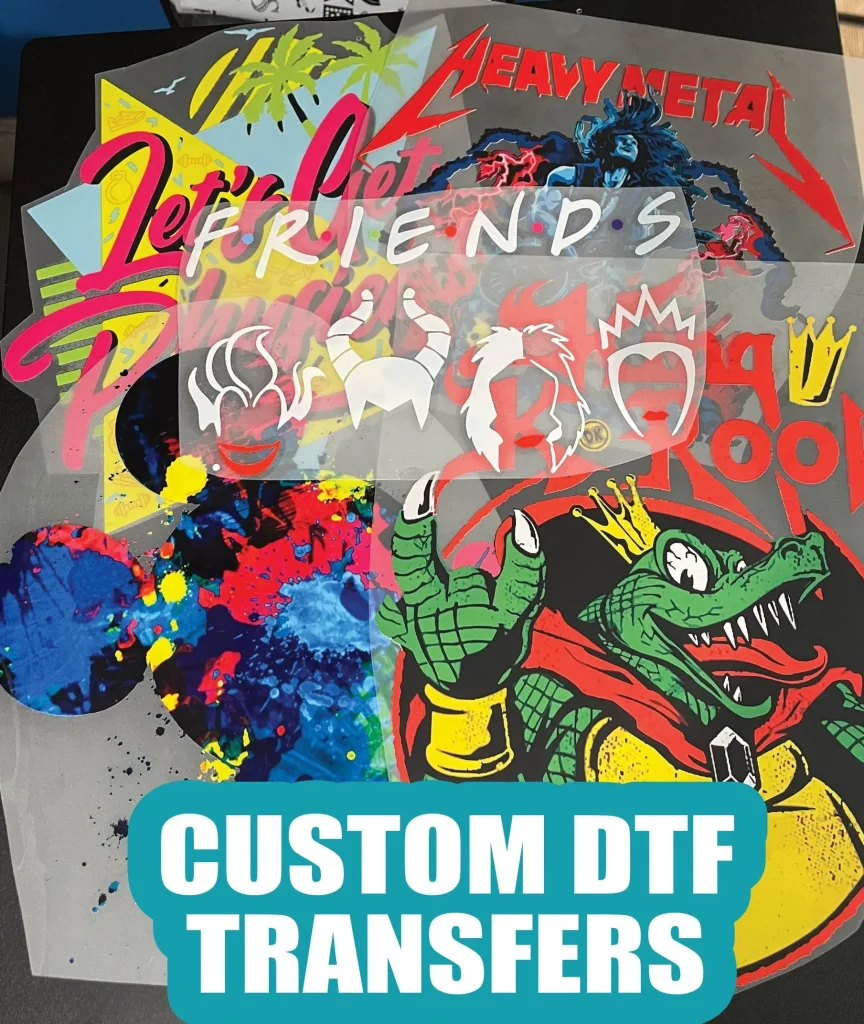

DTF transfers, or Direct-to-Film transfers, have emerged as a groundbreaking breakthrough in the custom printing landscape, significantly enhancing how businesses engage with their clients. This innovative technology provides vibrant and high-quality prints across various textiles, making it a favored choice for custom merch production. As sustainability becomes a paramount concern for consumers, DTF technology stands out, offering eco-friendly printing solutions that align with contemporary values. The versatility and efficiency of DTF transfers cater to changing consumer preferences, allowing businesses to adapt swiftly to trends in custom printing. In this article, we will delve deeper into the many benefits and future potential of DTF transfers, illustrating why they are reshaping the industry.

When exploring innovative printing methods, Direct-to-Film technology offers an alternative route for businesses looking to enhance their custom printing capabilities. Known for its adaptive applications, these transfer methods enable companies to create personalized products with stunning detail and color vibrancy on various fabrics. Dubbed DTF printing, this technique not only streamlines the production process but also integrates sustainable printing practices that appeal to today’s eco-conscious consumers. As the demand for customized merchandise rises, understanding the advantages and insights into this printing technology becomes crucial for industry players aiming to thrive in a competitive market. Join us as we uncover the exciting attributes of DTF transfers and their evolutionary impact on the custom merchandise sector.

Understanding Direct-to-Film (DTF) Technology

Direct-to-Film (DTF) technology represents a significant leap forward in the custom printing sector. Unlike traditional methods that often require extensive setup and materials, DTF printing streamlines the entire process into manageable steps. By utilizing specially coated films and innovative adhesives, printers can apply vibrant and intricate designs onto a wide array of fabrics. This adaptable technology caters to everything from casual wear to promotional products, making it an essential tool for any business looking to expand its merchandise offerings.

Moreover, DTF transfers boast remarkable durability compared to other printing techniques. They resist fading and cracking, ensuring that prints retain their quality even after multiple washes. This resilience is crucial for businesses that strive to deliver products that stand the test of time, especially in competitive markets. Embracing DTF technology not only enhances product quality but also reinforces brand reliability in the eyes of consumers.

The Versatility of DTF Transfers in Custom Printing

One of the standout features of DTF transfers is their exceptional versatility. They can be applied to a wide range of fabrics, including cotton, polyester, and various blends, making them ideal for custom apparel, accessories, and home textiles. This flexibility allows businesses to cater to diverse markets, from sports teams seeking customized gear to arts and crafts enthusiasts looking for unique pieces.

Additionally, DTF transfers can easily accommodate detailed designs and vibrant colors, which is crucial for brands looking to differentiate themselves in a crowded marketplace. This adaptability and high-quality output empower businesses to thrive by attracting a broader audience and meeting specific consumer needs. Ultimately, the versatility of DTF technology paves the way for innovative product developments that resonate with target demographics.

Sustainable Practices in DTF Printing

As sustainability becomes a priority for many consumers, DTF printing technology aligns itself with eco-friendly practices increasingly sought in the custom printing industry. Utilizing water-based inks and recyclable transfer films, DTF processes significantly reduce the environmental footprint associated with traditional printing methods. By adopting these sustainable practices, businesses can appeal to environmentally conscious customers and enhance their market position.

Moreover, the print-on-demand nature of DTF transfers empowers companies to create only what is necessary, minimizing waste and excess inventory. This efficiency not only leads to cost savings but also fosters a more sustainable operational model. In a world where consumers value brands that prioritize sustainability, implementing DTF technology positions businesses as leaders in responsible manufacturing.

Cost-Effectiveness of DTF Transfers for Small Businesses

For small businesses and startups, cost-effectiveness is a crucial factor when considering the adoption of new technologies. DTF transfers require lower initial investments compared to traditional screen printing setups, making it an accessible choice for many entrepreneurs. With DTF, businesses can keep their overheads manageable while still delivering high-quality, customized products to their customers.

Additionally, the efficiency of the DTF process further contributes to cost savings. The quick turnaround time means that businesses can fulfill orders rapidly, increasing customer satisfaction and repeat business. This ability to adapt and provide timely services enhances profit margins, making DTF printing a viable option for companies seeking sustainable growth in the custom printing landscape.

Real-Time Customizations with DTF Technology

In today’s fast-paced retail environment, customers demand personalized products that cater to their unique tastes. DTF transfers excel in providing real-time customization options, allowing businesses to swiftly adapt designs to meet specific client requests. This agility enables brands to offer tailored merchandise—from custom clothing for events to personalized promotional items—without long lead times, which are often a barrier in traditional printing methods.

Furthermore, the capability to efficiently produce small batches of customized goods allows businesses to tap into niche markets and cater to specific consumer demands. By utilizing DTF transfers, companies can foster customer loyalty by providing unique offerings that align with individual preferences, ultimately contributing to a differentiated brand identity in the highly competitive custom printing sector.

Anticipating the Future of DTF Printing

The future of DTF printing technology appears promising as advancements continue to drive its evolution. With innovations that focus on enhancing print quality, speed, and resource efficiency, businesses are likely to see expanded adoption of DTF methods. These ongoing improvements not only solidify DTF technology’s standing in the custom printing landscape but also introduce new opportunities for creative expression and product differentiation.

As market trends shift further toward personalization and sustainability, businesses that embrace DTF technology will be well-positioned to respond effectively. The ability to adapt to consumer demands for unique and eco-friendly products will ensure that DTF transfers remain a relevant and essential tool for businesses in the custom printing industry for years to come.

Frequently Asked Questions

What are DTF transfers and how do they work in custom printing?

DTF transfers, or Direct-to-Film transfers, are a revolutionary custom printing method that involves printing designs onto specialized transfer film, applying an adhesive powder, and using heat to transfer the image onto fabrics. This process allows for high-quality prints on various textiles, making DTF a popular choice in the custom printing industry.

What are the advantages of using DTF technology for custom merch?

DTF technology offers numerous advantages for custom merch, including versatility in printing on different fabrics, ease of use for both beginners and experienced printers, and eco-friendly options through sustainable inks and adhesives. Additionally, DTF allows for real-time customizations, enhancing customer satisfaction and enabling quick responses to unique demands.

How does DTF printing compare to traditional screen printing methods?

DTF printing differs from traditional screen printing in its process and versatility. Unlike screen printing, which can be limited by the colors and complexity of designs, DTF transfers produce vibrant, high-quality prints on a wide range of fabrics without the need for extensive setup or preparation, making it a cost-effective and efficient solution in the custom printing sector.

Is DTF printing considered a sustainable option in the custom printing industry?

Yes, DTF printing is considered a sustainable option in the custom printing industry. Manufacturers are focusing on eco-friendly inks and adhesives, and the ability to print on demand reduces waste. This aligns DTF technology with the growing consumer preference for environmentally responsible printing practices.

What challenges might businesses face when adopting DTF transfers?

While DTF transfers offer many benefits, challenges include the initial investment cost for equipment and the learning curve associated with mastering the technology. However, the long-term advantages such as reduced operational costs and high-quality prints often outweigh these hurdles, making DTF a viable option for many businesses.

What is the market outlook for DTF transfers in the coming years?

The market outlook for DTF transfers is promising, with projections indicating a significant compound annual growth rate. As the technology advances and more businesses adopt DTF printing, it is expected to lead to improvements in printing quality, speed, and cost-effectiveness, solidifying its place at the forefront of the custom printing industry.

| Key Features of DTF Transfers | Description |

|---|---|

| 1. Ease of Use | DTF transfers simplify the printing process, making it accessible to both newcomers and experienced printers. |

| 2. Eco-Friendly Options | DTF technology incorporates eco-friendly inks and adhesives, aligning with sustainability goals. |

| 3. Real-Time Customizations | DTF allows businesses to offer personalized products quickly, enhancing customer satisfaction. |

| 4. Promising Market Outlook | Projected CAGR of over 20% suggests a strong future for DTF technology in the printing market. |

| 5. Challenges and Considerations | Initial equipment costs and a learning curve exist, but the benefits often outweigh these hurdles. |

Summary

DTF transfers are a game-changing advancement in the custom printing industry, rapidly transforming how businesses create and deliver printed products. This innovative technology provides a simple yet efficient way to produce high-quality prints on various fabrics, addressing modern consumer demands for personalization and sustainability. Companies that leverage DTF transfers can respond quickly to customer needs while minimizing waste through on-demand printing. As the market for DTF continues to grow, businesses embracing this technology are well-positioned to improve their operations and enhance their competitive edge in an evolving marketplace.