DTF transfers, or Direct-to-Film transfers, are quickly emerging as a leading technology in the world of fabric printing. This innovative method allows for high-quality, vibrant designs to be easily transferred onto various fabric types, making it a versatile choice for custom apparel and merchandise. As the demand for personalized designs continues to grow, DTF printing trends reveal a significant shift toward this efficient and user-friendly process. Combining durability with stunning visual impact, DTF technology is perfect for both small businesses and larger commercial operations. In this article, we’ll explore how DTF transfers are shaping the future of fabric printing and their incredible potential.

Also known as direct-to-film printing, DTF transfers represent a groundbreaking shift in the realm of fabric decoration and customization. This modern printing technique utilizes film to create stunning images that can be seamlessly applied to a wide array of textiles, from casual wear to promotional products. The rise of custom transfers has revolutionized how we think about personalizing fabrics, allowing creators to achieve vivid colors and intricate patterns effortlessly. As we dive into the particulars of DTF technology, we will uncover the fundamental benefits and future prospects that make it a frontrunner in fabric printing solutions.

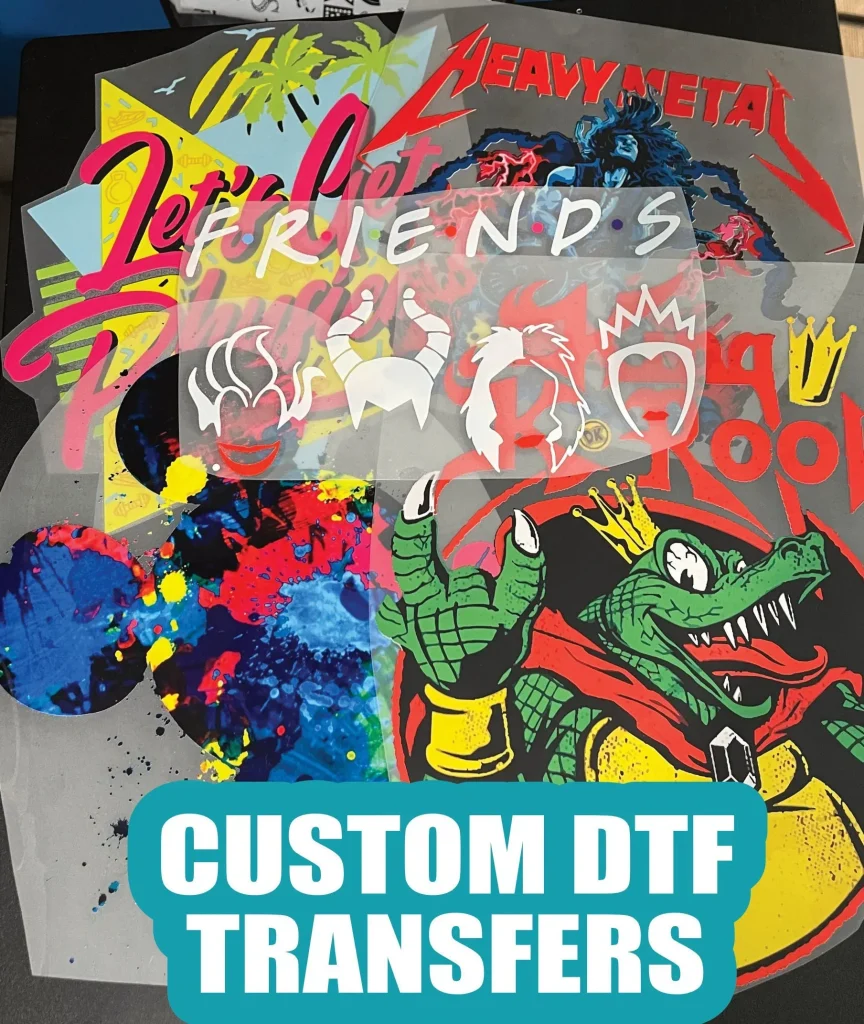

The Advantages of DTF Transfers in Modern Fabric Printing

DTF transfers offer a plethora of advantages that make them an ideal choice for modern fabric printing. One of the primary benefits is their versatility. Unlike traditional methods, DTF printing excels on a variety of fabric types including cotton, polyester, and blends. This flexibility allows businesses and individuals to customize everything from t-shirts to bags, making it easier to cater to diverse consumer needs. Furthermore, the vibrant colors produced through DTF technology ensure that designs pop, whether they’re printed on light or dark fabrics.

Another notable advantage is the exceptional durability of DTF prints. These transfers maintain their quality after multiple washes, which is particularly important for clothing that needs to withstand daily wear and cleaning. For businesses producing custom apparel, this durability translates into satisfied customers who enjoy their products longer. Thus, incorporating DTF transfers not only enhances product appeal due to their vivid details but also elevates customer retention through lasting quality.

Frequently Asked Questions

What are DTF transfers and how do they work in fabric printing?

DTF transfers, or Direct-to-Film transfers, involve printing images onto a specialized film which is then heat-pressed onto various fabrics. This technique allows for vibrant colors and durable designs on materials like cotton and polyester, making it a versatile option for custom transfers.

Why is DTF printing gaining popularity in the fabric printing industry?

DTF printing is rapidly gaining traction due to its ability to produce full-color, high-quality prints on a wide range of fabrics. The technology is user-friendly, making it appealing for small businesses and individual crafters looking to create custom apparel and merchandise.

How do DTF transfers compare to other fabric printing technologies?

Compared to traditional printing methods like sublimation, DTF transfers are more versatile, allowing for printing on dark fabrics without compromising color vibrancy. DTF technology also simplifies the setup process, making it a preferred choice for small business owners.

What are some current trends in DTF printing technology?

Current DTF printing trends include the rise of eco-friendly inks and materials, increased equipment investments for larger format printing, and the introduction of compact DTF printers suitable for home use, catering to the increasing demand among creatives and small businesses.

Can DTF transfers be used for both personal and commercial projects?

Absolutely! DTF transfers are perfect for both personal and commercial projects. They offer excellent versatility and durability, making them ideal for customized clothing, promotional items, and even intricate designs for various fabric types.

What benefits do DTF transfers provide for small business owners?

DTF transfers provide numerous benefits for small business owners, including the ability to create high-quality custom designs with minimal investment. The accessibility of supplies and user-friendly equipment allows entrepreneurs to offer diverse product ranges without the steep learning curve associated with traditional printing methods.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A printing process where images are printed on film and transferred to fabric using heat and pressure. |

| Versatility | Can be used on various fabric types, including cotton, polyester, and blends. |

| Vibrant Color | Produces sharp, vibrant images on both light and dark fabrics. |

| Durability | Excellent durability and washability, maintaining designs after washes. |

| Growing Popularity | Companies are investing heavily in DTF technology, reflecting its increasing demand. |

| DTF vs. Other Technologies | More versatile than sublimation, allowing for full-color prints on any fabric. |

| Ideal for Small Businesses | Compact A3-sized printers enable home-based entrepreneurs to start printing. |

| Future Prospects | Anticipated trends include sustainable practices and improved printing technologies. |

Summary

DTF Transfers are revolutionizing the fabric printing industry by offering unmatched versatility, vibrant color output, and durable prints. This technique, where images are printed on a specialized film and transferred to fabric, stands out for its ability to be applied to a variety of fabrics, including both light and dark materials. As the technology gains traction, it is becoming increasingly popular among small business owners and crafters due to its accessibility and cost-effectiveness. The future of DTF printing looks promising, with advancements poised to enhance both eco-friendliness and efficiency in production. Overall, DTF transfers are not just a trend; they are shaping the future of fabric printing, attracting creatives and professionals who seek high-quality results.