In the ever-evolving landscape of custom printing, **DTF transfers** (Direct to Film transfers) are making headlines for their innovative approach to textile decoration. This cutting-edge technology enables vibrant designs and intricate patterns that were once challenging to achieve using traditional methods. As the demand for high-quality custom prints grows, understanding DTF printing becomes crucial for businesses looking to elevate their offerings. With best practices for DTF transfers, including eco-friendly options, this process is not just about aesthetics; it’s also about sustainability and efficiency in the DTF transfer market. Discover the secrets behind successful DTF printing as we delve deeper into this transformative technique.

Direct to Film technology, often referred to casually as DTF printing, represents a new frontier in the printing industry. This innovation simplifies the application of complex designs onto fabrics, providing creators with the versatility to explore their artistic visions without the limitations of traditional textile methods. With many businesses now recognizing the potential of DTF, the market for such transfers continues to expand, driven by both creative possibilities and environmental considerations. The focus on eco-friendly DTF transfers also highlights a growing trend among consumers seeking sustainable printing solutions. In this article, we will explore efficient strategies and vital information that can help businesses thrive in this exciting sector.

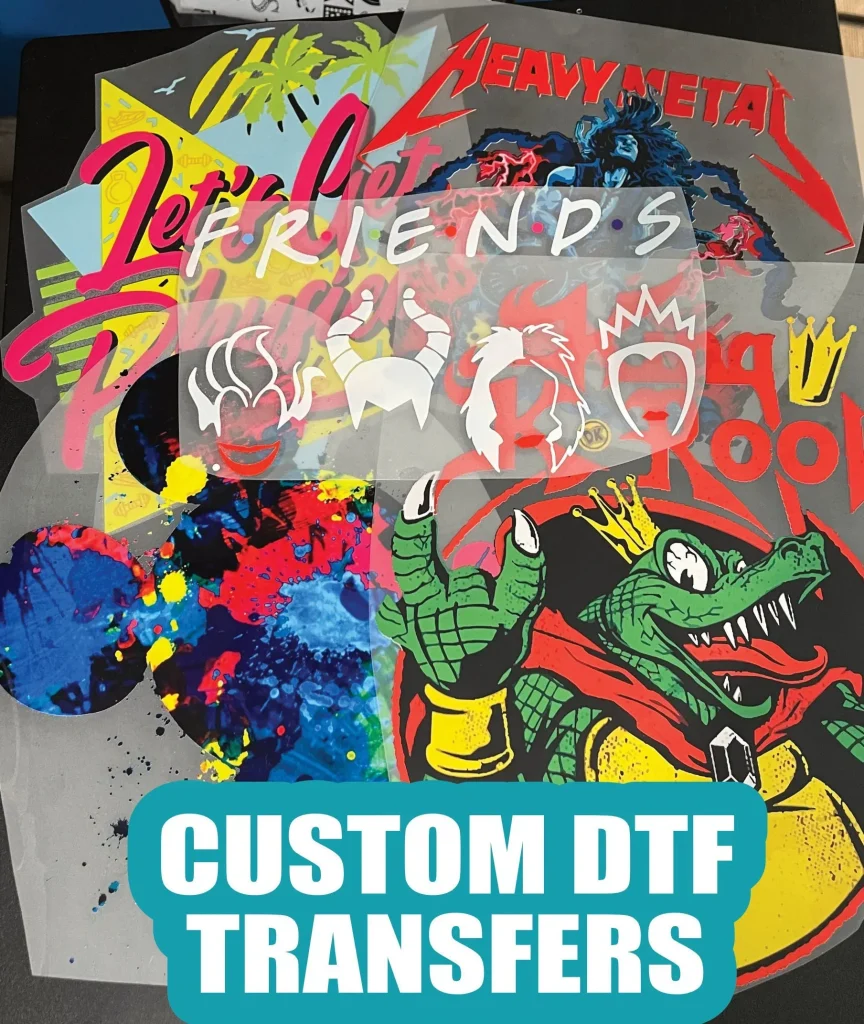

Introduction to DTF Transfers

DTF transfers, short for Direct to Film transfers, represent a remarkable leap in the realm of custom textile printing. Unlike traditional methods that rely heavily on screens and excessive setup, DTF technology simplifies the process by allowing intricate designs to be printed directly onto a film. This film can then be transferred onto a variety of fabric types, significantly broadening the creative horizons for designers and printers alike. DTF transfers are particularly renowned for their vibrant color reproduction and durability, making them a go-to choice for many apparel businesses.

The emerging popularity of DTF transfers can be attributed to the technology’s user-friendly operation. More than ever, entrepreneurs and small business owners are turning to DTF printing because it eliminates many of the complexities associated with traditional textile printing techniques. This has not only fueled creativity among designers but has also established a rapidly growing market segment dedicated to DTF transfers, demonstrating a strong alignment with consumer demand for innovative, high-quality fabric products.

Advantages of DTF Printing Over Traditional Methods

One of the standout advantages of DTF printing is its ability to produce exceptionally high-quality prints that remain vibrant over time. Unlike screen printing, which struggles with fine details and complex imagery, DTF technology excels in capturing rich colors and intricate designs. This enhancement makes it ideal for printing detailed graphics and photos onto fabrics, thus attracting businesses that prioritize precision and artistry in their product offerings.

In addition, DTF transfers are favored for their versatility across various fabric types. Whether it be cotton, polyester, or blends, DTF prints adhere seamlessly, which can often be a challenge with traditional methods. This flexibility allows businesses to target diverse markets and cater to specific customer needs, further promoting the growth of DTF technology in the textile industry.

Essential Best Practices for DTF Success

Implementing best practices in DTF printing is crucial to achieving optimal results. One fundamental aspect is the careful selection of materials; the choice of fabrics significantly influences the quality of the final product. Fabrics such as 100% cotton or high-quality polyester tend to yield the best results, maximizing both the vibrancy and longevity of the prints. Additionally, using the correct DTF film and printer will ensure that the designs transfer flawlessly to the fabric.

Prepress preparation also plays a vital role in the success of DTF transfers. Factors such as humidity and temperature can greatly affect print quality. Maintaining a controlled environment helps mitigate issues like ink bleeding, which can compromise the clarity of the designs. As per insights from industry experts, prioritizing these preprinting protocols can dramatically elevate the outcomes of DTF printing tasks.

Eco-friendly Innovations in DTF Printing

As the push for sustainability rises across industries, the DTF transfer market is evolving to embrace eco-friendly practices. Companies are increasingly committed to reducing their environmental footprint by sourcing sustainable inks and materials for DTF transfers. This shift is not only beneficial for the planet but also aligns with the growing consumer preference for environmentally responsible products.

Manufacturers are now exploring alternatives such as water-based inks and recyclable films, which resonate with consumers looking for ethical purchasing options. By integrating these sustainable practices into their operations, businesses can improve their reputation and appeal to a wider audience, ensuring they meet the demands of today’s conscientious shoppers.

The Growing Market for DTF Transfers

The DTF transfer market has experienced impressive growth in recent years, largely attributed to the easier accessibility this technology provides for small businesses and entrepreneurs. The relatively low initial investment required to set up DTF printing operations has opened the door for many individuals to explore custom printing. This democratization of DTF technology is creating a diverse landscape filled with unique offerings, increasing the overall visibility of DTF transfers in the consumer market.

Moreover, the proliferation of starter kits and online resources has simplified the learning curve for newcomers to the industry. Those interested in DTF printing can quickly acquire the skills and knowledge necessary to produce quality products, further propelling growth within the transfer market. As more individuals and enterprises tap into the capabilities of DTF technology, the potential for innovation and creativity continues to expand.

Future Prospects of DTF Technology

Looking ahead, the future of DTF technology appears bright, with many predicting continued evolution and integration with other digital printing methods. This synergy could unlock exciting possibilities for customization and personalization in various sectors, including fashion, home decor, and promotional products. Industry insiders anticipate that as technology advances, DTF printing will provide even higher quality outputs and greater efficiency than before.

Staying informed about these trends will be crucial for businesses aiming to capitalize on the DTF printing revolution. By embracing the latest developments and continually adapting to market demands, stakeholders can ensure they remain competitive in a rapidly changing landscape. Keeping an ear to the ground regarding advancements in ink formulations, processes, and equipment will position them strongly for future success.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing intricate designs onto a special film which is then heat-pressed onto various fabrics. This technology allows for vibrant, high-quality prints with excellent durability, making it a popular choice for textile printing.

What are the best practices for DTF printing?

To achieve optimal results with DTF printing, select the right fabric, maintain proper humidity during the printing process, and ensure thorough post-transfer curing. These best practices enhance print quality, durability, and washability of DTF transfers.

How is the DTF transfer market growing and why is it accessible?

The DTF transfer market has seen significant growth due to lower startup costs and the availability of starter kits. More home-based entrepreneurs are entering the market, driven by the versatility and reliability of DTF technology in custom printing.

Are eco-friendly DTF transfers available?

Yes, there is a growing trend towards eco-friendly DTF transfers. Many manufacturers are developing sustainable inks and materials, responding to consumer demand for environmentally responsible printing practices while maintaining high-quality outputs.

What recent developments have occurred in DTF technology?

Recent advancements in DTF technology include improved ink formulations that offer brighter colors and better adhesion, as well as new equipment designs that enhance the overall DTF printing process for various users, from small businesses to larger manufacturers.

What should I consider when selecting materials for DTF transfers?

When selecting materials for DTF transfers, it’s important to choose fabrics like cotton and polyester that yield the best results. Additionally, selecting the right type of film and ensuring compatibility with your printer is essential for achieving high-quality prints.

| Key Point | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers blend traditional printing with modern technology, enabling vibrant and detailed prints. |

| Understanding DTF Transfers | Involves printing designs on film which are then heat-pressed onto fabrics, offering versatility over traditional methods. |

| Advantages of DTF Transfers | Produces high-quality, durable prints, excelling in complex images and vibrant colors. |

| Recent Developments | In 2024, advancements in inks and equipment have improved efficiency and quality in DTF printing. |

| Market Growth | Increased accessibility for small businesses and entrepreneurs due to lower startup costs. |

| Best Practices | Essential practices include choosing suitable materials, preparing the environment, and caring for transfers. |

| Sustainability Efforts | Growing demand for eco-friendly inks and materials in DTF printing. |

| Future Trends | Integration of DTF with digital printing is anticipated, enhancing customization options. |

Summary

DTF transfers are revolutionizing the world of custom textile printing, offering an advanced means to create high-quality, vibrant designs with remarkable durability. As this technology evolves, it presents exciting opportunities not just for established businesses but also for small entrepreneurs entering the market. By focusing on best practices and embracing sustainable trends, those involved in DTF transfers can enhance their offerings while meeting consumer demands for eco-friendly products. The future of DTF transfers looks promising, making it essential for businesses to stay informed and adaptable in this dynamic landscape.