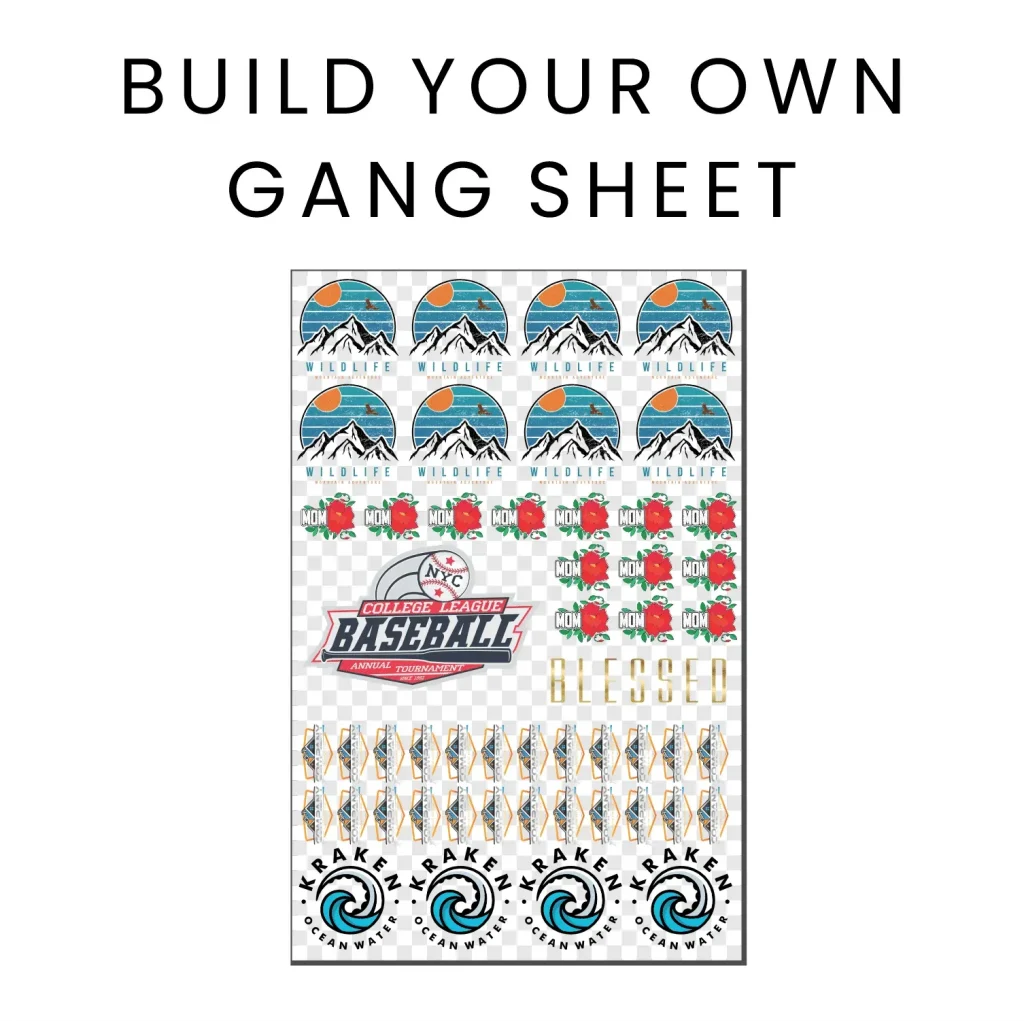

The DTF Gangsheet Builder is a game-changer in the world of direct-to-film printing, offering a powerful tool for creating high-quality, vibrant designs. By utilizing the builder effectively, you can streamline the gangsheet design process, maximizing efficiency while minimizing material waste. This optimized workflow not only enhances your DTF print optimization efforts but also ensures that each project yields professional-grade results. Exploring the intricacies of the DTF gangsheet builder will reveal essential strategies to improve your software proficiency and design techniques. In this introduction, we will outline key tips to help you harness this tool for stunning, reliable prints that your clients will love.

When delving into the realm of direct-to-film innovation, it’s crucial to understand the significance of a gangsheet creator in enhancing print quality and output efficiency. Utilizing advanced techniques in DTF design management can lead to impressive results that stand out in the competitive printing market. This discussion will cover essential practices for optimizing your direct-to-film applications, from ensuring accurate design measurements to refining color profiles for targeted media. As the technology surrounding high-resolution film printing evolves, understanding the nuances of effective software use will set you apart in your creative processes. Join us as we explore practical insights to elevate your printing projects and foster growth within the industry.

The Importance of High-Resolution Images in DTF Printing

High-resolution images (300 DPI or more) are the cornerstone of successful direct-to-film (DTF) printing projects. The clarity and detail captured in high DPI images play an essential role in ensuring your final prints exhibit vibrant colors and sharp lines. Without such detail, the resulting prints may appear dull or distorted, failing to represent the artistic vision of the original design. To achieve the best results, designers and printers must prioritize image quality from the very beginning of the design process.

Additionally, the use of accurate color profiles tailored to your specific printer can significantly enhance the overall output quality. By matching color settings in your design software with those in the printer’s capabilities, you ensure a more true-to-life color representation in your printed materials. This commitment to image quality not only elevates the finished product but also enhances customer satisfaction, as clients are more likely to return for future orders if they receive high-quality prints.

Maximizing Production Efficiency with Accurate Measurements

Utilizing accurate measurements is paramount when designing gang sheets for DTF printing. Ensuring that each design element fits perfectly within the provided dimensions minimizes material waste and prevents unnecessary production delays. Many DTF software tools come equipped with features like grid systems and measurement guides, allowing designers to maintain professional standards in their layouts. This meticulous attention to detail drastically improves the efficiency of the entire production process.

Moreover, maintaining consistent dimensions throughout your designs facilitates smoother transitions from the design phase to actual printing. By adhering to precise measurements, designers can better estimate ink usage and fabric costs, leading to more economical production practices. Ultimately, this focus on accuracy not only enhances workflow efficiency but also positively impacts the financial health of a DTF printing operation.

Streamlining Your Workflow with Effective Layer Management

Layer management is a critical aspect of DTF printing, as it allows for organized and systematic design processes. By categorizing different components—such as patterns, colors, and textures—into separate layers, designers can make targeted adjustments without disrupting the entire project. This approach streamlines the workflow, reducing the time spent making edits and minimizing potential errors that may occur during the printing stage.

Furthermore, effective layer management enhances communication between team members involved in the design and printing processes. When designs are clearly organized, it becomes easier for collaborators to understand the vision and make necessary adjustments. This can lead to improved productivity, quicker turnaround times, and ultimately, the production of higher-quality outputs that meet customer expectations.

The Value of Conducting Test Prints Before Full Production

Conducting test prints is a best practice in DTF printing that can save time and resources. By printing a sample of your gang sheets, you can pinpoint issues related to color discrepancies or design placements that might not be evident on a digital screen. This preliminary step not only helps in refining the designs but also ensures that the final product aligns with the client’s vision and specifications.

Additionally, test prints allow for adjustments to be made before committing to a full production run. This flexibility is crucial, as it provides the opportunity to experiment with different materials and inks to determine the most suitable configurations for achieving the desired results. By prioritizing test printing, you reduce the risk of costly mistakes and enhance the overall quality of your final product.

Becoming Proficient in DTF Design Software for Enhanced Creativity

A strong grasp of DTF design software is essential for maximizing both productivity and the quality of your prints. Software platforms often come with a wealth of resources, including tutorials and user guides, which can help users navigate through complex design tools and features. Mastering these capabilities not only increases efficiency but can also inspire creativity, as designers become more comfortable with exploring advanced styling techniques.

As you develop proficiency in your DTF software, you’ll find that utilizing its advanced features allows for more customization and experimentation within your designs. By understanding the intricacies of your chosen software, whether it’s Adobe Illustrator or a specialized DTF platform, you can create innovative designs that stand out in the competitive printing market. Acquiring this software proficiency can be a game-changer, significantly enhancing the quality of your outputs and improving customer satisfaction.

Keeping Up with Recent Developments in DTF Printing Technology

Staying informed about the latest developments in DTF printing technology is vital for any printing professional looking to remain competitive. Fresh advancements in inks, software features, and printing techniques provide unique opportunities for improving design capabilities and output quality. Engaging with industry webinars, attending online courses, and participating in community forums become essential practices, ensuring that you are updated on the most effective techniques and tools available.

Continued education in the field of DTF printing is crucial as technology evolves at a rapid pace. By investing time into learning about new practices, such as innovative gangsheet designs or improved print optimization methods, you can maintain a cutting-edge operation. Furthermore, staying ahead in technology trends fosters confidence among clients, who appreciate working with informed professionals who can deliver exceptional results using the latest strategies in DTF printing.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance direct-to-film printing?

The DTF Gangsheet Builder is a specialized tool that organizes multiple designs into a single sheet for direct-to-film (DTF) printing. This process increases efficiency by maximizing material use and reducing waste, allowing for high-quality prints and lower production costs.

How can I optimize my images for the DTF Gangsheet Builder?

To optimize images for the DTF Gangsheet Builder, ensure that your files are high-resolution (at least 300 DPI) and use appropriate color profiles that match your printer’s specifications. This will enhance the vibrancy and detail of your final prints.

What role does accurate measurement play in gangsheet design with DTF printing?

Accurate measurements in gangsheet design are crucial to prevent misalignment and material waste. Utilizing grid systems provided by DTF software helps maintain correct proportions and enhances production efficiency, ensuring that each design fits perfectly within the designated dimensions.

Why is layer management important in DTF gangsheet builds?

Layer management is essential in DTF gangsheet builds because it allows you to categorize different design elements separately. This organization facilitates easy adjustments without affecting the entire design, thus streamlining the printing process and enhancing overall productivity.

How do test prints improve the outcome of gangsheet designs in DTF printing?

Conducting test prints is vital for identifying potential color discrepancies and design placement issues before full production. This practice minimizes costly errors and allows for adjustments, ultimately enhancing the quality of the final high-quality prints.

What are some key features to look for in DTF design software for effective gangsheet building?

When selecting DTF design software, look for features like user-friendly interfaces, advanced editing tools, and support for high-resolution images. Proficiency in software tools that integrate with your DTF Gangsheet Builder is critical for maximizing efficiency and output quality.

| Key Point | Description | Related Keywords |

|---|---|---|

| 1. Optimize Image Quality | Utilizing high-resolution images (300 DPI or higher) enhances print detail and vibrancy, increasing customer satisfaction. | DTF printing technology, high-resolution images, printer specifications |

| 2. Utilize Accurate Measurements | Accurate measurements in design prevent material wastage and ensure efficient printing processes. | production efficiency, DTF software tools, grid systems |

| 3. Layer Management | Organizing designs into layers allows easier adjustments, improving productivity and control over elements. | design software, streamline printing process, individual elements |

| 4. Test Prints | Conducting test prints helps identify issues early, minimizing costly mistakes before full production. | color representation, design issues, full production run |

| 5. Software Familiarity | Being proficient in DTF design software improves productivity and allows use of advanced features effectively. | DTF design software, productivity, design process |

| Latest Developments | Continual education and engagement with community forums keep you updated on advancements in DTF technology. | advancements in DTF technology, continued education, community forums |

Summary

DTF Gangsheet Builder is essential for achieving high-quality results in the DTF printing industry. By prioritizing image quality, ensuring precise measurements, managing design layers, conducting thorough test prints, and gaining proficiency in design software, you enhance both the efficiency and quality of your production process. Furthermore, staying abreast of advancements in the DTF technology landscape is vital to remain competitive. Investing in these strategies will lead to beautiful, vibrant prints that satisfy customer demands and drive business growth.