DTF Transfers, or Direct to Film Transfers, are quickly revolutionizing the landscape of graphic printing by delivering high-quality results with exceptional versatility. Utilizing advanced heat transfer technology, this innovative method allows for detailed designs to be transferred onto a wide array of fabrics, becoming a favorite among custom apparel brands. As one of the latest breakthroughs in printing innovations, DTF printing processes are gaining traction for their efficiency and vibrant color output. Businesses are increasingly adopting DTF transfers not only for bulk production but also for bespoke designs tailored to individual preferences. This trend indicates a significant shift towards more personalized graphic solutions in the dynamic world of modern printing.

The emergence of Direct to Film applications is a game-changer in the realm of textile decoration and graphic design. Known for its ability to produce high-resolution images with vivid colors, this modern printing technique is becoming synonymous with custom-fabric solutions and heat-applied transfers. The evolution in transfer technology facilitates a seamless blending of creativity and practicality, making it indispensable for artists and apparel designers alike. With the DTF printing method, creators can easily produce intricate designs that resonate with contemporary consumer trends, enhancing the customization experience while maintaining production efficiency. As such, DTF printing represents a significant leap forward in modern printing practices.

Understanding the DTF Printing Process

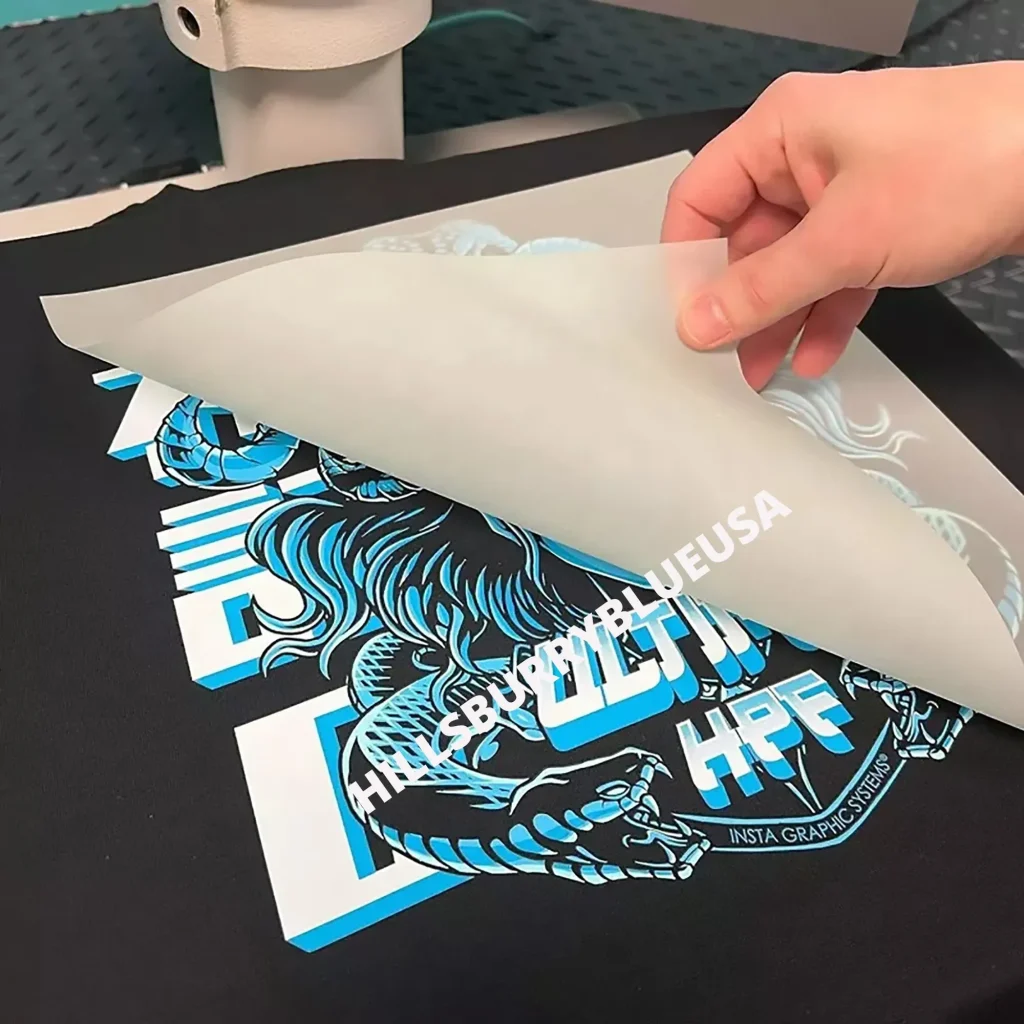

DTF printing, or Direct to Film printing, is a cutting-edge technique that allows for the transfer of high-quality graphics onto textiles. This process begins with printing the desired design onto a specialized film using advanced heat transfer technology. Once the design is printed, it is covered with a powder adhesive which is then cured before being pressed onto the fabric using heat and pressure. This method provides a durable and vibrant print that adheres effectively to a variety of fabrics, from cotton to polyester blends, making DTF printing a versatile choice for custom apparel.

One of the key advantages of DTF printing is its ability to produce detailed designs with a wide color gamut. Unlike traditional graphic printing methods, DTF can achieve complex images with gradients and subtleties that are crucial for professional apparel branding. With the continuous improvements in DTF technology, businesses can now opt for more personalized printing solutions, facilitating unique designs that cater to niche markets and individual preferences.

The Advantages of DTF Transfers over Traditional Methods

DTF transfers present numerous benefits when compared to conventional methods like screen printing or direct-to-garment printing. One major advantage is the quality of the finished product; DTF transfers can yield vibrant colors and intricate details that are often difficult to achieve with other technologies. This allows businesses to create visually appealing custom apparel that stands out in a competitive marketplace. Furthermore, DTF transfers are ideal for short runs and customized orders without the need for extensive setup costs.

Another significant benefit of DTF printing is its efficiency and flexibility. The DTF process enables quicker production times and allows for a diverse range of fabric applications, ensuring that businesses can adapt swiftly to changing customer demands. This adaptability not only streamlines workflows but also enhances customer satisfaction as orders can be fulfilled quickly without compromising on quality.

Innovations Driving DTF Transfers Towards the Future

Recent innovations in DTF technology are powering its rise within the graphic printing sector, with notable advancements such as improved printer capabilities and enhanced ink formulations. This ongoing progress is evident in products like the Insta DTF heat transfer, which showcases advancements in vibrancy and adherence, addressing common pain points associated with graphic applications. As these innovations become widely adopted, they are set to redefine the standards of quality and performance within the printing industry.

In addition to hardware improvements, software innovations and printing techniques are also evolving in the DTF space. New printing applications are being developed that allow users to easily create and modify designs, thereby granting them more control over their projects. With these advancements, DTF transfers are increasingly seen as a future-proof solution for businesses seeking high-quality, customizable graphic printing services.

The Impact of DTF Transfers on Custom Apparel Brands

For custom apparel brands, DTF transfers present an appealing option that aligns with current consumer trends toward personalization. The ability to produce vibrant designs on-demand caters to a growing demand for unique and tailored products. This flexibility allows brands to embrace seasonal designs or special collections without the high costs typically associated with bulk screen printing.

Additionally, DTF transfers can contribute to sustainability within the fashion industry. By enabling smaller production runs, brands can minimize waste associated with overproduction and excess inventory. As environmentally conscious consumers increasingly favor brands that prioritize sustainability, the use of DTF transfers can enhance a brand’s appeal by demonstrating a commitment to responsible production practices.

Maximizing Efficiency: How DTF Transfers Streamline Production

DTF transfers significantly streamline production processes for businesses in need of custom apparel. The efficiency of the DTF printing process shortens turnaround times, allowing companies to respond quickly to orders without sacrificing quality. The ease of applying DTF transfers—where designs can be directly printed onto films and transferred in one step—promotes a more organized workflow that reduces labor costs and increases overall output.

Furthermore, with DTF printing, there is minimal waste generated during production. The ability to print designs directly onto films means that brands can produce only what is necessary, eliminating the excess material typically associated with traditional methods. This efficiency aligns well with the modern emphasis on lean manufacturing practices, which prioritize reducing waste while maximizing productivity.

Why DTF Transfers Are Set to Dominate the Printing Landscape

As the graphic printing industry continues to evolve, DTF transfers are poised to become a dominant player, thanks to their innovative approaches and growing adoption among businesses. With significant advancements in printing technology and vibrant transfer capabilities, DTF offers significant advantages over traditional methods. This trend is further propelled by increased investment in DTF technology by leading printing companies, ensuring ongoing improvements in print quality and efficiency.

Moreover, the rise of e-commerce has created a surge in demand for customized products. As consumers increasingly seek unique and personalized apparel, DTF transfers provide a flexible solution that aligns with these preferences. The combination of quality, versatility, and cost-effectiveness unique to DTF printing will undoubtedly sustain its growth and solidify its role in shaping the future of graphic printing.

Frequently Asked Questions

What are DTF Transfers and how do they work in graphic printing?

DTF Transfers, or Direct to Film Transfers, are a modern graphic printing technique where designs are printed onto a special film and then heat-pressed onto various fabric materials. This method allows for vibrant, high-quality prints on custom apparel, making it a rapidly growing choice among graphic designers and brands.

Why are DTF Transfers becoming popular in custom apparel production?

DTF Transfers are gaining popularity in the custom apparel sector due to their exceptional print quality and versatility. They can be applied to a wide range of fabrics including cotton, polyester, and blends, making them suitable for everything from uniforms to personalized items. Their efficient production process also caters to the growing demand for custom designs.

What advantages do DTF Transfers have over traditional graphic printing methods?

DTF Transfers offer several advantages over traditional graphic printing techniques. They provide superior print quality with rich colors and fine details while allowing for quick turnaround times. Additionally, DTF technology is more cost-effective for small runs and custom designs, making it accessible for businesses of all sizes.

How does the DTF printing process enhance efficiency in custom orders?

The DTF printing process enhances efficiency by streamlining production workflows. It allows for quick setup and fast turnaround, accommodating both bulk orders and one-off items without sacrificing quality. This efficiency is essential for businesses in the fast-paced custom apparel market.

What recent innovations are shaping the future of DTF Transfers in graphic printing?

Recent innovations in DTF Transfers include enhanced heat transfer technologies and new product launches, such as the Insta DTF heat transfer by Insta Graphic Systems. These advancements improve print vibrancy and durability while expanding the accessibility of DTF technology for both large brands and small crafting businesses.

Are DTF Transfers a cost-effective solution for small businesses?

Yes, DTF Transfers provide a cost-effective solution for small businesses. They eliminate the need for costly setups and high minimum order quantities associated with traditional methods, allowing for affordable production of high-quality custom apparel, even in small runs.

| Key Point | Description |

|---|---|

| DTF Transfers Introduction | DTF Transfers employ a specialized technique to print designs onto a film that is then transferred to fabric using heat and pressure. |

| Revolutionary Product Launch | The Insta DTF heat transfer by Insta Graphic Systems enhances vibrancy and durability, making it ideal for custom apparel. |

| Emerging Market Leaders | Companies like Sam’s DTF Transfers are leading the way by offering fast, high-quality transfer services. |

| Marketplace Innovations | DTFPrinter has launched custom transfer printing experiences, catering to crafters and creators. |

| Industry Showcases | Events such as the DTF Expo Show highlight technological advancements in DTF printing. |

| Quality and Versatility | DTF transfers can be applied to a variety of materials, offering high-quality prints with rich colors. |

| Efficiency | DTF printing supports quicker turnaround times for custom orders, enhancing customer satisfaction. |

| Cost-Effectiveness | DTF technology allows for affordable production in small runs without excess waste. |

Summary

DTF Transfers are positioned at the forefront of graphic printing, offering innovative solutions that cater to a diverse array of industries. With advancements in technology and rising market demands, DTF transfers bring vibrant and high-quality printing to the forefront, making them an essential tool for businesses aiming for efficiency and cost-effectiveness. As brands continue to innovate and enhance their offerings, DTF transfers are securing their role as the preferred choice in the future of graphic printing, ensuring that both customization and quality remain a top priority.