In today’s competitive DTF printing landscape, the DTF gangsheet builder is a strategic workflow decision. It helps you maximize sheet utilization, cut setup time, and reduce material waste. It clarifies the often debated DTF gangsheet vs manual layout, showing how automation can outperform manual approaches in throughput and consistency. Compared with a manual layout for DTF, the DTF gangsheet builder standardizes margins and color placement, reducing human error across runs. When integrated with DTF printing automation, this approach boosts production efficiency in DTF while keeping costs predictable.

For shops exploring the benefits of automation, a gangsheet automation tool can consolidate multiple designs onto a single sheet, improving planning and resource use. This flow relies on automated tiling, margin control, and color management to replicate results across runs, rather than manual placement. Latent Semantic Indexing (LSI) principles point to related terms such as batch printing, layout optimization, and production efficiency in DTF, helping search engines connect the concept to DTF printing automation and quality control. Whether you call it automated sheet planning, multi-design packing, or layout optimization for heat-transfer transfers, the core aim is faster production with less waste and more consistent transfers.

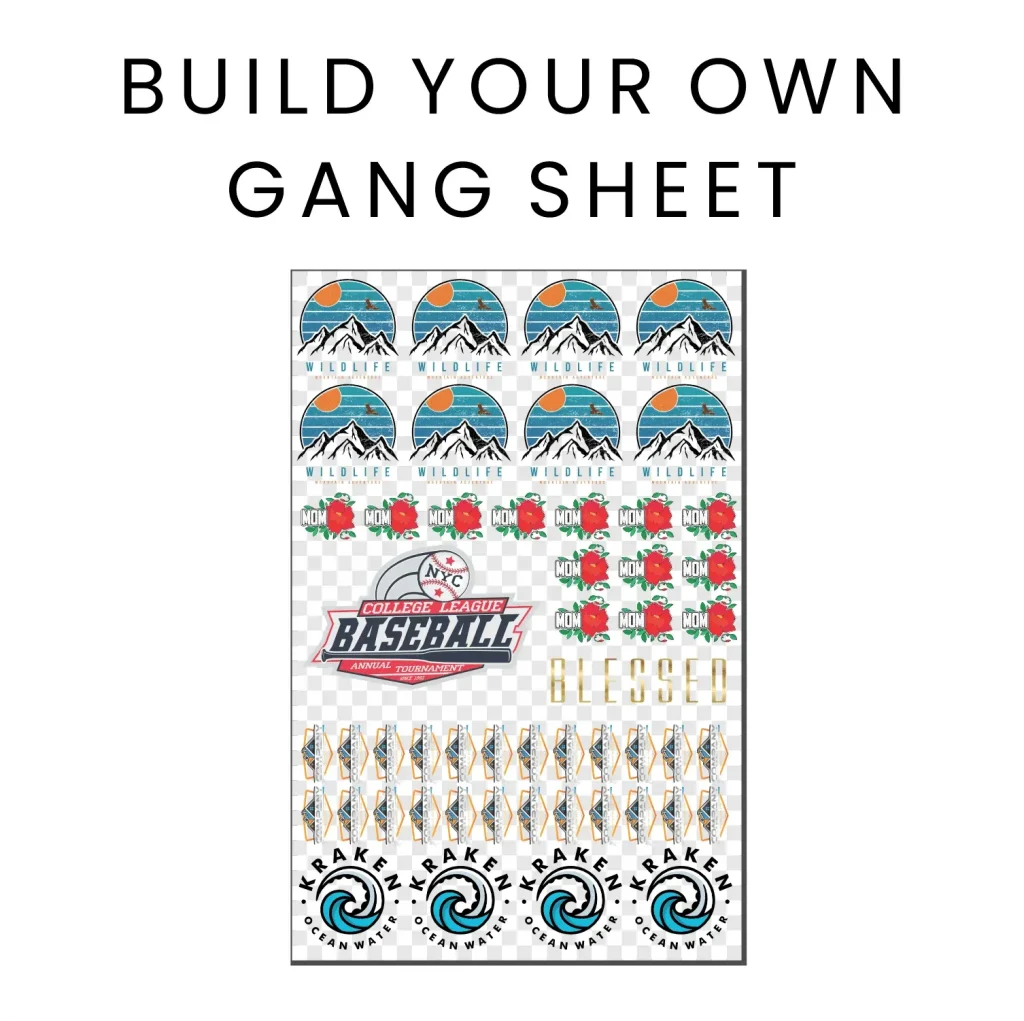

DTF Gangsheet Builder vs Manual Layout: Choosing the Right Workflow for Your Shop

Choosing between a DTF gangsheet builder and a manual layout workflow isn’t just about the latest software—it’s about how your shop operates day to day. A gangsheet builder optimizes the arrangement of multiple designs on a single sheet, improving throughput and reducing setup time. In contrast, manual layout relies on human intuition and hands-on placement, which can be flexible for unique jobs but often slower and more error-prone as volumes grow.

When deciding which path to take, consider your shop size, typical order mix, and tolerance for changes. A gangsheet solution tends to scale better for shops with multiple designs per sheet and higher throughput needs, while manual layout may remain viable for very small runs or highly customized items where bespoke placement is essential.

DTF Printing Automation: How a Gangsheet Builder Streamlines Operations

DTF printing automation is about reducing manual touchpoints and standardizing the workflow from design to transfer. A DTF gangsheet builder brings automatic tiling, margins, and color separation into a single cohesive process, feeding directly into your RIP and printer. This minimizes operator fiddling and aligns layouts for consistent transfers across runs.

Automation also strengthens quality control by enforcing repeatable margins and color placement, making it easier to reproduce a proven layout across dozens or hundreds of transfers. For shops aiming to improve reproducibility, automation reduces misregistrations and color drift, delivering steadier production quality.

Manual Layout for DTF: When Flexibility Trumps Automation

Manual layout for DTF excels in scenarios requiring bespoke design placement, unique substrates, or highly customized orders. In small shops or for one-off prints, human-centric layout can accommodate creative overlaps, special substrates, and nuanced color overlays without waiting for software-driven optimizations.

However, as volumes rise, manual processes can become bottlenecks. The risk of misalignment, inconsistent margins, and added labor costs grows with each design added to a sheet. To mitigate these challenges, invest in targeted training and establish clear workflows that preserve flexibility while maintaining accuracy.

Maximizing Material Use: Waste Reduction with DTF Gangsheet Builder

A core benefit of using a DTF gangsheet builder is material efficiency. By calculating optimal placements and taking account of margins and bleeds, the tool minimizes waste across fabrics or films with fixed dimensions. This not only lowers material costs but also supports sustainability goals, which many customers increasingly value.

Waste reduction also translates to better inventory management and fewer reprints due to misalignment. As the software optimizes sheet utilization, you can accommodate more designs per sheet without sacrificing transfer quality, contributing to tighter production schedules and improved consistency.

Production Efficiency in DTF: Measuring Impact with a Gangsheet Builder

Implementing a gangsheet builder is often justified by gains in production efficiency in DTF. Throughput increases as operators spend less time on placement and more on actual printing and transfer preparation. The system’s batch processing and automated exports help streamline the handoff to RIPs and printers.

To quantify the improvement, track metrics such as sheets per hour, material waste per job, and reprint rates. A data-driven pilot can reveal how much time, material, and labor you save by switching from manual layouts to gangsheet-driven workflows—and whether the payback aligns with your shop’s ROI targets.

From Design to Transfer: Integrating a DTF Gangsheet Builder into Your RIP and Printer

Successful integration means the gangsheet builder’s outputs feed smoothly into your RIP and direct-to-film printer. This includes compatible export formats, clear print order logic, and alignment with your color management workflow. An integrated setup reduces manual adjustments during the transfer phase and helps maintain consistent results across runs.

A practical integration approach starts with a pilot project to validate sheet utilization, color fidelity, and transfer quality. Align standard margins, color profiles, and asset naming conventions to ensure repeatability. Train operators to interpret the software’s reports and troubleshoot common alignment issues, all while tracking KPIs to demonstrate the impact on productivity.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it optimize layouts?

A DTF gangsheet builder is specialized software that arranges multiple designs onto a single sheet (gang sheet) to maximize material use, minimize waste, and streamline setup. It handles tiling, margins, bleed, and color placement, then exports ready gang sheets for your RIP or printer, boosting production efficiency in DTF.

DTF gangsheet vs manual layout: which approach generally improves production efficiency in DTF?

DTF gangsheet vs manual layout often favors the gangsheet approach for throughput and consistency, especially at scale. Manual layout for DTF can work for small runs but is slower and more error-prone, reducing production efficiency in DTF as volumes grow. Automation typically wins on repeatability.

How does DTF printing automation work with a gangsheet builder in a typical shop workflow?

DTF printing automation integrates with a gangsheet builder by feeding artwork, color profiles, and layout parameters from design software into the RIP. The builder automatically tiles, orients, and exports gang sheets, enabling faster setup and consistent results across designs.

What are the benefits and limitations of manual layout for DTF compared with a DTF gangsheet builder?

Manual layout for DTF offers flexibility for unique placements and small runs but is labor-intensive and prone to misregistration and waste at larger scales. A DTF gangsheet builder usually delivers better production efficiency in DTF when volumes rise.

How can you measure ROI and track production efficiency in DTF after adopting a DTF gangsheet builder?

To measure ROI and production efficiency in DTF after adopting a DTF gangsheet builder, track metrics like sheets per hour, material waste per job, reprint rate, setup time, and color consistency. Compare against your previous manual workflow to quantify improvements and payback period.

What steps should a shop take to implement a DTF gangsheet builder for better production efficiency in DTF?

Implementation steps for a DTF gangsheet builder: run a pilot comparing gangsheet layout vs manual layout, standardize margins and color profiles, organize asset libraries, train staff, integrate the gangsheet tool with your RIP/printer, and monitor KPIs (throughput, waste, reprints) to validate impact.

| Aspect | DTF Gangsheet Builder | Manual Layout |

|---|---|---|

| What it is |

A DTF gangsheet builder is a specialized software or workflow tool designed to arrange multiple print designs onto a single sheet (a gang sheet) for DTF transfers. It optimizes fabric or film usage, aligns colors consistently across designs, and minimizes waste during heat pressing. Features often include automatic tiling, rotation options, bleed adjustments, and export formats that feed directly into your RIP or printer. |

Manual layout involves human operators arranging designs on a sheet by hand, often using general design or layout software. While this can work for very small runs or highly customized orders, it tends to be slower and more error-prone as volumes grow. |

| Throughput / Speed |

DTF Gangsheet Builder: Time savings and higher throughput due to automated placement and optimization. Fewer sheets per job translate into faster production and reduced labor per unit. |

Manual Layout: Slower due to manual placement, margins, and bleed adjustments; throughput is limited by operator capacity. |

| Material Utilization & Waste |

DTF Gangsheet Builder: Minimizes waste by calculating the most efficient arrangement, improving material efficiency and supporting sustainability goals. |

Manual Layout: Higher risk of waste from suboptimal layouts and misalignments, especially as volumes grow. |

| Consistency & Color Alignment |

DTF Gangsheet Builder: Enforces standardized margins, bleed, and color placement to deliver repeatable results and reduce misregistration across designs. |

Manual Layout: Can achieve high quality but requires meticulous checks; more prone to color drift or misregistration without automation. |

| Scalability & Workflow Integration |

DTF Gangsheet Builder: Integrates with design software, RIP, and printers, enabling batch processing and exporting multiple gang sheets from a single project. |

Manual Layout: Less scalable; hand-placed designs become bottlenecks as volumes rise. |

| Cost, ROI & Production Efficiency |

DTF Gangsheet Builder: Upfront software or subscription cost; ROI from time savings, reduced waste, and reproducibility, often quick in high-volume shops. |

Manual Layout: Lower upfront cost but higher ongoing labor costs and potential waste; ROI depends on order mix and reprints. |

| Quality Control |

DTF Gangsheet Builder: Supports repeatable placement and color management for consistent results across runs. |

Manual Layout: High quality possible but requires checks; more room for human error and variation. |

| Decision Criteria |

Decision criteria: Shop size and volume, product mix, labor resources, tolerance for change, and emphasis on quality control. |

Note: If these factors align with automation benefits, a gangsheet solution is typically advantageous. |

| Practical Implementation Tips |

Pilot project: Test gangsheet vs manual layouts on a common design set; compare sheets used, waste, and timing. Standards: Define margins, bleed, and color profiles for consistent results. Asset organization: Maintain a clean library with substrate/color profiles for batch processing. Testing & training: Validate alignment; train operators; troubleshoot. KPI tracking: Monitor sheets per hour, waste per job, reprint rate, throughput. |

Notes: Regularly review and update workflows as tools evolve. |

| Common Pitfalls |

Over-optimizing sheet count at the expense of accuracy: Balance material efficiency with reliable alignment. Inconsistent color management: Use standardized color workflows and verify targets on sample runs. Under-testing across substrates: Validate on actual materials to account for substrate effects. Underestimating training needs: Even the best tool requires user proficiency. |

Takeaway: Plan for both tooling and people to realize the full benefits of either approach. |

Summary

DTF gangsheet builder offers a path to greater throughput, tighter material control, and more consistent results as order volumes rise. For shops weighing automation, the choice between a DTF gangsheet builder and manual layout should consider order mix, resource availability, and quality goals. The DTF gangsheet builder approach excels in production efficiency in DTF settings with multiple designs per sheet, while manual layout remains viable for small runs or highly customized jobs. A disciplined pilot, clear standards, and KPI tracking will help determine the best fit for your shop and maximize profitability through reduced waste, faster turnaround, and consistent transfers.