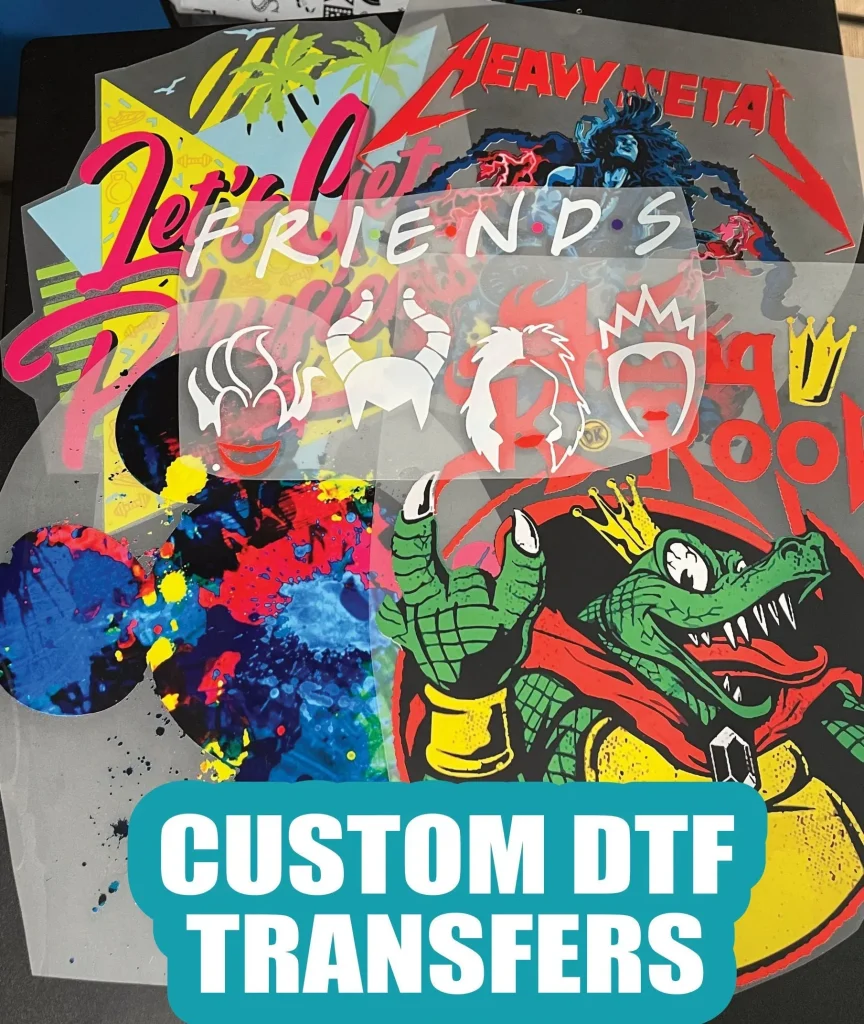

DTF transfers, or Direct to Film transfers, are becoming a go-to option for designers looking to produce stunning and vibrant prints on various fabrics. This innovative printing technique allows creators to achieve intricate designs that stand out and retain their quality over time. From clothing to accessories, learning how to use DTF transfers effectively can elevate your projects to new dimensions. In this guide, we will explore essential DTF design tips and techniques that not only enhance your creative process but also ensure durable and eye-catching results. Whether you’re a novice or a seasoned professional, mastering DTF printing opens a world of possibilities for your artistic expression.

Also known as direct-to-film printing, this method involves a special process that transfers detailed images onto fabric materials with remarkable accuracy. It’s a versatile approach that suits a broad range of applications, from custom apparel to home textiles, making it popular among both hobbyists and commercial enterprises. Understanding how to create DTF transfers effectively can significantly impact the vibrancy and longevity of your designs. With the right techniques and materials, you can achieve stunning results that appeal to a wide audience. Whether you’re interested in fashion, crafts, or merchandise production, mastering these alternative terms and methods can revolutionize your printing projects.

Understanding DTF Transfers: A Deeper Dive

Direct to Film (DTF) transfers are becoming an essential part of modern textile printing. This printing method involves transferring high-resolution designs onto a specialized film that can be heat applied onto a variety of fabrics. The beauty of DTF technology lies in its ability to reproduce intricate designs with vibrant colors, making it a favorite among custom apparel businesses. Unlike traditional methods, DTF printing leverages unique ink formulations that promote excellent adhesion and wash durability, allowing for stunning results that can withstand the test of time.

The DTF process starts by creating a digital design that is printed onto a film coated with a heat-sensitive adhesive. This layered approach allows for crisp details and vivid color saturation, which are crucial for today’s fashion trends. Once printed, the film is heat-pressed onto the fabric, creating a bond that ensures the image remains intact even after multiple washes. This versatility in application makes DTF transfers ideal not just for t-shirts, but also for hoodies, tote bags, and other fabric-based products.

Top Tips for Creating Stunning DTF Transfers

To create eye-catching DTF transfers, start by selecting the right materials. High-quality DTF films and inks play a substantial role in the outcome of your designs. By using reputable brands known for their vivid colors and strong adhesion properties, you increase your chances of producing professional-grade results. Tools like Adobe Illustrator can help you refine your designs, allowing for adjustments in colors and layouts that enhance the final product. Remember, a well-prepared design equals a higher quality transfer.

In addition to material selection, consider incorporating bold colors and strong contrasts in your designs. DTF printing showcases bright, saturated hues beautifully; thus, choosing colors that stand out against the fabric can greatly enhance the visual impact. Utilize solid colors that cover larger areas on your designs, as they not only transfer better but also create a striking, modern look. Designing with these principles in mind will maximize the effectiveness of your DTF transfers, ensuring they not only look great but also last.

Pre-Treatment Techniques for DTF Success

Pre-treatment of fabrics is a vital step to ensure successful DTF transfers. Before transferring your designs, clean and prepare your fabrics. Removing any dust or oils will create a clean surface for the transfer, significantly improving adhesion. Additionally, a brief heat pressing of the fabric before applying the film can help open up the fabric fibers, allowing for a better bond during the application of the transfer.

Implementing proper pre-treatment techniques can directly influence the longevity and quality of your designs. Providing your fabrics with a light heat press not only ensures they are flat and wrinkle-free but also prepares them to accept the DTF transfer more effectively. This process is crucial, especially for high-volume projects where consistency in application quality is required. By refining your pre-treatment approach, you can achieve stunning results that meet customer expectations.

Mastering DTF Printing Techniques

Getting acquainted with DTF printing techniques is essential for producing high-quality transfers. Start by adjusting your printer settings to match the specifications of DTF printing, which includes calibrating the thickness of the film and ink saturation levels. An accurate setup will prevent issues such as ink bleeding or poor adhesion, both of which can ruin an intended design. Regular maintenance of your printer is also critical; keeping the print heads clean will reduce downtime and increase the quality of your prints.

Additionally, understanding how to manage film passage through your printer can prevent misprints and material waste. Always monitor the film during the printing process, as even slight jams can lead to significant issues down the line. Being thorough in this stage of production lays the groundwork for ensuring that every transfer looks impeccable, maintaining the high standards expected by your clients.

Application Techniques for Flawless DTF Transfers

The application of DTF transfers greatly impacts the final product’s quality. To apply your transfers correctly, precise temperature and pressure settings on your heat press are crucial. Standard settings often fall around 315°F for 15-20 seconds, but it’s important to adjust these according to the fabric type and thickness. Incorrect settings can lead to poorly adhered designs or excessive heat damage that can ruin your fabric.

Additionally, ensure that you apply even pressure across the entire surface of the transfer. This ensures that the design adheres uniformly, preventing issues such as peeling or fading. Some heat presses have adjustable pressure settings, so familiarize yourself with these features to achieve the best results. The time spent fine-tuning your application will be well worth it in the form of high-quality designs that meet customer demands.

Caring for DTF Transfers to Ensure Longevity

Caring for DTF transfers is essential for preserving their vibrancy and quality over time. After application, allow the transfer to cool completely before peeling off the film; this step is crucial as it can affect the bond between the design and the fabric. Educating your customers about the proper care for DTF-printed garments can help them maintain the integrity of the prints, ultimately leading to greater satisfaction with your products.

Providing simple care instructions can enhance the longevity of DTF transfers. Recommend cold washing and air drying to preserve the colors and prevent unnecessary wear. Additionally, inform them to avoid using bleach or fabric softeners which can break down the adhesive used in the transfers. By ensuring your customers understand how to care for their items, you not only foster positive relationships but also protect the quality of your DTF printed products.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a specialized film that is later heat-pressed onto fabric. This innovative DTF printing technique allows for high-quality, vibrant images with excellent durability on a variety of textiles.

What are some effective DTF design tips to improve print quality?

To achieve stunning results with DTF transfers, focus on bold colors and solid design areas. Using high contrast in your designs enhances visibility on different fabrics. Utilizing professional software like Adobe Illustrator can also help refine your layouts for better transfer outcomes.

How can I create DTF transfers that last through multiple washes?

To ensure your DTF transfers endure, select high-quality films and inks, and pre-treat your fabric correctly. Proper application of the transfer under appropriate heat and pressure settings, followed by correct post-press care, will enhance durability.

Can I use DTF transfers on any type of fabric?

Yes, DTF transfers are versatile and can be used on various fabrics such as cotton, polyester, and their blends. This adaptability makes DTF printing a popular choice among crafters and businesses looking to print detailed designs.

What are standard heat press settings for DTF transfers?

When applying DTF transfers, standard heat press settings typically range from 315°F for 15-20 seconds. However, it’s important to check the specific requirements for each fabric type to ensure optimal transfer results.

What advancements are currently influencing DTF printing technology?

Recent advancements in DTF printing technology include enhanced ink formulations that improve color fidelity and adhesion on fabrics, as well as machine advancements aimed at increasing production efficiency without compromising quality.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | Printing designs on special film to be heat-pressed onto fabric. |

| Key Advantages | High quality, versatility on various textiles, and durable designs. |

| Tips for DTF Success | Choose quality materials, focus on designs, pre-treat fabrics, set printer correctly, apply temps accurately and follow curing processes. |

| Latest Developments | Enhanced ink formulations and faster production times improving efficiency. |

Summary

DTF transfers are a revolutionary method in the world of fabric printing, combining quality, durability, and versatility to create stunning designs effortlessly. The process involves a careful selection of materials, precise design strategies, and optimized application techniques, ensuring that the end results are not only visually striking but also long-lasting. By staying up to date with the latest advancements in DTF technology and implementing the recommended tips, both beginners and seasoned designers can unlock the full potential of DTF transfers, elevating their print projects to professional standards.