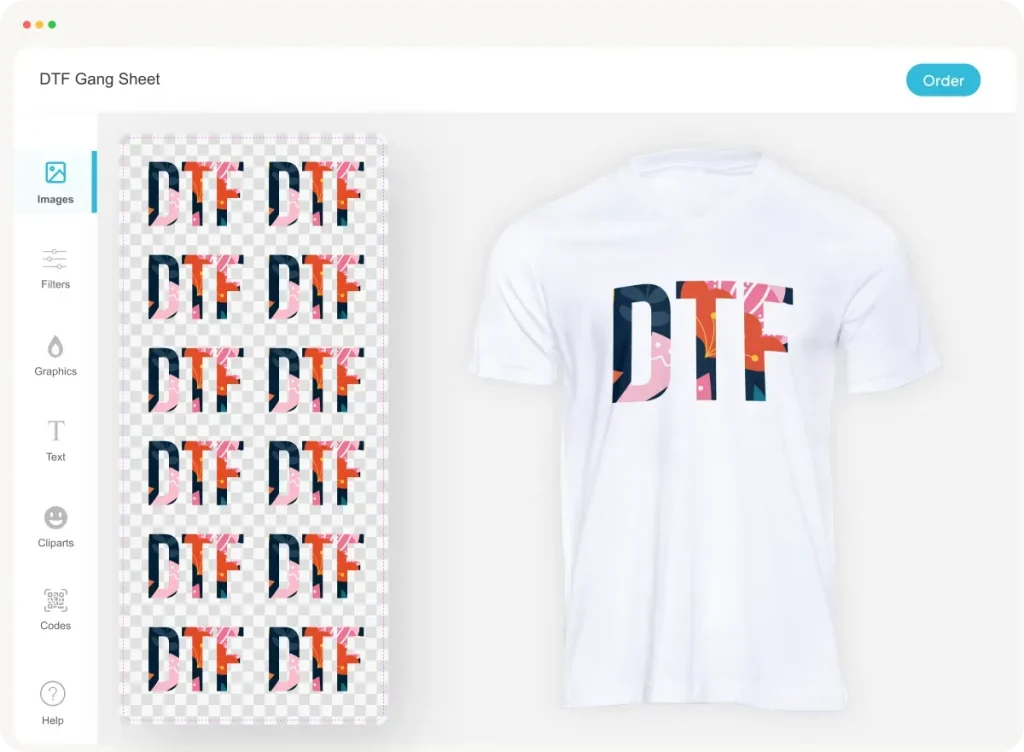

In the world of textile printing, DTF gangsheet builders stand out as innovative tools that simplify the printing process while enhancing the quality of the output. These builders allow users to produce vibrant, high-quality prints using Direct to Film printing techniques that are both efficient and cost-effective. Understanding how to properly utilize DTF transfer techniques can significantly impact the success of your projects, leading to superior designs and increased customer satisfaction. Additionally, selecting the right DTF film and following essential DTF printing tips are crucial elements for achieving optimal results. With the right knowledge and tools, harnessing the power of DTF gangsheet builders can elevate your printing endeavors to new heights, ensuring every project is a masterpiece.

Known as Direct to Film printing specialists, DTF gangsheet builders revolutionize how designs are transferred onto fabrics, offering a streamlined solution for printmakers. By employing advanced DTF transfer techniques, these builders make it easier to create stunning prints on various materials, including cotton and polyester blends. The benefits of using high-quality DTF film selection and correctly adjusting heat transfer printing parameters cannot be overstated, as they play a significant role in the durability and vibrancy of the final product. For those looking to enhance their printing capabilities, understanding these alternative terminology concepts surrounding DTF printing is essential for mastering the technique. This guide will arm you with the foundational skills needed to excel in your DTF printing journey.

Choosing the Best DTF Film for Your Needs

Selecting the right DTF film is a crucial step in achieving outstanding print results. The compatibility of the film with your printer and ink can significantly affect the vibrancy and durability of your designs. High-quality DTF films are designed to promote excellent color reproduction, ensuring that the images you print are both vivid and long-lasting. Additionally, be sure to read product reviews and manufacturer guidelines for insights on which films perform best under different conditions. By making an informed choice, you set the foundation for high-quality outputs.

DTF films also come in various thicknesses and coatings, which can impact the transfer process. Some films are designed for specific fabric types, making it essential to consider the fabrics you will frequently use. For instance, if you primarily print on polyester fabrics, look for films that have been tested for compatibility with high polyester content. By understanding the sheet properties and matching them with your fabric, you enhance the chances of achieving a flawless print.

Optimizing Ink Quality for DTF Printing Success

The ink you choose plays a pivotal role in your DTF printing outcomes. It is imperative to select inks specifically formulated for the DTF printing process, as they ensure better adhesion and vibrant color accuracy. These specialty inks often yield superior performance on a variety of substrates when compared to generic inks. Regular maintenance of your printer is also essential to ensure that no clogs or performance issues arise. By prioritizing ink quality and printer upkeep, you enhance overall print quality.

Regularly testing and calibrating ink flow can provide additional benefits. This process allows you to identify any inconsistencies in color reproduction and make adjustments to achieve the desired results. Before initiating large-scale prints, testing out your ink on small samples can help confirm that the inks bond correctly with your chosen DTF film and fabric, saving you time and materials in the long haul.

Key Printer Settings for Optimal DTF Transfers

Adjusting your printer settings is essential to unlocking the full potential of your DTF gangsheet builders. Enhance your ink density for rich color saturation, which is particularly important for detailed designs. Utilizing the maximum resolution your printer allows can also provide clarity and sharpness that makes your prints stand out. Furthermore, consider customizing other settings based on your specific project requirements, especially when printing on various fabric types.

It’s beneficial to keep a record of your printer settings for different fabric and film combinations. This way, you can easily replicate successful prints and make necessary adjustments for new designs. Consistent calibration is another preventive measure that can reduce the variability of your prints over time, ensuring a high quality in each output you produce.

Managing Heat and Pressure for Successful Transfers

Heat and pressure settings are fundamental factors in the DTF transfer process. Each film and fabric combination may require distinct settings, so consulting product instructions becomes crucial. Applying consistent and correct heat can avert issues such as poor adhesion and uneven transfers. Therefore, invest in a reliable heat press that allows for precise adjustments and maintain it regularly to ensure even pressure distribution.

Monitoring the timing of your transfer process is equally important. Overheating or insufficient time under pressure can lead to subpar results, wasting both materials and time. Implementing a steady protocol for testing these parameters will improve your ability to achieve consistent, high-quality transfers in your projects.

Pre-Treatment: Enhancing Fabric Compatibility for DTF

Pre-treating fabrics is a practice that shouldn’t be overlooked for certain materials. While not all fabrics require pre-treatment, it can significantly improve ink adhesion, especially with synthetic fibers that might not bond well with DTF inks. This step can be particularly beneficial for high polyester materials, where the treatment acts as a bridge enhancing the bond between the fabric and the printed design.

Experimenting with pre-treatment options on small fabric samples can help determine the best approach tailored to your specific fabrics. Knowing whether your fabric requires pre-treatment can save the hassle of redoing prints or dealing with fading over time. Implementing this process ensures longevity and vibrancy in your final product.

Design Preparation for Flawless DTF Prints

Meticulously preparing your designs is critical in the DTF printing process. Utilizing graphic design software allows for precise adjustments in dimensions and resolution, ensuring that your final prints meet your expectations. The precision of your design translates directly to the quality of your final product, making this a pivotal step in the preparation phase. Investing time in refining your graphics can yield significant improvements in your print outcomes.

Additionally, considering the color palette and design intricacies is vital in this step. Ensure that the colors selected are compatible with the inks and film used for your projects. By preparing high-quality, vibrant designs, you maximize your chances of producing stunning prints that stand out.

Frequently Asked Questions

What are DTF gangsheet builders and how do they work?

DTF gangsheet builders are tools that facilitate the production of high-quality prints using Direct to Film (DTF) technology. They work by allowing users to arrange multiple designs on a single film sheet, optimizing print space and reducing material costs. This technique is crucial for efficient DTF printing, enabling vibrant graphics to be transferred onto various fabrics.

What are some essential DTF printing tips for using gangsheet builders?

Key DTF printing tips include selecting high-quality DTF films compatible with your printer, using specialized DTF inks for better adhesion and color accuracy, and adjusting printer settings for optimal resolution. Additionally, pre-treating the fabric when necessary and conducting regular testing can significantly enhance the final print quality when utilizing DTF gangsheet builders.

How can I choose the right DTF film for my gangsheet printing?

To select the right DTF film for your gangsheet printing, ensure compatibility with your specific printer and ink type. Look for films that provide excellent color reproduction and durability based on product reviews and manufacturer recommendations. The right DTF film can greatly impact the vibrancy and longevity of your transfers.

What are effective DTF transfer techniques when using gangsheet builders?

Effective DTF transfer techniques include ensuring proper temperatures and pressures during the heat transfer process and using an intermediary silicone sheet to stabilize the transfer. Furthermore, calibrating your heat press for even pressure distribution enhances adhesion and overall transfer quality, critical when using DTF gangsheet builders.

Why is pre-treating fabric important in DTF printing with gangsheet builders?

Pre-treating fabric is important in DTF printing as it enhances the adhesion of DTF inks, particularly on synthetic materials like polyester that may not bond well naturally. This step reduces the likelihood of fading and improves the overall quality of the transfer, ensuring better results with DTF gangsheet builders.

How should I store and handle DTF films and printed materials?

To maintain the quality of DTF films and printed materials, store them in a cool, dry environment away from humidity and temperature fluctuations. Proper storage practices help extend the life of your films and preserve the vibrancy of your prints, which is essential for successful DTF printing using gangsheet builders.

| Tip | Description |

|---|---|

| Selecting the Right DTF Film | Choose compatible and high-quality DTF film for vibrant and durable prints. |

| Use Quality Inks | Opt for DTF-specific inks to ensure better adherence and color accuracy. |

| Adjust Printer Settings | Optimize settings for ink density, print resolution, and calibration. |

| Temperatures and Pressures Matter | Follow product guidelines for correct heat and pressure application. |

| Pre-Treat Fabric When Necessary | Enhance ink adhesion, especially for high-polyester fabrics. |

| Design Preparation | Refine graphics to proper dimensions and resolution for printing. |

| Implement Proper Transfer Techniques | Use silicone sheets during transfer to stabilize and protect designs. |

| Store and Handle Materials Correctly | Keep materials in a cool, dry place to maintain quality. |

| Conduct Regular Testing | Perform test prints to ensure quality before large runs. |

Summary

DTF Gangsheet Builders play a crucial role in enhancing your textile printing processes. By implementing the tips outlined in this guide, you can maximize the efficiency and quality of your prints, ensuring superior results. Understanding how to select the right film, use quality inks, and optimize your printer settings are just a few of the essential strategies that can help you excel in DTF printing. As you integrate these practices into your workflow, you’ll be better equipped to produce vibrant, long-lasting designs that impress your customers. Whether you are a seasoned professional or just beginning your journey, these insights will significantly improve your approach to DTF printing. Happy printing!