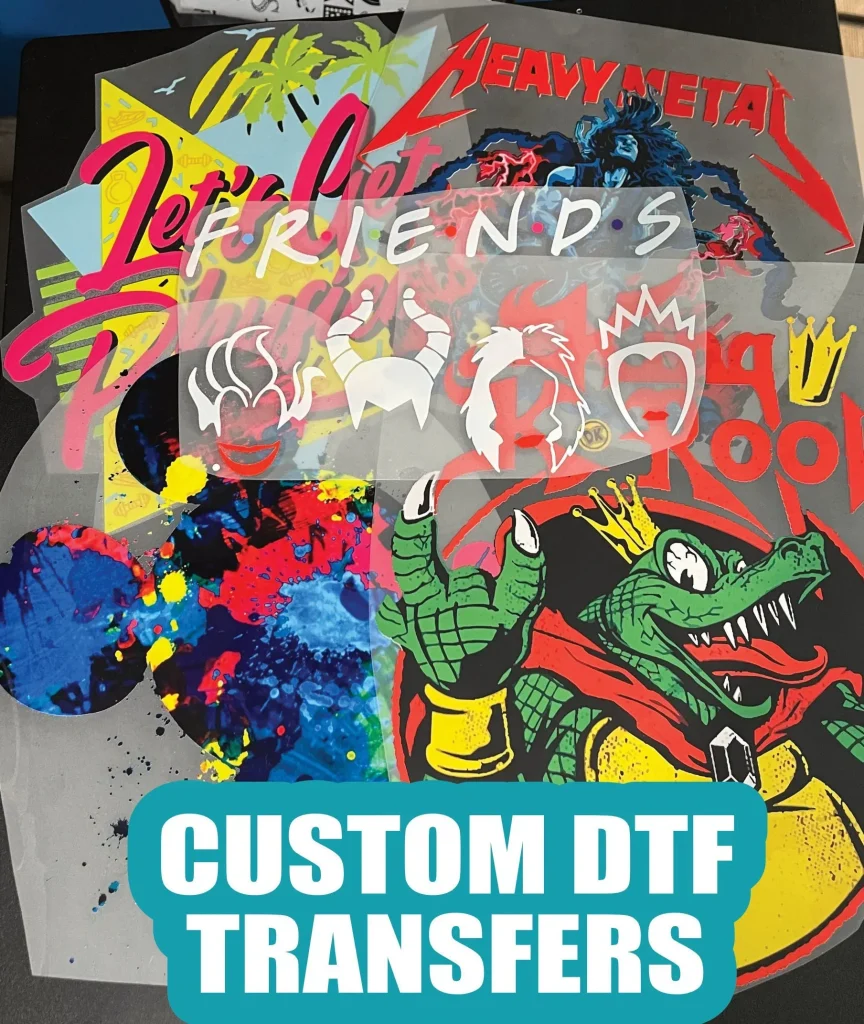

DTF transfers, or Direct-to-Film transfers, have emerged as a groundbreaking method in the custom apparel industry, enabling designers to create vibrant prints with unmatched detail and ease. With the DTF printing process, users can apply intricate designs onto various fabrics using a simple yet effective technique. In this guide, we’ll explore how to use DTF transfers to produce stunning, personalized clothing items that stand out. The benefits of DTF transfers are vast, from their versatility in material application to their cost-effective nature for small runs. Ready to dive into designing with DTF transfers? Let’s get started!

Direct-to-Film transfers, often referred to as DTF transfers, are reshaping how we approach fabric printing and design. This innovative technique allows for high-fidelity prints that can be seamlessly applied to a range of textiles, making it ideal for custom clothing lines. The process of using DTF includes several key stages, such as printing, applying adhesives, and transferring designs, ensuring that every intricate detail is captured. With the growing popularity of custom apparel and personalized fashion, understanding the various advantages of DTF printing becomes essential for aspiring designers. Whether you’re creating unique merchandise or enhancing your branding, mastering this technology can elevate your creative projects to a new level.

Understanding the DTF Printing Process

The DTF printing process is a modern method that involves several critical steps to produce high-quality prints. Initially, a design is printed on a special DTF transfer film using a specialized DTF printer with vibrant, water-based inks. This method enables intricate details to be captured, making it ideal for custom apparel, promotional items, and more. Understanding the DTF printing process helps ensure that designers can create vibrant products that stand out.

After printing, the process includes applying a hot-melt adhesive powder to bond the ink with the fabric during the transfer. This is a crucial part of DTF printing, as it directly affects the durability and quality of the final product. Knowing how the DTF printing process works allows for better management of customer expectations regarding print longevity and appearance.

How to Use DTF Transfers Effectively

To effectively use DTF transfers, designers must first focus on creating high-resolution artwork that translates well onto fabric. This involves using graphic design software to make sure the design is compatible with the DTF printing process, specifically formatted in CMYK color mode. A well-prepared design is essential for achieving the clarity and detail that DTF transfers promise.

Once the design is created, the printing process must be executed with precision. Ensuring the right printer settings and using high-quality water-based inks is another critical step in how to use DTF transfers effectively. By mastering these processes, creators can confidently produce high-quality, custom apparel that meets consumer demands.

The Advantages of DTF Transfer Technology

DTF transfer technology brings numerous benefits to the custom apparel industry. One major advantage is the versatility it offers; DTF transfers can be applied to various fabric types including cotton, polyester, and blends, making them suitable for a broad range of apparel items. This versatility helps brands meet customer needs without being limited by fabric type.

Another substantial advantage is the high-quality output produced by DTF transfers. The process allows for vibrancy in colors and intricate designs that elevate the visual appeal of custom apparel. This benefit not only enhances product offerings but also provides a competitive edge in the market, where quality often dictates consumer choices.

Creating Custom Apparel with DTF Transfers

Creating custom apparel with DTF transfers allows designers to showcase their creativity and establish a unique brand identity. The ability to produce low-volume, one-off designs inexpensively and effectively has made DTF transfers popular among small businesses and independent creators. By embracing this technology, designers can cater to niche markets while keeping production costs low.

The process of customizing apparel with DTF transfers involves careful planning and execution as each step contributes to the overall quality of the final product. From design creation to the careful application of the transfers, attention to detail ensures that the custom pieces not only look good but also last longer through multiple washes and wears.

Caring for Your DTF Printed Products

Caring for products printed with DTF transfers is crucial in maintaining their quality over time. To ensure longevity, customers should be advised to wash the garments inside out in cold water and avoid bleach and fabric softeners. This care routine helps preserve the vibrancy of the prints and extends the life of custom apparel.

Additionally, drying tips are essential for the upkeep of DTF printed items. It’s recommended to air dry or tumble dry on low heat to minimize any potential damage to the print. Proper care not only improves customer satisfaction but also enhances brand reputation by ensuring that the high-quality prints retain their appearance and durability.

Best Practices for DTF Transfer Application

When it comes to applying DTF transfers, following best practices is crucial for achieving the best results. Make sure to preheat the fabric before application to help with the adhesion and improve the overall outcome. Utilizing a heat press with the appropriate temperature and pressure settings will ensure that the transfers adhere seamlessly, preventing any lifting or peeling.

After pressing the transfer, it’s essential to let the garment cool down before peeling off the transfer film. This critical step helps to prevent any damage to the print and ensures that the design remains intact. Emphasizing these best practices will not only improve output quality but also increase the satisfaction level of customers who purchase the finished products.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing a design onto a special film that can be transferred onto different fabrics using heat. This process allows for vibrant, high-quality prints that work well with a variety of materials, making it popular in the custom apparel industry.

What is the DTF printing process and what makes it unique?

The DTF printing process includes several steps: designing in graphic software, printing onto transfer film using water-based inks, applying a hot-melt adhesive, and then curing the print before transferring it onto apparel with a heat press. Its ability to produce detailed and colorful designs on multiple fabric types sets it apart from other printing techniques.

How to use DTF transfers effectively on custom apparel?

To use DTF transfers effectively, start by creating a high-resolution design, print it onto the correct DTF film, apply adhesive powder, and then cure the film properly. Finally, use a heat press at the correct temperature and pressure to transfer your design onto custom apparel, ensuring vibrant, long-lasting results.

What are the benefits of using DTF transfers for custom apparel?

DTF transfers offer numerous benefits such as versatility across different fabric types, high-quality color reproduction, and the ability to print intricate designs easily. Additionally, they are cost-effective for small runs, making them ideal for custom apparel production without the high setup costs of other methods.

What should I consider when designing with DTF transfers?

When designing with DTF transfers, ensure that your design is high-resolution, formatted in CMYK color mode for accurate printing, and preferably simple yet clear to achieve the best transfer results. This attention to detail allows for optimal clarity and vibrancy in the final product.

How do I care for products made using DTF transfers?

To care for products made with DTF transfers, it is recommended to wash them inside out in cold water, avoid bleach and fabric softeners, and air dry or tumble dry on low heat. Following these guidelines will help maintain the quality and longevity of the vibrant designs.

| Step | Key Points |

|---|---|

| 1. Design Creation | Use graphic design software, ensure high resolution (300 DPI), CMYK color mode, and balance complexity in designs. |

| 2. Printing the Design | Print on the DTF transfer film using quality water-based inks, adjusting printer settings as per film specifics. |

| 3. Applying Adhesive | Evenly sprinkle hot-melt adhesive powder over wet ink and cure with heat for bonding enhancement. |

| 4. Curing the Print | Use a heat press or conveyor oven, following manufacturer recommendations for time and temperature. |

| 5. The Transfer Process | Position the cured film on the fabric and press with heat and firm but even pressure for optimal transfer. |

| 6. Peeling the Film | Allow cooling before peeling the film to prevent tearing; do so with precision. |

| 7. Caring for the Finished Product | Advise on washing instructions (inside out, cold water) and drying tips (air dry or low heat). |

| Advantages | Versatile, suitable for different fabric types, produces vivid colors, cost-effective for small runs. |

Summary

DTF transfers are revolutionizing the apparel industry through their capacity for high-quality, vibrant designs. This innovative printing method allows for remarkable detail and durability, appealing widely to both designers and consumers. Following the meticulous steps outlined above, from design creation to the final transfer, will ensure outstanding results that stand the test of time. Embracing DTF transfers can transform how you present your creative designs, making it a go-to choice for custom apparel production.