabric compatibility means that it can provide quality prints across multiple materials, making it a practical choice for businesses aiming for versatility.

Material Flexibility: A Crucial Factor in Printing Methods

Material flexibility is an essential factor for businesses when considering printing methods. DTF printing boasts unparalleled versatility, allowing it to be compatible with a diverse range of fabrics including cotton, polyester, and blends. This makes DTF an excellent solution for businesses looking to cater to different audiences and provide a variety of product offerings without being confined to specific fabric types. This flexibility not only enhances creativity but also enables companies to respond better to customer requests.

In contrast, DTG printing is primarily effective on cotton and its blend, which can limit options when it comes to fabric choice. For companies focusing on niche markets that require specialized materials or performance fabrics, DTG presents a significant limitation. Additionally, understanding the fabric compositions of products can assist business owners in making informed decisions about their printing processes. Ultimately, the flexibility of DTF can offer greater operational freedom and market adaptability.

Cost Efficiency in DTF and DTG Printing

Cost efficiency remains a vital consideration for businesses evaluating their printing options. DTF printing often emerges as the more economical choice for larger production runs. Its ability to print multiple transfers at once means that production costs are generally lowered, making it an attractive option for businesses focused on bulk orders. The setup and operational costs also permit effective budgeting, enhancing profitability in high-volume scenarios.

In contrast, while DTG printing can be more costly upfront due to the investment in specialized equipment, it is ideal for low-volume projects requiring high-quality, detailed prints. Businesses that prioritize customization and the delivery of unique apparel can find value in the premium nature of DTG, even if it entails higher costs per unit. Therefore, weighing the cost implications of each method against the business model and volume needs is pivotal for financial planning.

Frequently Asked Questions

What are the primary differences between DTF vs. DTG printing methods?

The primary differences between DTF (Direct to Film) and DTG (Direct to Garment) printing methods lie in their application and versatility. DTG prints directly on fabrics using water-based inks, making it ideal for lighter cotton materials. In contrast, DTF involves printing designs onto a film, which is then transferred onto various fabrics, including cotton and synthetics. This flexibility allows DTF to cater to a broader range of printing needs.

What are the advantages of DTF printing over DTG printing?

DTF printing offers several advantages over DTG printing, including material flexibility, faster production speed, and improved durability. While DTG is limited primarily to cotton, DTF works effectively on diverse materials such as polyester, nylon, and blends. Additionally, DTF allows for bulk transfer prints, speeding up the production process, and exhibits better wash resistance compared to DTG prints.

Is DTG printing suitable for complex and colorful designs compared to DTF?

Yes, DTG printing is particularly suitable for complex and colorful designs due to its ability to produce vibrant images with intricate details. The technology allows for direct ink application, ensuring rich color saturation. DTF can also produce bright prints but may not capture ultra-fine details as effectively as DTG, especially on textured surfaces.

What are the cost implications of choosing DTF vs. DTG for printing businesses?

Cost implications vary between DTF and DTG printing methods. DTG usually involves higher initial equipment investment but may be more cost-effective for small, detailed print runs. In contrast, DTF printing tends to be more economical for larger orders, as it allows for batch printing of transfers, decreasing the overall cost per print while maintaining quality.

How does durability compare between DTF and DTG prints over time?

Durability differs significantly between DTF and DTG prints. DTG prints can fade or deteriorate after multiple washes if not cured properly, often requiring extra care to maintain their quality. DTF prints, however, typically demonstrate superior durability and wash resistance when applied correctly, making them a reliable choice for long-lasting apparel.

Which printing method is faster for production, DTF or DTG?

DTF printing is generally faster for production compared to DTG. While DTG requires pre-treatment and curing for each garment, DTF allows for bulk transfer printing, enabling multiple designs to be prepared simultaneously. This efficiency makes DTF particularly advantageous for larger production runs, thereby accelerating turnaround times for businesses.

| Aspect | DTF (Direct to Film) | DTG (Direct to Garment) |

|---|---|---|

| Technology Overview | Prints onto a special film and transfers it to fabric; compatible with various materials. | Prints directly onto fabric using inkjet technology; best for lighter cotton fabrics. |

| Print Quality | Yields good quality and color vibrancy; slightly less detail on textured materials. | Excels in detailed and intricate designs, vibrant colors with a soft feel. |

| Material Flexibility | Works well on a range of fabrics including synthetic types. | Best for cotton and cotton blends; limited on synthetic materials. |

| Durability | Offers excellent wash resistance and retains quality over time. | Prone to fading over time; requires proper curing for longevity. |

| Production Speed | Allows for bulk printing and faster application on garments. | Typically slower due to pre-treatment and curing processes. |

| Cost Efficiency | More cost-effective for larger quantities and bulk orders. | Higher initial investment; more suited for low-volume, high-quality projects. |

Summary

In summary, DTF vs. DTG printing methods presents a pivotal choice for your business in the custom apparel industry. Understanding the distinctions in technology, print quality, material flexibility, durability, production speed, and cost efficiency can significantly influence your operations. While DTG is ideal for intricate designs on cotton fabrics and is excellent for low-volume custom prints, DTF provides versatility for various fabric types and is more efficient for larger production runs. Your decision should align with your specific business needs, ultimately enhancing your printing capabilities and customer satisfaction.