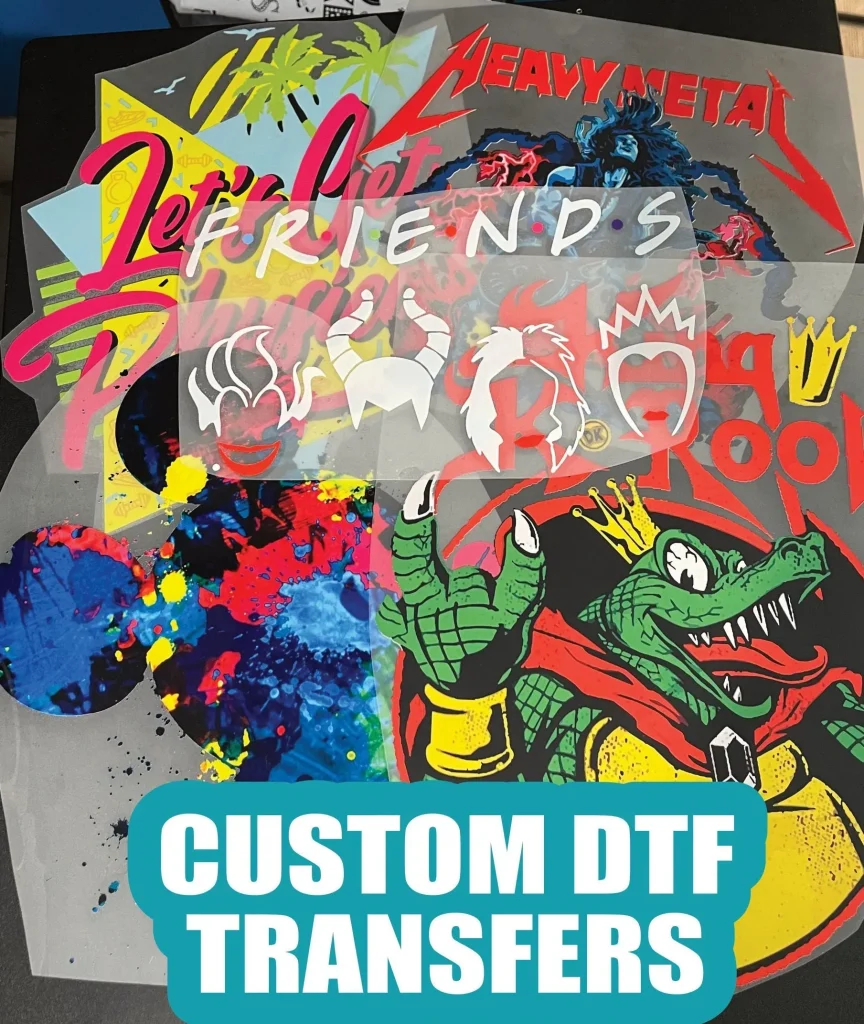

DTF transfers, or Direct-to-Film transfers, represent a significant advancement in the textile printing industry, revolutionizing how designs are applied to fabrics. This innovative DTF technology not only ensures vibrant and long-lasting prints but also supports sustainable printing practices, making it a preferred choice for eco-conscious creators. For both small business owners and passionate hobbyists, mastering the art of design for DTF can drastically enhance the outcome of their projects. In this article, we will delve into the intricacies of DTF printing, exploring its benefits and offering tips to maximize your design potential. Join us as we unveil the secrets behind creating stunning visuals that make a lasting impact.

The realm of textile decoration has been transformed by Direct-to-Film transfer methods, providing creatives with a versatile medium for transferring their artistic visions onto fabric. Often referred to as DTF printing, this approach utilizes specialized films and inks to achieve exceptional clarity and color vibrancy that traditional methods may struggle to provide. With an emphasis on sustainable printing practices, this technique not only caters to evolving market demands but also reduces waste significantly. By understanding the principles behind designing for DTF, individuals can fully leverage this method’s capabilities to produce unique and high-quality prints. As we explore these alternatives to conventional textile decoration, you’ll discover the exciting potential of this advanced printing technology.

Understanding DTF Technology

Direct-to-Film (DTF) technology represents a significant leap forward in the textile printing industry. This innovative printing method utilizes a film as a medium for transferring intricate designs onto various fabrics. Unlike other printing methods, DTF transfer allows designers to create high-quality prints with enhanced color fidelity while minimizing the environmental impact associated with traditional textile printing. By leveraging advanced digital printing techniques, DTF has gained traction for its ability to produce detailed prints quickly, catering to today’s fast-paced production demands.

Moreover, DTF technology’s adaptability is one of its strongest features. It is compatible with various types of fabrics, including cotton, polyester, and blends, making it a favorite amongst designers who seek versatility in their work. The advanced ink used in DTF printing not only adheres well to diverse surfaces but also withstands multiple washes without fading, ensuring longevity in product quality. As the trend towards eco-friendly processes grows, DTF emerges as a front-runner in sustainable textile printing.

Benefits of Designing for DTF Transfers

Designing for DTF transfers comes with numerous advantages that creators should recognize. First and foremost is the vibrant color output; DTF printing technology uses high-quality inks that deliver vivid colors and precise details. This capability allows designers to explore bold and creative designs without the fear of losing color accuracy in the final product. With DTF transfers, even the most intricate patterns can be reproduced with clarity, setting a new standard in the quality of custom apparel.

Additionally, the ease of use associated with DTF transfers makes it an appealing option for both new and experienced designers. Many DTF printers have been optimized to ensure a user-friendly experience, allowing even those without extensive technical skills to create professional-quality designs. The print-on-demand nature of DTF also aligns with contemporary market trends that favor personalization, making it easier for businesses to cater specifically to customer preferences without incurring significant upfront costs.

Best Practices for DTF Transfer Designs

To produce impeccable DTF transfer designs, several best practices should be employed. First, focusing on high-resolution images is crucial—designers should always start with a minimum of 300 DPI. High-quality images not only contribute to sharper prints but also enhance the overall visual appeal of the finished product. Similarly, understanding and utilizing color profiles—such as CMYK—will ensure that the colors displayed on screens closely match those printed onto fabric.

Moreover, incorporating vector art in designs is recommended to avoid pixelation when scaling. Vector graphics provide clean edges and can be easily manipulated, making them ideal for printing via DTF technology. Experimenting with textures and gradients can also elevate the design, allowing for unique and visually captivating artwork that stands out in the competitive market. Ultimately, adherence to these best practices can lead to striking results that showcase the true potential of DTF printing.

Real-World Applications for DTF Transfers

The practical applications of DTF transfers extend far beyond simple garment customization. In the realm of fashion, DTF technology is increasingly utilized to create exclusive and limited-edition pieces, empowering designers to innovate without extensive financial risks. By facilitating low-volume runs without the need for hefty setup costs associated with traditional printing, DTF helps make unique fashion statements accessible to a wider audience.

Additionally, DTF transfers significantly benefit businesses in promotional product creation. Companies can leverage the technology to develop eye-catching merchandise, such as branded apparel, tote bags, and hats that resonate with their target audience. This not only enhances brand visibility but also offers customers high-quality products that celebrate their interests or affiliations. The versatility of DTF transfers means that opportunities abound across various sectors, from retail to corporate branding.

Sustainability in DTF Printing

In today’s eco-conscious world, sustainability is a major consideration for artists and businesses alike. DTF printing stands out as an environmentally friendly alternative compared to traditional fabric printing methods. By minimizing ink waste and adopting energy-efficient practices, DTF technology promotes a more sustainable operation, ultimately reducing the carbon footprint associated with textile printing. This shift towards greener processes is not merely a trend but a growing necessity in the industry.

Furthermore, sustainable printing practices play a pivotal role in attracting environmentally-conscious consumers. By opting for DTF printing, designers can create eco-friendly products that align with the values of today’s shoppers, who often prioritize sustainability in their purchasing decisions. As more businesses recognize the importance of responsible production, the adoption of DTF transfers could significantly affect the industry’s move towards comprehensive sustainability.

The Future of DTF Printing

As DTF technology continues to evolve, its potential for innovation in textile printing appears limitless. Advances in digital printing technology and increased capabilities are driving the DTF market forward, making it a go-to option for designers and businesses looking to capitalize on personalization trends. This constant development ensures that DTF printing remains relevant and competitive, as it adapts to the ever-changing demands of the fashion and design landscape.

Keeping up with the latest trends and technological advancements will be crucial for anyone involved in DTF printing. Networking with other professionals, attending industry trade shows, and following industry news are all effective ways to stay informed. By remaining proactive and adaptable to emerging practices, designers can harness the full potential of DTF technology to create stunning, market-ready products that reflect contemporary consumer preferences.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is an innovative method that transfers designs onto various fabrics using specialized inks on a film. The process involves printing your design on a special film, followed by applying it to fabric using heat and pressure, resulting in vibrant and detailed color renditions.

What are the key benefits of using DTF transfers in textile printing?

The key benefits of DTF transfers include vibrant color quality, minimal ink waste, versatility in fabric compatibility, and eco-friendly practices. This technology helps businesses adopt sustainable printing methods while producing high-quality designs that are suitable for various materials.

How can I design effectively for DTF transfers?

To design effectively for DTF transfers, start with high-resolution images (at least 300 DPI), use graphic design software that supports vector graphics, and ensure you work in the CMYK color profile for better print accuracy. Incorporating vector art and experimenting with textures will also enhance your prints.

What materials can DTF transfers be applied to?

DTF transfers can be applied to a wide array of materials, including cotton, polyester, leather, and some synthetic fabrics. This versatility allows designers and creators to explore various options in their projects and cater to different customer preferences.

Is DTF technology really eco-friendly?

Yes, DTF technology promotes eco-friendly practices by minimizing ink waste and allowing heat recycling during the transfer process. As companies focus on sustainable printing, DTF presents an attractive solution for reducing environmental impact in textile production.

How do I stay updated on the latest trends in DTF printing?

To stay updated on trends in DTF printing, follow industry news sites like TechBullion and Creative Bloq, engage with online communities dedicated to DTF printing, and attend trade shows that highlight advancements in printing technology and techniques.

| Key Points | Details |

|---|---|

| Introduction | DTF transfer technology simplifies the process of turning ideas into visual products, enhancing color vibrancy and supporting sustainable practices. |

| What is DTF Printing? | A method that transfers designs onto fabric using specialized inks and films, enabling high-quality prints with minimal waste. |

| Key Benefits | 1. Vibrant Colors 2. Eco-Friendly Practices 3. Ease of Use 4. Diverse Material Compatibility |

| Designing for DTF Transfers: Best Practices | 1. Use High-Resolution Images 2. Choose the Right Software 3. Understand Color Profiles 4. Incorporate Vector Art 5. Experiment with Texture |

| Real-World Applications | Customized merchandise, fashion industry, promotional products. |

| Staying Updated with DTF Innovations | 1. Follow Industry News 2. Network with Other Creators 3. Attend Trade Shows |

Summary

DTF Transfers have revolutionized the world of textile printing by providing an innovative way to produce vibrant and eco-friendly designs. Utilizing Direct-to-Film technology not only enhances the quality of prints but also aligns with sustainable practices that resonate with today’s market demands. As artists and businesses alike explore this versatile printing method, the ability to transform creative ideas into stunning visuals has become exceptionally accessible. Embracing DTF Transfers not only sets one apart in a competitive landscape but also opens up endless possibilities for personalized and impactful designs.