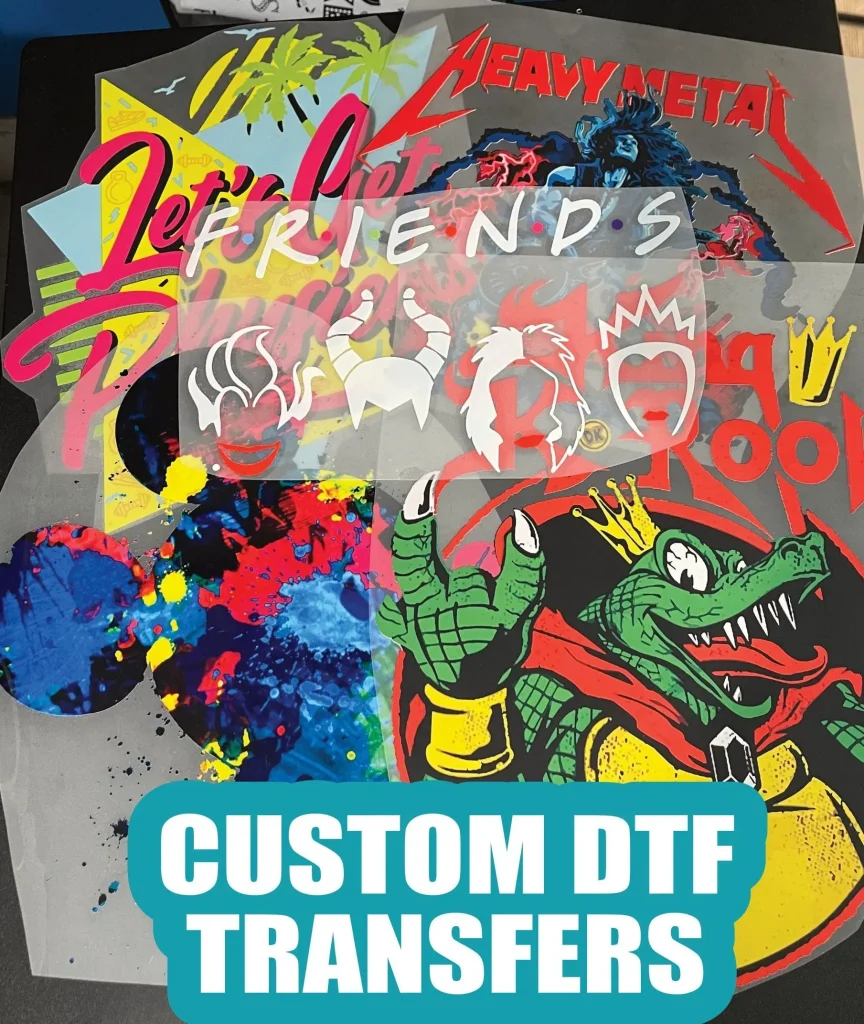

In the realm of custom apparel, DTF transfers have revolutionized the way designs are created and applied to fabrics. Standing for Direct to Film printing, this innovative technique allows vibrant colors and detailed imagery to be seamlessly transferred onto various materials, setting it apart from traditional vinyl printing methods. The versatility of DTF transfers opens the door for endless customization options, making them a favorite among small businesses and crafters looking to showcase unique designs. Whether you’re looking to create bespoke fashion pieces or eye-catching merchandise, DTF printing gives you the tools to bring your creative vision to life with stunning clarity. Dive into the world of heat press transfers and discover how this advanced technology can elevate your crafting game.

When it comes to contemporary printing techniques, transferring designs with Direct to Film (DTF) methods is gaining significant traction among DIY enthusiasts and professionals alike. This approach not only enhances the quality of custom apparel but also provides a user-friendly interface that simplifies the design process. As an alternative to traditional vinyl printing, DTF printing promises vibrant outcomes that are easily attainable with the right equipment and materials. The ability to apply intricate patterns and lively colors on various surfaces makes DTF a versatile choice for anyone looking to make a mark in the custom merchandise landscape. By employing heat press transfers effectively, users can achieve professional-level results that showcase their creativity and style.

Understanding the Basics of DTF Transfers

DTF transfers, or Direct to Film transfers, represent a groundbreaking technique in the world of fabric printing. This method involves printing designs onto a specialized film treated to interact effectively with inks, allowing for vibrant, intricate designs to be transferred to various fabrics. With DTF printing, apparel creators can achieve stunning visuals and vibrant colors that stand out, elevating their custom apparel offerings to new heights. The process is straightforward yet powerful, making it an attractive option for both beginners and seasoned professionals who wish to expand their printing capabilities.

One of the key benefits of DTF transfers is their versatility; this technique can be applied to multiple fabric types, including cotton, polyester, and even blends. Unlike vinyl printing, which requires specific materials, DTF printing allows for a wider array of fabric choices, catering to different markets and customer preferences. Furthermore, because DTF transfers apply a protective layer onto the printed design, they yield long-lasting results that can withstand wear and tear, making them ideal for both commercial apps and personal projects.

Key Tools and Equipment for DTF Printing

Investing in the right tools is crucial for anyone looking to master DTF transfers effectively. Essential equipment includes a high-quality DTF printer, which is specifically designed to deliver detailed and vibrant prints on the transfer film. Additionally, you will need DTF inks, which differ from standard inks as they are formulated to bond well with the transfer film and withstand the heat during the pressing process. A reliable heat press machine is also vital, as the success of the transfer greatly depends on the consistent application of heat and pressure.

Moreover, acquiring good DTF transfer film is essential for ensuring the best adhesion and durability of your prints. Different brands may offer varying qualities, so researching and selecting a trusted manufacturer will help you avoid common pitfalls. Lastly, do not overlook graphic design software; being proficient in programs like Adobe Illustrator or CorelDRAW can enhance your ability to create unique designs that are optimized for DTF printing. Ultimately, investing in quality equipment and software lays a solid foundation for your DTF transfer projects.

Techniques for Optimizing DTF Print Designs

When optimizing designs for DTF printing, one major consideration is image resolution. It is imperative to use high-resolution images, typically at least 300 DPI, to ensure clarity and sharpness in the printed output. Additionally, understanding color profiles is essential to maintain color consistency across different materials. Ensuring that your design files are in the RGB mode, which is ideal for digital applications, will make it easier to achieve vibrant colors in your prints.

Another important aspect is experimenting with design elements such as gradients and layering effects. Due to the unique capabilities of DTF transfers, artists can explore intricate designs that may not be possible with traditional vinyl printing. Be willing to test various inks and transfer techniques to tweak and perfect your outcomes. Regular practice will enable you to refine your skills and discover your artistic style in DTF printing.

Mastering Heat Press Techniques for DTF Transfers

The heat press is a game-changer in the world of DTF printing, as the effectiveness of your transfers highly relies on properly applying temperature and pressure. Experimenting with different heat settings on test materials allows you to find the ideal combination that produces the best results without damaging the fabric or the print. Generally, DTF transfers require medium to high heat settings, typically around 320°F to 340°F, for about 15-25 seconds, but these can vary based on the fabric type.

In addition to temperature, pressure plays a significant role in the transfer’s success. It’s crucial to ensure that your heat press applies even pressure across the entire area of the design. Uneven pressure can lead to incomplete transfers or poor adhesion, detracting from the quality of the finished product. Take time to adjust the pressure settings on your machine, and if necessary, consider using a pillow or foam pad for thicker fabrics to achieve that even contact.

Testing and Experimentation: Key to Success in DTF Printing

Testing various materials and techniques is essential for anyone looking to refine their DTF printing skills. As a beginner, dedicate regular time to experiment with different fabric types, inks, and heat press settings to see how they affect the final output. This hands-on experimentation not only helps you understand the nuances of DTF printing better but also aids in discovering your personal style and preferred techniques.

Furthermore, keeping a detailed record of your tests—including settings used, outcomes, and any challenges encountered—can serve as a valuable resource. This documentation not only helps in identifying what works best but also provides a benchmark for future projects. Embracing a mindset of experimentation will enhance your proficiency in DTF transfers and prepare you for any challenges you may face as you grow your custom apparel business.

Building a Community Around DTF Printing

Initially diving into the world of DTF printing can feel overwhelming; however, connecting with fellow enthusiasts can provide invaluable support and insight. Online communities, such as forums and social media groups, present excellent opportunities to share experiences, troubleshoot issues, and gather tips from seasoned DTF users. Engaging in these communities fosters a collaborative environment, where resources and knowledge are exchanged, making learning vastly more accessible.

Additionally, participating in local workshops or webinars not only facilitates hands-on training but also enhances networking opportunities with industry professionals. Building relationships within the DTF community can lead to mentorship possibilities, where experienced printers offer personalized guidance and encouragement. Ultimately, nurturing these connections can significantly accelerate your learning curve and deepen your understanding of DTF printing processes.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a modern printing method that allows vibrant designs to be printed on various fabrics and surfaces. In this process, your design is printed onto a special film, which is then coated with an adhesive. Afterward, the film is heat pressed onto the desired material, resulting in durable and high-quality prints.

What materials can be used for DTF printing?

DTF printing is versatile and can be applied to a variety of materials, including cotton, polyester, and even blends. This flexibility allows for custom apparel projects as well as designs on non-fabric items like bags and hats, expanding your design possibilities immensely.

How does DTF printing compare to vinyl printing?

Unlike vinyl printing, which involves cutting sheets of vinyl and applying them directly to fabric, DTF transfers utilize a film to print your designs in full color with intricate details. DTF offers improved vibrancy and durability, making it a preferred method for customized apparel.

What equipment do I need to get started with DTF transfers?

To successfully create DTF transfers, you will need a DTF printer, standard transfer films, adhesive powders, heat press equipment, and suitable graphic design software. Investing in quality supplies is crucial to ensuring high-quality results for your custom apparel.

Can I use DTF transfers on dark fabrics?

Yes, one of the benefits of DTF transfers is their ability to produce stunning results on dark fabrics. The printing process involves a white underbase layer, which enhances the vibrancy of colors on darker backgrounds, making it ideal for custom designs.

Where can I learn more about mastering DTF printing techniques?

There are numerous resources available for learning about DTF printing. Online platforms like YouTube offer instructional videos, while webinars and workshops provide hands-on experience. Additionally, engaging with community forums on social media can provide insights and support from other DTF printing enthusiasts.

| Key Components | Details |

|---|---|

| What are DTF Transfers? | DTF transfers utilize a specialized film to transfer designs onto fabrics, providing vibrant colors and durable finishes. |

| Key Developments | 1. Improved Print Quality: New printers enhance resolution and color vibrancy. 2. Diverse Applications: Suitable for various materials like fabrics and hard surfaces. 3. User-Friendly: Accompanied by beginner-friendly guides. |

| Learning Resources | 1. Instructional Videos: Step-by-step tutorials available online. 2. Webinars: Hands-on training from industry professionals. 3. Community Support: Online forums for sharing tips and experiences. |

| Key Considerations | 1. Equipment: Invest in reliable printers and supplies. 2. Software Proficiency: Understanding graphic design tools is essential. 3. Testing: Experimentation is crucial for mastering the technique. |

| Tips for Success | 1. Optimize Designs: Use high-res images and proper color settings. 2. Understand Pressing: Experiment with heat and time settings. 3. Regular Maintenance: Keep equipment clean to ensure quality. |

Summary

DTF transfers represent a revolutionary method for printing designs, allowing for vibrant and durable outcomes on various materials. As more resources and technologies become available, mastering DTF transfers is both accessible and rewarding for beginners and enthusiasts. By understanding the foundational aspects of DTF printing, utilizing the right tools and learning resources, and consistently experimenting, anyone can create stunning, personalized projects that showcase their creative vision. Whether you are a DIY enthusiast or seeking to enhance your small business offerings, embracing DTF transfers can open up a world of exciting design possibilities.