DTF transfers, or Direct to Film transfers, are revolutionizing the way artists and crafters create vibrant designs on fabric. This innovative printing technique allows for high-quality graphics that not only look stunning but also withstand the test of time, making them perfect for both personal projects and commercial applications. In this guide, we will explore how to create DTF designs, understand the DTF printing process, and discover best practices for DTF transfers that ensure your designs pop. From essential DTF transfer tips to detailed steps for successful implementation, you’ll learn everything needed to harness this remarkable technology. Get ready to unleash your creativity and produce eye-catching textiles that leave a lasting impression!

The world of fabric design is embracing advanced methods, with Direct to Film transfer techniques leading the charge. By utilizing specialized film and high-resolution graphics, this process enables artists to transfer intricate designs onto a variety of materials seamlessly. This approach not only enhances the vibrancy and durability of prints but also opens up new avenues for customization in fashion and other textile applications. As we dive into the specifics of creating, printing, and applying these remarkable designs, you’ll discover essential tips and tricks to maximize your results. Whether you’re just starting out or looking to refine your skills, understanding DTF transfers will elevate your creative projects to new heights.

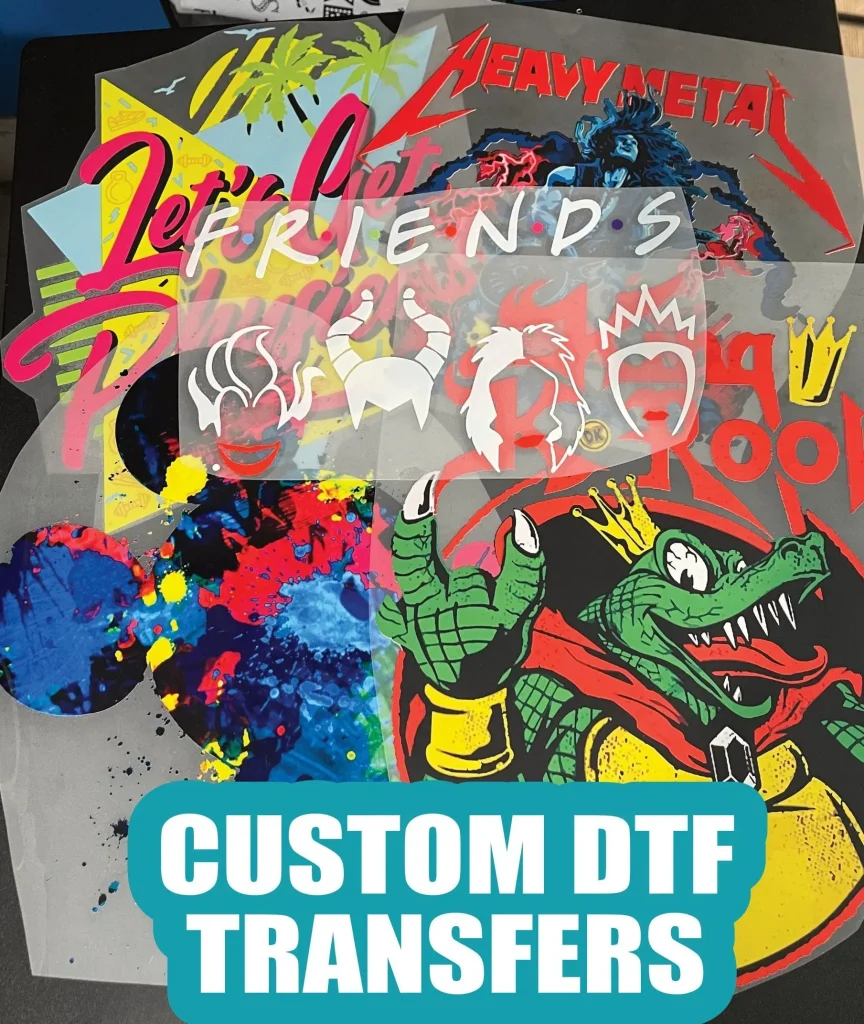

Understanding the Importance of DTF Transfers

DTF transfers represent a significant innovation in the printing industry, blending convenience with artistic expression. This method allows crafters and businesses to produce eye-catching designs quickly and efficiently. Unlike traditional screen printing or heat transfer vinyl, DTF offers a broader range of fabric compatibility, making it an ideal choice for diverse projects. With its ability to yield excellent results on cotton, polyester, and blended fabrics, DTF transfers cater to various demands across fashion, sports apparel, and promotional merchandise.

Moreover, DTF transfers provide an impressive level of detail and vibrancy that is often unattainable with other methods. Users can create intricate designs and vibrant color gradients that stand out and capture attention. This makes DTF a preferred choice for custom apparel and unique designs, allowing creators to express their style and brand effectively.

Exploring the DTF Printing Process

The DTF printing process is a multi-step approach that ensures designs are transferred with precision and durability. Initially, it involves creating high-resolution artworks using software tools such as Adobe Illustrator or Photoshop. Once the graphics are perfected, they are printed onto a special DTF film using a compatible printer and ink. The added layer of powder adhesive is a game-changer, as it helps to bond the ink effectively to the fabric when heat is applied.

Following the printing, the application of heat through a press activates the adhesive, allowing the design to adhere seamlessly to the garment. Each stage requires attention to detail, especially in ensuring that the print settings and temperature are optimized for the best results. Understanding the nuances of the DTF printing process can significantly impact the quality of the final product.

Steps to Create Stunning DTF Designs

Creating stunning DTF designs starts with a solid foundation of graphic design principles and software proficiency. Designers must consider factors such as color contrast, resolution, and artistic elements when crafting their work. A meticulous approach to each stage, from design creation to film preparation, is crucial for achieving vibrant and professional-looking results.

Additionally, it’s essential to conduct test runs on scrap materials. This practice helps identify potential issues related to ink adhesion and color compatibility. Adequate preparation directly affects the final design’s quality and can make a significant difference in the aesthetic appeal of the printed garment.

Best Practices for DTF Transfer Success

To achieve the best results with DTF transfers, it’s vital to select high-quality materials, right from the film to the inks. Using specially formulated DTF inks can enhance color vibrancy and adhesion quality. Furthermore, maintaining equipment regularly and calibrating printer settings for each specific project can vastly improve transfer outcomes.

Another pivotal best practice includes following recommended guidelines for the temperature and time settings during the heat pressing phase. Each fabric type may respond differently to heat, so adjusting these parameters can safeguard both the design and the garment. Keeping a consistent workflow will ensure that each transfer maintains high standards.

Essential Tips for Creating Vibrant DTF Designs

When embarking on the journey to create vibrant DTF designs, it’s essential to choose colors that not only pop but also complement the fabric. Testing color palettes on similar materials before final application can help guarantee that the hues will present well once printed. Vibrancy cannot only be achieved through color selection but also through the level of detail in the artwork—higher resolutions ultimately yield sharper images.

It is also advisable to continually assess industry trends and design styles within the DTF community. Staying updated with popular motifs and themes can inspire new creations and keep your designs fresh and appealing to various audiences.

Maximizing Design Durability with DTF Transfers

Maximizing the durability of DTF transfers comes down to several key practices aimed at reinforcing the design’s resilience against wear and washing. Firstly, a secondary heat press can be instrumental in securing the transfer after the initial application. By applying heat once more, especially on fabrics that may experience more stretching or movement, the adhesion becomes reinforced.

Another consideration for promoting longevity is the choice of washing instructions provided to customers. Encouraging gentle wash cycles and air drying instead of tumble drying can significantly extend the life of the printed design, ensuring that it remains vivid and intact for many wears.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process involves printing designs onto a special film using DTF printers equipped with unique inks. Once printed, a powder adhesive is coated onto the wet ink, which is then cured with heat. This prepares the design for transfer onto fabric, where the adhesive bonds the ink to the material when heat pressed. This method is ideal for vibrant, durable prints on various fabrics.

How do I create DTF designs that stand out?

To create standout DTF designs, focus on high-contrast color palettes and use high-resolution graphics (at least 300 DPI). Utilize graphic design software such as Adobe Illustrator or Photoshop to create your artwork. Conduct test prints on scrap fabric to ensure the design’s quality and adhesion before applying it to the final garment.

What are some best practices for DTF transfers?

Best practices for DTF transfers include using quality graphic assets, temperature control on the heat press, and ensuring adhesive is properly cured. Always test print on scrap materials to gauge durability and accuracy. Additionally, keep a cover sheet over your designs during pressing to protect both the artwork and the heat press surface.

What are essential DTF transfer tips for beginners?

For beginners, essential DTF transfer tips include selecting vibrant colors that pop, using high-quality graphics to prevent pixelation, and familiarizing yourself with your DTF printer settings. Also, practice the entire process on test fabrics to refine your technique before moving on to final products.

How can I ensure successful DTF transfer adhesion to fabric?

To ensure successful DTF transfer adhesion, apply the powder adhesive immediately after printing, and shake off any excess to avoid clumping. The curing step is crucial; make sure to use the right heat settings (typically around 320°F) during the heat press stage to activate the adhesive properly for optimal bonding.

How do I care for garments printed with DTF transfers?

To care for garments printed with DTF transfers, wash them inside out in cold water and avoid bleach. It’s recommended to tumble dry on a low setting or hang dry to preserve the vibrancy and durability of the print. Additionally, avoid ironing directly on the transfer; instead, iron the reverse side if necessary.

| Key Point | Description |

|---|---|

| Introduction to DTF Transfers | DTF transfers use a special film to apply designs onto fabrics, resulting in vibrant images that withstand washing. |

| Understanding the Process of DTF Transfer | Combines digital printing and heat transfer techniques for detailed designs. |

| Step-by-Step Guide | Covers design creation, printing, applying adhesive, curing, transferring, and finishing touches. |

| Tips for Stunning DTF Designs | Emphasizes color selection, quality graphics, testing, and staying updated on trends. |

| Conclusion | DTF transfers offer a rewarding combination of creativity and technical skill for durable fabric designs. |

Summary

DTF transfers have revolutionized the way designers create stunning fabric designs, combining innovation and artistry to deliver high-quality results. This process not only enables vibrant and durable prints but also opens up a world of creative possibilities on various textiles. By understanding the essential steps and implementing expert tips, anyone can create visually striking designs that stand the test of time. Optimistically, the future of fabric decoration is bright with DTF transfers, making it an exciting frontier for both amateurs and professionals alike.