The DTF printing process, or Direct to Film printing, is revolutionizing the way custom apparel is produced, offering vibrant colors and unparalleled flexibility. This innovative technology allows artists and businesses to transfer high-quality images onto fabrics, combining efficiency with stunning visual impact. Unlike traditional fabric printing methods, DTF printing technology utilizes specialized printers to create detailed designs on a film, which is then heat-pressed onto the desired textile. The DTF process benefits from superior ink adhesion, making the prints durable and ideal for diverse fabric types. As digital fabric printing continues to evolve, the DTF process stands at the forefront, enabling personalized printing solutions that cater to modern demands in the fashion industry.

Direct to Film (DTF) printing encapsulates a groundbreaking approach to creating fabric designs, transforming the landscape of custom apparel production. Often referred to as the DTF method, this printing technique leverages advanced technology to apply intricate artworks onto fabrics with remarkable clarity and color fidelity. By employing a heat-transfer strategy, this process offers significant advantages over classic fabric printing methods, streamlining production while maintaining high quality. The utilization of specialized films in this process not only enhances vibrancy but also ensures durability, making it an enticing option for businesses looking to innovate in the realm of digital fabric printing. As more creators and entrepreneurs recognize the potential of DTF methodologies, this form of printing is rapidly becoming a staple in modern garment manufacturing.

Understanding the DTF Printing Technology

Direct to Film (DTF) printing technology represents a significant breakthrough in digital fabric printing, allowing for versatile and high-quality custom apparel designs. Unlike traditional printing methods, DTF integrates advanced processes that enable the application of vibrant colors and intricate designs directly onto films, which are subsequently transferred onto fabrics. By utilizing specially formulated inks, DTF ensures durability and resistance to wear and tear, making it ideal for various applications ranging from promotional graphics to personalized attire.

The essence of DTF technology lies in its ability to combine the best features of several printing methods. It allows for full-color prints with gradients and detailed images that were previously difficult to achieve. The use of a specialized heat-activated adhesive further enhances the transfer process, creating a bond that can withstand multiple washes without fading. Consequently, businesses looking to adopt DTF printing find it increasingly attractive for producing eye-catching designs at a lower cost compared to conventional techniques.

The Benefits of the DTF Process for Custom Apparel

The DTF printing process provides a multitude of benefits, particularly for custom apparel printing. One significant advantage is flexibility: DTF can be applied to a wide range of fabrics, including cotton, polyester, and blends. This versatility enables brands to cater to diverse customer preferences and market demands, expanding their product lines without the constraints associated with traditional printing methods. Additionally, DTF offers an efficient way to produce short runs and personalized items, meeting the growing trend towards custom products.

Moreover, the DTF process enhances the quality of prints while proving to be cost-effective. Businesses that utilize DTF can create intricate designs with bright colors and excellent detail, all while reducing setup costs compared to other techniques like screen printing. This is particularly beneficial for small businesses and startups that may struggle with large upfront investments. Ultimately, the DTF printing technology empowers businesses to thrive in a competitive landscape by delivering high-quality, customized apparel without breaking the bank.

How to Optimize the DTF Printing Process

To maximize the effectiveness of the DTF printing process, it is essential to understand and optimize each stage from design creation to final application. Starting with high-resolution digital designs is key, as this sets the foundation for the quality of the finished product. Selecting the right graphic design software and ensuring images are formatted correctly can lead to stunning outcomes that captivate customers.

Additionally, proper handling of the DTF film and inks throughout the printing process plays a crucial role in achieving optimal results. Maintaining printer calibration and cleanliness can prevent common issues like smudging or uneven prints. As users become better acquainted with the technology through practice and research, they can refine their techniques and uncover innovative ways to exploit the DTF process’s full potential, ultimately leading to superior fabric printing results.

Recent Innovations in DTF Printing

The DTF printing landscape is characterized by continuous innovation and the emergence of new technologies that enhance print quality and environmental sustainability. Recent advancements have led to the development of high-speed DTF printers capable of producing intricate designs more efficiently than ever. These machines also incorporate advanced ink formulations that deliver richer colors and better adhesion, making them suitable for various fabric types.

Moreover, the trend towards eco-friendly inks and materials is gaining momentum in the DTF industry. Manufacturers are increasingly focusing on reducing the environmental impact of their products by creating biodegradable inks and adhesives. This shift aligns with a growing consumer demand for sustainable and responsibly produced apparel, thus giving businesses leverage in marketing their products as environmentally friendly.

Market Trends Shaping DTF Printing

The DTF printing market is experiencing transformative changes driven by consumer preferences and technological advancements. With the increasing popularity of e-commerce and bespoke products, businesses are gravitating toward DTF technology to provide customers with unique apparel options. This shift is particularly evident in small business settings, where DTF printing facilitates affordable, small-batch productions without the extensive resources required for conventional methods.

Additionally, the versatility of DTF printing allows for experimentation across various fabric substrates. While performance textiles are gaining traction in the marketplace, DTF has demonstrated its adaptability to materials beyond cotton, thereby broadening its appeal across different sectors. As these market trends evolve, they reflect the potential of DTF printing to revolutionize custom apparel manufacturing and push creative boundaries.

Addressing Challenges in the DTF Printing Process

Despite its numerous advantages, the DTF printing process poses certain challenges that businesses must navigate to optimize output quality. One of the primary hurdles is maintaining the printers, which can be complex due to specific maintenance needs of DTF machinery. Regular cleaning, calibration, and careful handling of inks and films are critical to ensure seamless production and prevent operational downtime.

Additionally, the learning curve associated with DTF printing can deter some users from fully embracing this technology. New operators may feel overwhelmed initially; however, numerous online resources, forums, and communities provide valuable troubleshooting tips, tutorials, and support for budding DTF printers. By leveraging these tools and engaging with peers, individuals can more easily overcome challenges and take full advantage of what DTF printing has to offer.

Frequently Asked Questions

What is the DTF printing process and how does it work?

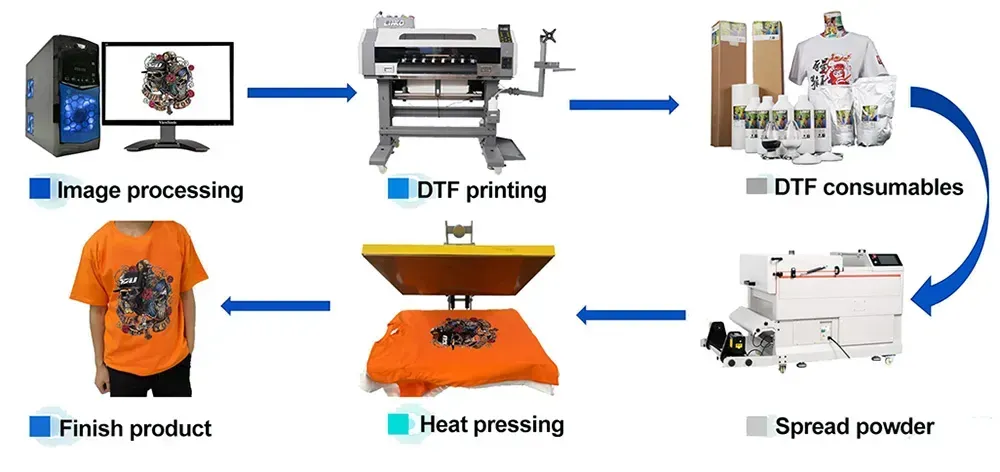

The DTF printing process, or Direct to Film printing, involves transferring designs onto a special film before applying them to fabric. It begins with creating a digital design, printing it onto a coated film using specialized DTF printers, applying an adhesive powder, curing the print, and finally heat pressing it onto the desired garment.

What are the benefits of using DTF printing technology for custom apparel printing?

DTF printing technology offers numerous benefits for custom apparel printing, including vibrant color output, flexibility in design options, compatibility with diverse fabric types, and lower setup costs compared to traditional methods. It also allows for high-quality, detailed prints that are durable and resistant to wear.

How does the DTF process differ from traditional screen printing?

The DTF process differs from traditional screen printing by using a film as an intermediary, allowing for more intricate designs and colors without the need for multiple screens. It also requires lower startup costs and enables easier customization for small runs or unique designs, making it ideal for custom apparel printing.

What types of fabrics can be used with DTF printing?

DTF printing is versatile and can be used on a variety of fabrics including cotton, poly blends, and even some synthetic materials. This compatibility allows businesses to diversify their product offerings and cater to a broader audience within the custom apparel market.

What challenges might one face with DTF printing and how can they be addressed?

Challenges in DTF printing include maintenance of the printers and mastering the learning curve for new users. These can be mitigated through regular maintenance, accessing manufacturer support, and engaging with online communities for tips and troubleshooting. Resources like tutorials can significantly aid in overcoming these hurdles.

Is DTF printing environmentally friendly compared to other printing methods?

DTF printing can be more environmentally friendly than some traditional printing methods. Many manufacturers are now producing eco-friendly inks and adhesives, reducing environmental impact while maintaining print quality. This shift aligns with the growing trend toward sustainability in the custom apparel printing industry.

| Key Point | Details |

|---|---|

| What is DTF Printing? | DTF printing (Direct to Film) allows artworks to be printed on a special film for transfer onto fabrics, providing high-quality, customizable prints. |

| The DTF Printing Process | 1. Creating the Design 2. Printing on Film 3. Applying Adhesive 4. Curing the Print 5. Heat Pressing onto Garment |

| Recent Developments | – Improved Print Quality – Eco-Friendly Options |

| Market Trends | – Growth in demand from e-commerce – Viability for small businesses |

| Challenges | – Printer maintenance issues – Steep learning curve |

| Community Support | Various online resources and communities provide assistance and share knowledge among users. |

Summary

The DTF printing process represents a transformative leap in the realm of fabric printing, combining affordability, versatility, and exceptional quality. This innovative technique has opened new avenues for businesses and artists alike, allowing for detailed and vibrant designs that cater to diverse fabric types. As the technology matures, eager adopters are finding DTF printing not only meets their creative needs but also positions them competitively in the rapidly shifting market landscape. Through continuous advancements and community support, DTF printing is poised to redefine custom apparel production, paving the way for an exciting future in textile personalization.