DTF transfers, or Direct to Film transfers, have become a go-to method for those looking to create vibrant and durable designs on fabric. This innovative printing technique sets itself apart by enabling intricate designs with multiple colors, making it ideal for custom apparel and promotional items. As you embark on your creative journey, understanding how to create DTF designs is essential—this will allow you to leverage the best DTF transfer materials and techniques to achieve stunning results. In this guide, we will share valuable DTF design tips and outlines for the DTF transfer printing process, ensuring your projects reflect the highest quality. Whether you’re a seasoned designer or just beginning, mastering DTF transfers can elevate your crafting skills and enhance your artistic expressions.

Direct to Film printing, often referred to as DTF, is a revolutionary method gaining traction for its ability to produce high-quality designs on various fabrics. This process involves transferring detailed graphics through a unique film, setting the stage for impressive prints that last. For anyone interested in custom garment decoration or promotional items, exploring DTF techniques could be a game-changer. By learning how to create designs suitable for this method, as well as selecting the best materials, you pave the way for stunning and professional-grade apparel. Dive into the world of DTF solutions to unlock a realm of creativity and vibrant fashion possibilities.

The Basics of DTF Transfer Printing

DTF transfer printing stands out as a revolutionary method for applying designs onto apparel, primarily due to its ability to create vibrant colors and intricate shapes. This technique involves printing your design onto a special film, which then acts as a medium for transferring graphics onto various materials, including cotton and polyester. The process not only allows for high-definition imaging but also the flexibility to utilize intricate color variations, making it perfect for custom apparel projects that require detailed artwork.

Moreover, DTF transfers are a game-changer for small businesses looking to expand their product offerings. Unlike traditional printing methods that may be limited to specific fabrics or color constraints, DTF printing is versatile and can accommodate nearly any fabric blend. This adaptability means businesses can cater to a wider audience, providing personalized items that reflect individual styles and preferences.

Essential Materials for DTF Transfers

Selecting the best DTF transfer materials is one of the most critical steps to ensuring your designs come out perfectly. To begin, high-quality transfer film is essential; it serves as the foundation for your print and must possess strong adhesive properties to ensure durability and clarity. When shopping for transfer film, you should seek out reputable suppliers who offer products tested for optimal compatibility with DTF printers.

In addition to quality film, the choice of inks is also paramount. DTF-compatible inks are developed explicitly for this type of printing and are designed to produce vivid images that stand the test of time. Using the improper ink can lead to muted colors or excessive fading after washes. Thus, investing in high-quality inks can significantly enhance the durability of your projects and contribute to the overall success of your printing efforts.

Design Principles for Stunning DTF Projects

Mastering design principles is crucial when creating stunning DTF transfer designs. The foundation of every successful design lies in understanding color theory and composition. By choosing complementary colors and balancing design elements, your final product will be visually appealing and engaging. Simplifying your designs can also lead to better outcomes, as overly intricate graphics may become lost once transferred, especially if applied to fabric with a texture.

When using graphic design software to create your DTF designs, take advantage of tools and resources that help visualize how your colors will appear on various fabrics. This approach not only improves your skills but also prepares you to make appropriate adjustments before finalizing your artwork, ensuring that your creations maintain their vibrancy and effectiveness in any application.

Step-by-Step Guide to Preparing Your DTF Design

Preparing your DTF design is a meticulous process that significantly impacts the final result. Start by ensuring that your artwork has the correct resolution, ideally 300 DPI, to guarantee clear and sharp prints. In addition, select the proper file format, with PNG and vector files being the most common choices for DTF transfer printing. These formats preserve the quality and clarity necessary for effective printing, ensuring your designs translate beautifully onto fabric.

Another critical step in this process is mirroring your design before printing. This essential adjustment allows the image to be oriented correctly once it transfers to the fabric. Failing to do this can lead to frustrating mistakes where your design appears backward on the garment. Taking the time to prepare your design correctly will ultimately save you from potential pitfalls and enhance the quality of your finished product.

The Printing Process Explained

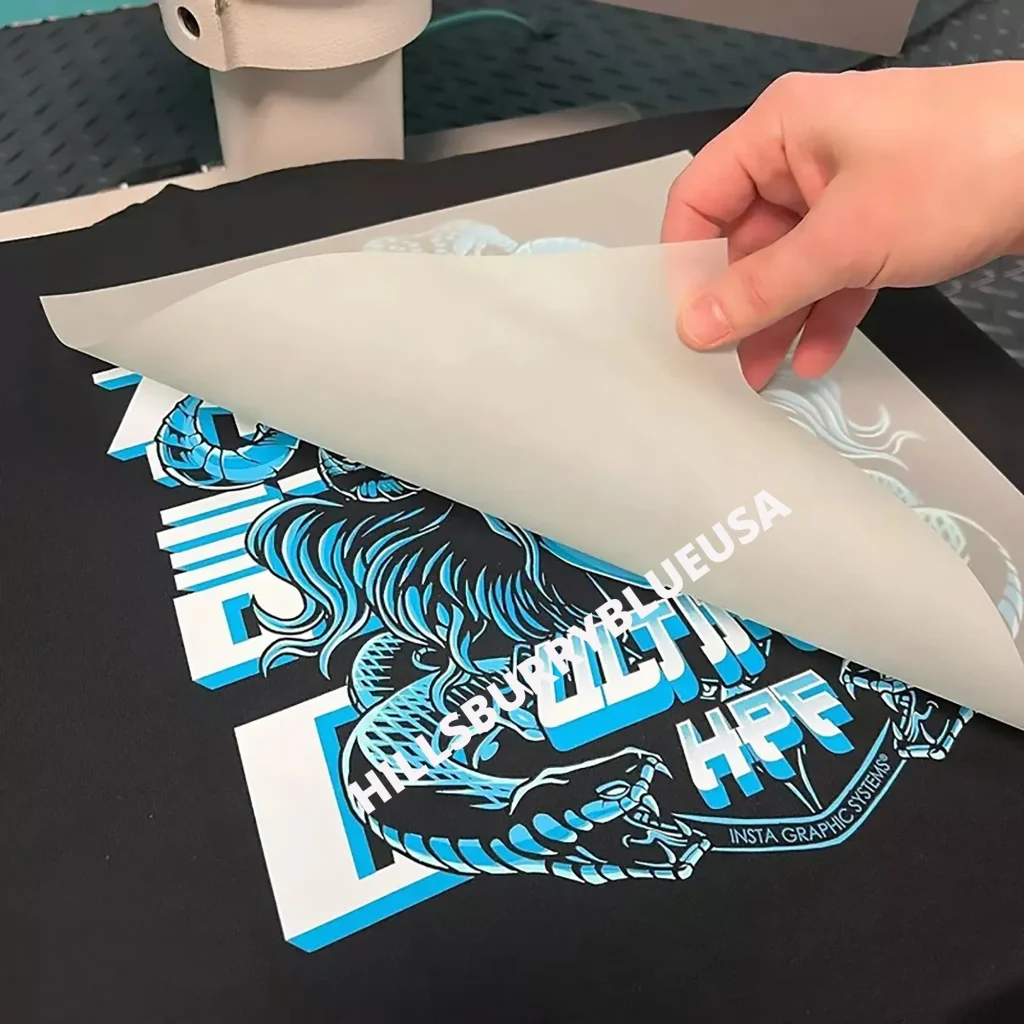

Understanding the printing process for DTF transfers is key to achieving professional results. Begin by loading your transfer film into the printer, ensuring you set the printer settings according to the manufacturer’s guidelines. Printing your design in mirror mode is crucial, as it prepares the artwork for accurate transfer. Following these initial steps will set the tone for the entire printing experience.

After printing, apply the adhesive powder over the wet ink evenly. This helps create a strong bond between the ink and the transfer film, which is vital for the longevity of the design once transferred. Following the curing process with a heat press is essential to properly fuse the ink and powder, making sure the transfer is ready for the final application on fabric. Each step in this process bolsters the quality and reliability of your DTF prints.

Best Practices for Post-Printing Care of DTF Transfers

Once you’ve successfully completed your DTF transfer, proper post-printing care is essential to preserve the vibrancy and longevity of your designs. Start by washing your DTF-printed garments inside out on a gentle cycle, using mild detergents to avoid deterioration. Keeping these items separated from harsh chemicals like bleach will further protect the integrity of your prints.

Drying is another crucial factor; it’s advisable to air-dry your DTF apparel or use a low heat setting in the dryer. High temperatures can cause adhesive weakening and color fading, jeopardizing the quality of your work. By following these best practices in post-printing care, you ensure that your custom apparel featuring DTF designs remains as stunning as the day you created them.

Frequently Asked Questions

How to create DTF designs that stand out?

Creating standout DTF designs begins with understanding design principles such as color theory, balance, and simplicity. Use high-resolution images (300 DPI) and ensure your artwork is in a suitable format like PNG. Experiment with colors that pop on your chosen fabric and remember to keep your designs visually balanced and easy to follow.

What are the best DTF transfer materials for vibrant results?

The best DTF transfer materials include high-quality transfer film, DTF-compatible inks, and a reliable heat press machine. Look for films with excellent adhesive properties. Using vibrant, high-quality inks enhances the durability and brightness of the prints on various fabric types, ensuring your custom apparel looks great.

What are some essential tips for DTF transfer printing?

When performing DTF transfer printing, ensure to print your designs in mirror mode to facilitate proper transfer. Use high-quality materials and maintain the right settings on your printer. After applying the design with a heat press, let it cool before peeling, and consider a second press for increased durability.

How do I prepare my design for DTF transfer printing?

To prepare your design for DTF transfer printing, start by creating a high-resolution image (300 DPI), save it in PNG or vector format, and remember to mirror the image before printing. It’s also essential to ensure the design fits the material and adheres to the fabric seamlessly.

Can I create custom apparel with DTF transfers?

Yes, DTF transfers are excellent for creating custom apparel! They allow for vibrant and intricate designs, making them suitable for T-shirts, hoodies, and other garments. Just ensure you have the right materials and follow best practices in the printing and pressing process for the best results.

What are some common mistakes to avoid when using DTF transfers?

Common mistakes to avoid include printing without mirroring the design, using low-quality materials, and not preheating the heat press appropriately. Additionally, ensure that the adhesive powder is applied evenly and that you allow enough time for the transfer to cool before peeling.

| Key Point | Description |

|---|---|

| What Are DTF Transfers? | A method that transfers designs directly onto fabric using special film, known for high-quality prints. |

| Understanding Design Principles | Focus on color theory, balance, and simplicity to create effective designs. |

| Preparing Your Design | Ensure high resolution, choose the right file format, and mirror your image before printing. |

| Selecting Quality DTF Supplies | Use high-quality transfer films and DTF-compatible inks for vibrant and long-lasting prints. |

| The Printing Process | Load the film, print in mirror mode, apply adhesive powder, and cure with heat. |

| Transferring the Design to Fabric | Preheat the heat press, position the transfer correctly, and apply pressure at the right temperature. |

| Post-Printing Care | Wash inside out gently and air dry to maintain print quality. |

Summary

DTF Transfers are a powerful method for creating unique and vibrant designs on fabric, suitable for both professional and hobbyist crafting. With a solid understanding of design principles, quality materials, and proper printing techniques, you can produce standout prints that are not only visually appealing but also durable. Embrace the versatility of DTF Transfers, whether for custom apparel or promotional items, and let your creativity shine through as you explore the vast potential of this innovative printing technology.