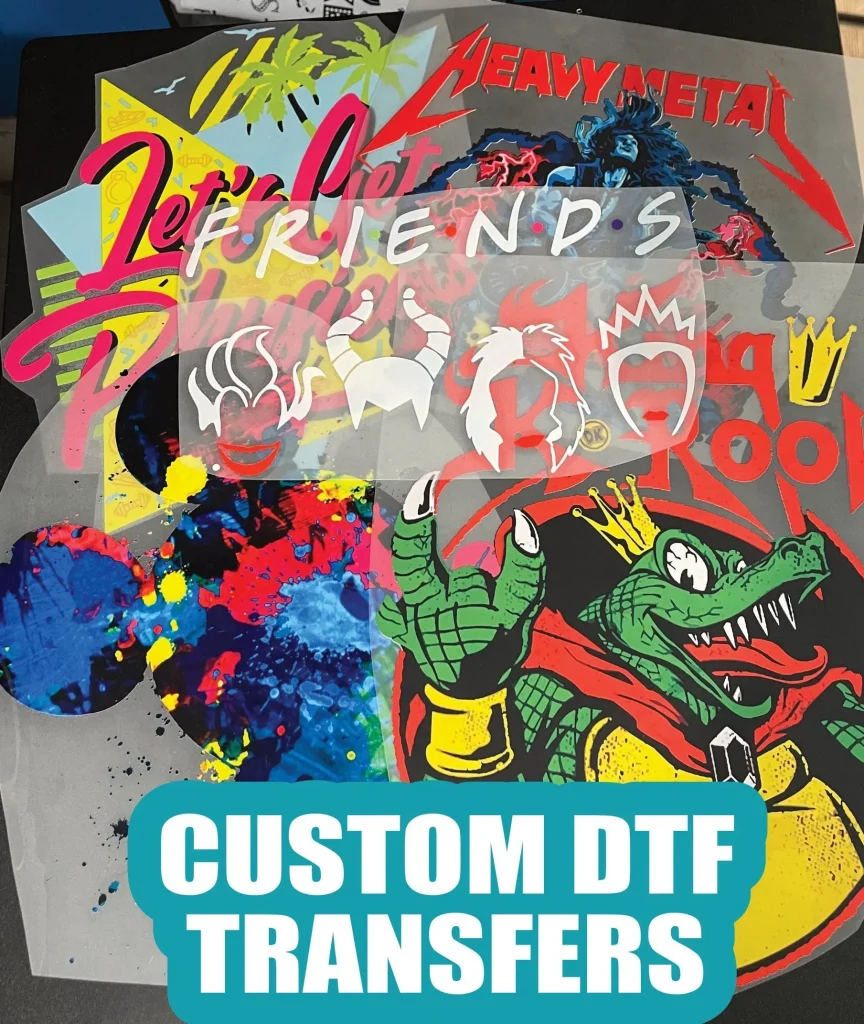

DTF transfers, or Direct-to-Film transfers, have revolutionized the custom apparel industry by providing an exceptional way to print vibrant designs onto various fabrics. Renowned for their versatility and quality, these transfers are ideal for anyone looking to enhance their creative projects. Choosing the right DTF transfers can significantly impact the final product, ensuring durability while delivering eye-catching visuals. In this guide, we will explore how to choose DTF transfers that best suit your needs, including an overview of the best DTF transfers available on the market today. From understanding DTF transfer types to examining the nuances of DTF printing, we’ll cover all you need to know for successful apparel transfers.

Direct-to-Film printing, often referred to as DTF printing, is a modern technique that simplifies the creation of custom designs on textiles. This innovative method allows for various transfer options, offering both simplicity and creativity for fabric decoration. By exploring different types of DTF transfers, including standard and specialty variations, you can achieve personalized apparel that stands out. Learning how to choose the best DTF transfers ensures that your printing projects are not only visually stunning but also durable and well-suited for your specific fabric needs. Embrace the world of apparel transfers with confidence as we break down the essential factors for your project.

Choosing the Best DTF Transfers for Your Project Needs

When it comes to selecting DTF transfers, it is crucial to match the transfer type with the specific needs of your project. The best DTF transfers will depend on the fabric you’re using, the complexity of your design, and the intended use of the apparel. For instance, standard DTF transfers are an excellent choice for straightforward designs, as they work effectively on various fabrics like cotton and polyester, ensuring that your print is both vibrant and durable.

In contrast, if your project calls for something a bit more unique, such as a glitter finish or metallic effects, you might want to explore specialty transfers. These options not only enhance the visual appeal but also allow for greater creativity in your designs. Keep in mind, however, that specialty transfers may require more careful application techniques, so understanding their specific requirements is essential to achieving the best results.

Exploring Different Types of DTF Transfers

DTF transfers are categorized mainly into standard and specialty types, and knowing the distinctions can streamline your decision-making process. Standard DTF transfers are ideal for designs that need to maintain color integrity and clarity across different types of apparel. They are particularly advantageous for bulk orders where uniformity is key, such as team uniforms or promotional apparel.

On the other hand, specialty transfers, such as those with glitter or metallic finishes, can be used to create eye-catching designs that stand out. However, these transfers not only require careful attention to application settings but also may have limitations in terms of the types of fabrics they adhere to. Always assess your project requirements to choose the type of DTF transfer that will work best.

Ensuring Material Compatibility with DTF Transfers

Compatibility between DTF transfers and fabric type is a key factor in achieving successful results. Cotton is typically the most forgiving fabric, allowing both standard and many specialty transfers to adhere well with excellent durability. Polyester and blends can be a bit trickier; some transfers may not adhere properly or could potentially damage the fabric if not carefully chosen.

To avoid complications, always ensure that the DTF transfers you select are designed for the specific material of your project. Researching manufacturers and their recommended fabric types can provide clarity and help you avoid pitfalls during the application process. This proactive approach significantly increases the likelihood of your designs not just looking great but also lasting longer.

Evaluating Print Quality in DTF Transfers

The resolution and print quality of DTF transfers can greatly impact the overall appearance and longevity of your designs. High-quality DTF transfers are capable of producing prints with sharp lines and vibrant colors, avoiding issues like bleeding or fading over time. Many brands offer different levels of print resolution, so it is worth spending time reviewing their offerings and examining customer feedback.

Before making a purchase, consider requesting samples from your preferred suppliers. This allows you to examine the print quality firsthand and gauge how well the transfer holds up in terms of clarity and brightness. Ultimately, investing in quality DTF transfers not only enhances the visual aspect of your apparel but ensures that your designs will stand the test of time, making them a smart choice for any project.

Understanding the DTF Application Process

The application process for DTF transfers can vary widely based on the transfer type and the fabric it is being applied to. Each transfer requires specific heat press settings—including temperature, pressure, and time—which you must adhere to in order to achieve an optimal bond. It is essential to consult the manufacturer’s guidelines for these settings to ensure a successful transfer.

Moreover, some designs may necessitate pre-pressing the fabric or special post-application care to maintain adhesion and appearance over time. When done correctly, an effective application results in a smooth feel and vibrant print that is resistant to washing and wearing. By mastering the application techniques, you can assure your DTF projects come out precisely as envisioned.

Tips for Selecting the Best DTF Printing Solutions

When it comes to DTF printing solutions, it’s important to consider not just the transfers themselves, but also the overall printing process. Look for suppliers that offer complete solutions including printers, inks, and transfer films that are compatible with your design needs. This holistic approach ensures all components work well together, optimizing the output quality of your printed designs.

Additionally, customer service and support from your chosen supplier can greatly enhance your experience. Having access to knowledgeable representatives who can help troubleshoot any issues or provide guidance on application techniques will ensure your projects go smoothly. Always research and choose a supplier who prioritizes quality and customer satisfaction in their offerings.

Frequently Asked Questions

How do I choose the best DTF transfers for my apparel projects?

Choosing the best DTF transfers involves considering fabric compatibility, print quality, and the specific types of DTF transfers available. Start by assessing the material of your garments; standard DTF transfers work well on cotton and polyester, while specialty transfers can add unique effects. Also, look for reputable manufacturers known for high-resolution printing.

What are the different types of DTF transfers available?

DTF transfers are primarily categorized into standard and specialty types. Standard DTF transfers are suited for various fabrics and offer durability, making them ideal for t-shirts and hoodies. Specialty DTF transfers include options like glitter and metallic finishes, which allow for creative designs but may require different application methods.

What factors should I consider for DTF printing on different fabrics?

When engaging in DTF printing, it’s crucial to consider fabric compatibility. For example, cotton works well with most DTF transfers, while polyester may not adhere as effectively. Always check if your chosen DTF transfers are designed for the fabric to ensure optimal adhesion and longevity.

How can I assess the print quality of DTF transfers before purchasing?

To assess the print quality of DTF transfers, request samples from manufacturers to review their resolution and color vibrancy. High-quality DTF transfers should maintain sharp lines and vivid colors, ensuring your designs stand out and last longer after repeated washes.

What is the application process for using DTF transfers effectively?

The application process for DTF transfers typically involves using a heat press and ensuring specific settings for temperature, pressure, and duration as per the manufacturer’s instructions. It’s essential to consider pre-pressing techniques and post-application care to achieve a durable and smooth finish.

Can I use DTF transfers on all types of apparel?

DTF transfers are versatile but not universally applicable to all apparel types. Standard DTF transfers are effective on cotton, polyester, and blends, while specialty DTF transfers may require specific fabrics for optimal results. Always verify compatibility with your clothing to ensure successful application.

| Key Point | Details |

|---|---|

| Types of DTF Transfers | Includes Standard DTF Transfers and Specialty Transfers, suitable for various designs and applications. |

| Standard DTF Transfers | Ideal for common fabrics like cotton, polyester, and blended fabrics; offers durability for basic designs. |

| Specialty Transfers | Unique options such as glitter and metallic designs that require special application techniques. |

| Material Compatibility | Ensure DTF transfers are compatible with your fabric to avoid issues; cotton works well with both standard and specialty transfers. |

| Print Quality | Look for high-resolution prints and reputable manufacturers to ensure sharpness and vibrancy. |

| Application Process | Adhere to specific heat press settings and application techniques to achieve optimal durability and feel. |

Summary

DTF Transfers are an exceptional choice for anyone looking to customize apparel with high-quality designs. When selecting the right DTF transfer for your projects, it’s essential to consider the type of transfer, fabric compatibility, print quality, and application process. By understanding the differences between standard and specialty transfers, along with ensuring the ideal material match and adherence techniques, you can achieve vibrant and durable designs that showcase your creative vision flawlessly. Investing the time to choose wisely will enhance the end product, making every piece a testament to quality craftsmanship.