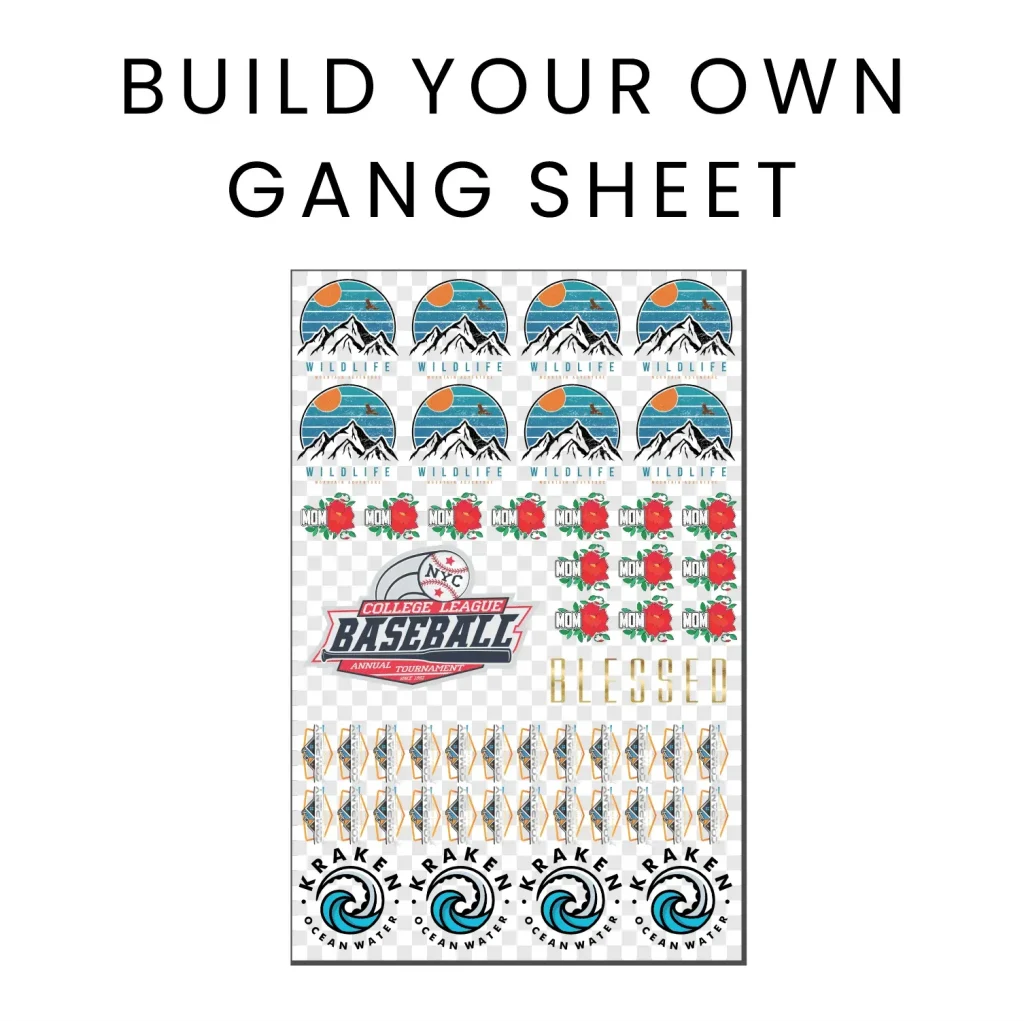

DTF Gangsheet Printing is revolutionizing the way custom apparel is produced, making it a must-know technique for both professionals and enthusiastic beginners. This cutting-edge printing method allows for multiple designs to be printed on a single sheet, optimizing resources and reducing costs significantly. As you dive into the realm of DTF, understanding the intricacies of how to use DTF printing effectively becomes essential for achieving vibrant and durable results. In this guide, we will share valuable DTF printing tips, explore the best DTF printers available, and provide comprehensive insights tailored for DTF printing for beginners. Prepare to unleash your creativity on fabric as we unravel the secrets of DTF gangsheet printing!

Exploring the realms of gang sheet printing—often referred to as direct-to-film (DTF) printing—opens a treasure trove of possibilities for custom garment creation. This method specializes in allowing multiple graphics to be printed simultaneously on a film, benefiting both artists and businesses with efficiency and economic advantages. Whether you’re a seasoned printer or just starting your journey in the world of custom textiles, mastering DTF techniques is key to achieving standout results. In this article, we will delve deeper into DTF printing essentials, offer guidance for newcomers, and unveil industry recommendations to enhance your understanding. Get ready to embark on a creative adventure in printing!

Understanding DTF Printing: A Beginner’s Guide

Direct-to-Film (DTF) printing is a revolutionary technique that has gained traction in the custom apparel industry. Unlike traditional screen printing that requires extensive setup and is often limited to larger runs, DTF printing allows for multiple designs to be printed on a single sheet. This capability is particularly beneficial for small businesses and hobbyists who want to offer a wide variety of apparel without incurring excessive costs. With DTF printing, you can quickly transfer vibrant designs onto different fabrics, ranging from cotton to polyester, which broadens your product offerings significantly.

For beginners eager to learn how to use DTF printing effectively, it’s essential to understand the core components involved. The process begins with a high-quality DTF printer specifically designed to handle transfer films and specialized inks. As you delve further, having a heat press machine that ensures proper adhesion and temperature control becomes critical. Prioritizing equipment quality helps you achieve stunning results right from your first print, avoiding many pitfalls beginners often face.

Key DTF Printing Tips for Success

When embarking on your DTF printing journey, certain tips can significantly enhance your experience and outcomes. First and foremost is the importance of design preparation. Using graphic design software, arrange your designs meticulously to maximize space on the gang sheet. This strategy not only ensures cost-effective printing but also allows the printer to work efficiently without unnecessary wastage. Furthermore, keeping an eye on color management throughout this process is crucial—consistent color output can make a considerable difference in the final product’s appearance.

Another vital tip is to experiment with the layering and transparency of your designs. DTF printing allows for intricate details and vibrant colors, which can be further optimized by implementing transparent backgrounds that provide depth. Additionally, it’s advisable to conduct test prints to determine the ideal settings for different materials, ensuring a flawless transfer each time. By taking the time to adjust temperature and pressure settings according to fabric types, you greatly enhance the durability and quality of your prints.

Best DTF Printers: What to Look For

Choosing the right DTF printer is one of the fundamental steps in beginning your DTF printing journey. Since this technology is relatively new, the market now offers various models that cater to different budgets and requirements. Look for printers that are specifically labeled for DTF printing, as they are designed to handle the particular inks and transfer films needed for producing high-quality designs. Key features to consider include print resolution, speed, and compatibility with a variety of fabrics.

In addition to printer specs, also pay attention to user reviews that can provide insights into real-world performance. Devices made by reputable manufacturers are typically preferred, as they often come with support resources, which can be invaluable for beginners. Investing in a top-tier DTF printer means fewer headaches down the line and a smoother creative process, enabling you to deliver exceptional results with each print.

Common Mistakes in DTF Printing and How to Avoid Them

As with any new venture, beginners in DTF gangsheet printing may encounter common pitfalls that can hinder their progress. One prevalent mistake is neglecting to pre-press garments before applying DTF transfers. This crucial step removes moisture and prepares the fabric surface, leading to better adhesion of the transfer design. Failing to do so can result in underwhelming final products that may peel or fade prematurely.

Another frequent misstep is incorrect design sizing. Measurements should be precise to ensure that designs fit well within the specified areas of the gang sheet. Oversized designs not only waste valuable material but also detract from the overall aesthetics of the apparel. To prevent this, take the time to measure everything carefully and make necessary adjustments to maintain a professional appearance.

Advanced Techniques in DTF Printing you Need to Know

As you become more comfortable with DTF gangsheet printing, exploring advanced techniques can set your work apart from competitors. Techniques such as using gradient effects in your designs can create stunning visuals that tap into customer preferences for uniqueness and creativity. By mastering these skills, you not only enhance the aesthetic appeal of your work but also improve your ability to attract a loyal customer base.

Additionally, advanced color management techniques can further elevate the quality of your prints. Utilizing color profiles and calibration tools can ensure that the colors you see on your screen closely match the final output on fabric. This attention to detail not only leads to customer satisfaction but also builds a strong reputation for your brand in the competitive custom apparel market.

Resources for Mastering DTF Printing

To further your understanding of DTF gangsheet printing techniques, numerous resources are at your disposal. Online platforms like Printify and Epson provide comprehensive guides that not only cover the basics of how to use DTF printing but also delve into equipment recommendations and advanced strategies for enhancing your output. These resources are instrumental for both beginners and those looking to refine their skills as they provide clear instructions and industry insights.

In addition to blogs and articles, YouTube is a goldmine for learning about DTF printing through visual tutorials. By searching for channels dedicated to DTF gangsheet tips, you can find a plethora of step-by-step walkthroughs, from initial setup guidance to troubleshooting tips. Engaging with these resources can help solidify your understanding and boost your confidence as you embark on your DTF printing journey.

Frequently Asked Questions

What is DTF gangsheet printing used for?

DTF gangsheet printing is primarily used for creating vibrant transfer prints that can be applied to a variety of fabrics, making it ideal for custom apparel production. This method allows multiple designs to be printed on a single sheet, maximizing material usage and production efficiency.

How to use DTF printing for your designs?

To use DTF printing effectively, start by preparing your designs in graphic software, ensuring optimal sizing for the gang sheet. Print on specialized transfer film, apply a powder adhesive, and then use a heat press machine to transfer the designs onto your target fabric, following recommended temperature and pressure guidelines.

What are some essential DTF printing tips for beginners?

Some essential DTF printing tips for beginners include careful design preparation, managing colors accurately, utilizing layering techniques, and experimenting with temperature and pressure settings during heat transfer. Pre-pressing fabrics before applying transfers is also crucial for optimal results.

What are the best DTF printers available for beginners?

For beginners, some of the best DTF printers include those that are specifically designed for DTF technology, ensuring compatibility with transfer films and specialty inks. Look for brands that are known for reliability and quality, and consider discussing with experienced DTF users for recommendations.

What common mistakes to avoid in DTF gangsheet printing?

Common mistakes to avoid in DTF gangsheet printing include skipping the pre-pressing step, miscalculating the size of designs, and using low-quality transfer films or inks. Properly measuring designs and opting for high-quality materials are essential for achieving the best print quality.

Where can I learn more about DTF gangsheet printing techniques?

You can learn more about DTF gangsheet printing techniques through resources like Printify’s guide on starting DTF printing, Epson’s insights on equipment, and YouTube tutorials that focus on DTF gangsheet tips. These resources provide valuable knowledge and practical advice for honing your skills.

| Key Points | Details |

|---|---|

| Introduction to DTF Gangsheet Printing | DTF gangsheet printing is a method for creating transfer prints that can be used on various fabrics, maximizing efficiency by allowing multiple designs on a single sheet. |

| How DTF Printing Works | It uses a DTF printer, prints onto transfer film, coats with adhesive powder, and uses heat pressing to transfer designs onto garments. |

| Essential Equipment | A DTF printer, heat press machine, quality transfer film, and powdered adhesive are necessary for successful printing. |

| Tips for Beginners | 1. Prepare designs using graphic software. 2. Manage colors carefully. 3. Use transparent backgrounds. 4. Optimize temperature and pressure settings. |

| Mistakes to Avoid | Avoid skipping pre-pressing, incorrect sizing of designs, and using low-quality materials for better results. |

| Resources for Further Learning | Resources include Printify and Epson guides and various YouTube channels to enhance your knowledge on DTF printing. |

Summary

DTF Gangsheet Printing is a revolutionary approach to custom apparel, designed for enhancing creativity while optimizing resources. This printing technique allows artists and entrepreneurs to consolidate multiple designs onto a singular sheet, effectively reducing waste and costs. By leveraging specialized DTF printers, high-quality transfer films, and precise temperature controls, you can achieve vibrant and long-lasting prints on various fabrics. Starting with a solid understanding of DTF technology, equipping yourself with the right tools, and following beginner tips helps ensure your success in this realm. Always aim to continuously educate yourself through available resources, paving the way for mastery in DTF Gangsheet Printing and transforming your unique designs into tangible fashion statements.