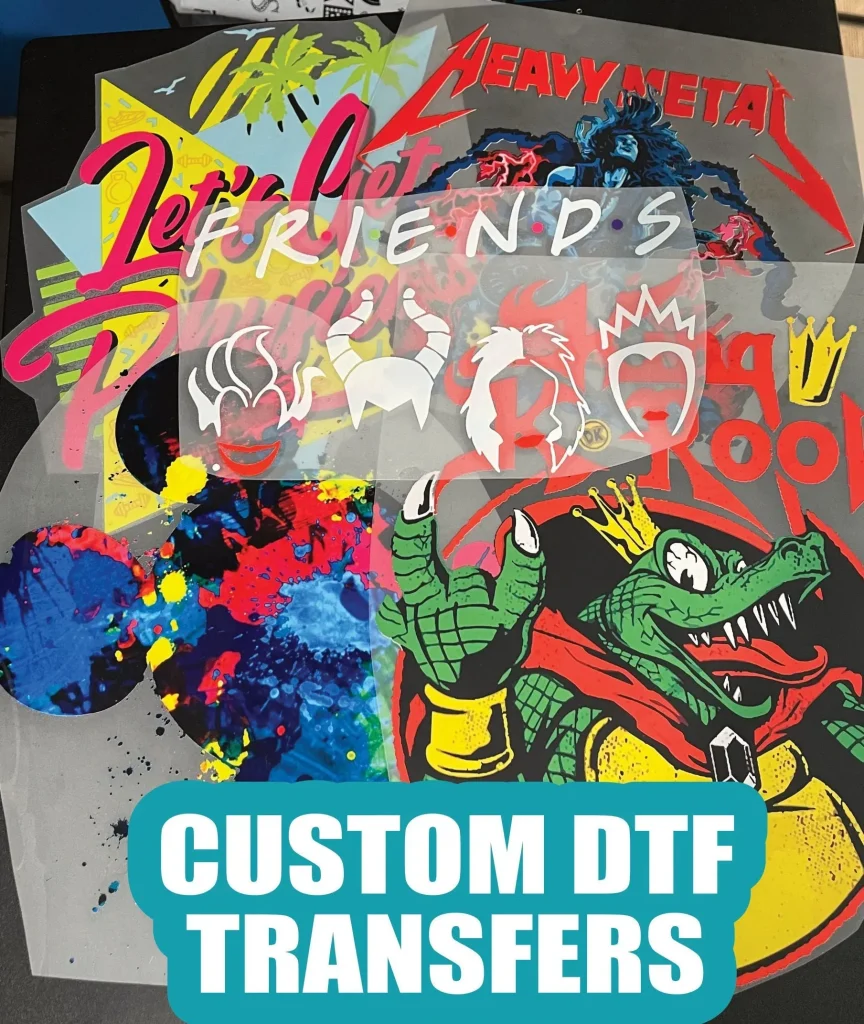

DTF transfers have revolutionized the world of apparel printing, combining creativity with technical precision to meet the evolving demands of fashion enthusiasts and businesses alike. Also known as Direct-to-Film printing, this cutting-edge technology allows for vibrant, high-resolution designs to be transferred onto garments quickly and efficiently. With the advantages of cost-effective printing methods, DTF transfers enable businesses to produce custom apparel that stands out in a saturated market. As we delve into the myriad DTF printing benefits, you’ll discover how this innovative approach not only enhances product quality but also streamlines the production process. Embracing DTF transfers in your apparel business can position you ahead of the competition, offering customers compelling designs that they’ll love to wear.

The application of Direct-to-Film printing techniques is reshaping the landscape of garment decoration, offering a modern solution to meet the needs of contemporary apparel makers. This apparel printing technology opens up a realm of possibilities for vibrant designs and intricate details that appeal to discerning consumers. As a versatile and innovative method, this approach reduces traditional barriers in the printing process, making it an ideal choice for businesses aiming to deliver outstanding custom apparel. The benefits of this relatively new printing style can greatly enhance production efficiency, allowing companies to remain agile in a dynamic fashion market. Adopting this method can potentially title your business as a leader in innovative and quality apparel options.

Understanding DTF Transfers: An Overview

DTF Transfers, or Direct-to-Film transfers, represent a groundbreaking advancement in apparel printing technology. This method allows vibrant and high-resolution images to be printed directly onto a special film, which can then be applied to fabric using heat. Unlike traditional methods, such as screen printing, DTF printing provides unparalleled flexibility, enabling businesses to produce intricate, colorful designs that stand out in today’s competitive market. With their ability to adhere to a wide variety of fabrics, DTF transfers open up opportunities for diverse custom apparel options.

As the apparel industry continues to adapt to changing consumer preferences, DTF transfers have emerged as a preferred choice for many businesses. The technology not only enhances print quality but also ensures durability and longevity, meeting the expectations of quality-conscious consumers. With low production costs and quick turnaround times, understanding DTF transfers is crucial for any apparel business aiming to thrive in this digital age.

Advantages of DTF Printing for Apparel Businesses

The advantages of DTF printing are numerous, particularly in the realm of custom apparel production. One of the most significant benefits is the superior quality of the prints. DTF technology captures rich colors and intricate details, making it perfect for complex graphics and designs. This capability means businesses can offer customers unique, personalized clothing without compromising quality. As noted in various industry reports, the exceptional adherence of DTF prints to different fabric types ensures that these high-quality results don’t fade or wash out over time.

Moreover, the versatility of DTF transfers extends beyond just fabric types; businesses can easily cater to different styles and trends in the market. This flexibility not only broadens product offerings but also allows quick adaptations to new fashion demands. In an industry where customization and quality are paramount, leveraging the advantages of DTF printing can significantly enhance a brand’s reputation and customer satisfaction.

DTF Transfers: A Cost-Effective Solution for Custom Printing

Cost is always a critical factor in the apparel industry, especially for small to medium-sized businesses. DTF transfers provide a cost-effective printing alternative to traditional methods like screen printing. Since DTF technology reduces setup times, labor costs, and material waste, businesses can save money on short runs and bulk orders alike. This economic efficiency enables apparel companies to remain competitive while maintaining healthy profit margins.

Additionally, the lower production costs associated with DTF transfers allow for more accessible pricing strategies, which can attract a broader customer base. It empowers businesses to fulfill numerous custom orders without sacrificing quality or incurring excessive overhead expenses. In an industry increasingly driven by demand for personalized products, the cost-effectiveness of DTF printing is a game-changer.

Embracing the Simplicity of DTF Printing Processes

One of the most appealing aspects of DTF transfers is the simplicity of the printing process itself. Unlike traditional printing methods that require complicated machinery setups and extensive manual labor, DTF printing streamlines operations, allowing for a smoother workflow. The process involves printing directly onto a film, which can then be easily transferred onto garments with a heat press. This simplicity reduces bottlenecks in production, making it easier for businesses to fulfill orders quickly.

Furthermore, the straightforward nature of DTF printing means that businesses of all sizes, even those without extensive experience in apparel printing technology, can easily adopt this method. The reduction in complexity not only speeds up production times but also enhances efficiency within the business, promoting faster growth and customer satisfaction in a fast-paced market.

The Importance of Rapid Turnaround Times in Apparel Printing

In the competitive apparel market, the ability to deliver rapid turnaround times is a significant advantage. DTF transfers excel in this area, enabling businesses to respond quickly to trends and consumer demands. With advancements in large-format DTF printers, companies can produce high-volume outputs in short time frames, which is vital for maintaining customer loyalty and satisfaction.

On-demand printing capability also allows businesses to minimize inventory costs and reduce waste, which is especially important for environmentally-conscious consumers. The agility afforded by DTF technology not only boosts a brand’s reputation but also enhances operational efficiency, allowing for quick adjustments in response to market changes.

Innovative Business Models Leveraging DTF Technology

The rise of DTF transfers has sparked innovation in various business models within the apparel industry. Companies like Snuggle DTF are leading the way by creating platforms that simplify the purchasing of DTF services. These specialized online marketplaces provide instant access to production resources, allowing apparel businesses to launch customized merchandise rapidly. Such platforms are designed to cater specifically to the needs of printers and brand owners, providing innovative, scalable solutions.

This shift toward digital solutions not only enhances the customer experience but also promotes efficiency within the apparel supply chain. As more businesses recognize the potential of DTF technology for expanding their product offerings, the demand for digital and DTF services will likely continue to grow, making it a pivotal area for future development in the apparel domain.

Frequently Asked Questions

What are the main advantages of using DTF transfers in apparel printing?

DTF transfers offer high-quality prints with vibrant colors and intricate details, making them perfect for custom apparel. They are versatile across various fabric types, cost-effective for both short runs and large orders, simplify the printing process, ensure rapid turnaround times, and allow for innovative business models.

How does Direct-to-Film (DTF) printing compare to traditional screen printing?

DTF printing surpasses traditional screen printing by providing a more efficient setup process, reduced waste, and versatility in fabric compatibility. This modern method allows for detailed designs to be printed quickly, making it a favorable choice for custom apparel businesses.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers are highly versatile and can be applied to numerous fabric types, including cotton, polyester, and blends. This capability enables businesses to cater to diverse market segments without needing extensive equipment modifications.

What makes DTF transfers a cost-effective solution for custom apparel?

DTF transfers reduce overhead costs by minimizing setup times, waste, and labor compared to traditional methods. This efficiency allows businesses to manage custom orders more profitably, making DTF printing an economical choice for both small and large production runs.

How do DTF transfers facilitate rapid order fulfillment?

Thanks to the simplified printing process and advanced DTF technology, businesses can transition from design to final product quickly. This capability for fast production helps meet customer demands and enhances satisfaction, which is essential in the competitive apparel market.

What recent developments are impacting the DTF printing industry?

Recent developments include investments in high-capacity DTF printers and the launch of web-to-print platforms by companies like Snuggle DTF. These advancements streamline the customer purchasing experience and improve order fulfillment, reflecting a growing trend in the DTF printing landscape.

| Feature | Description |

|---|---|

| High-Quality Transfers | Produces intricate designs with vibrant colors that enhance overall garment appeal. |

| Versatility Across Fabric Types | Compatible with a variety of fabrics including cotton and polyester, allowing for diverse product lines. |

| Cost-Effectiveness for Custom Orders | Reduces setup times and waste, making it economical for both short runs and large orders. |

| Simplified Printing Process | Streamlines workflow with minimal setup time compared to traditional methods. |

| Rapid Turnaround Times | Allows for quick production of high volumes, satisfying consumer demand efficiently. |

| Innovative Business Models | Emergence of specialized platforms simplifies purchase and access to DTF transfers. |

| Recent Developments in DTF Technology | Ongoing advancements enhance production capabilities and integration within e-commerce. |

Summary

DTF Transfers revolutionize the apparel business by providing high-quality, cost-effective, and versatile printing options that cater to diverse fabric types. As a state-of-the-art printing method, DTF technology allows businesses to maintain competitive advantage in a rapidly evolving market. With its exceptional print quality, simplified processes, and ability to meet increasing consumer demand, adopting DTF Transfers can significantly enhance product offerings and operational efficiency. As the apparel industry continues to embrace innovations, leveraging the benefits of DTF transfers is vital for sustainable growth, ensuring businesses not only meet but exceed customer expectations.