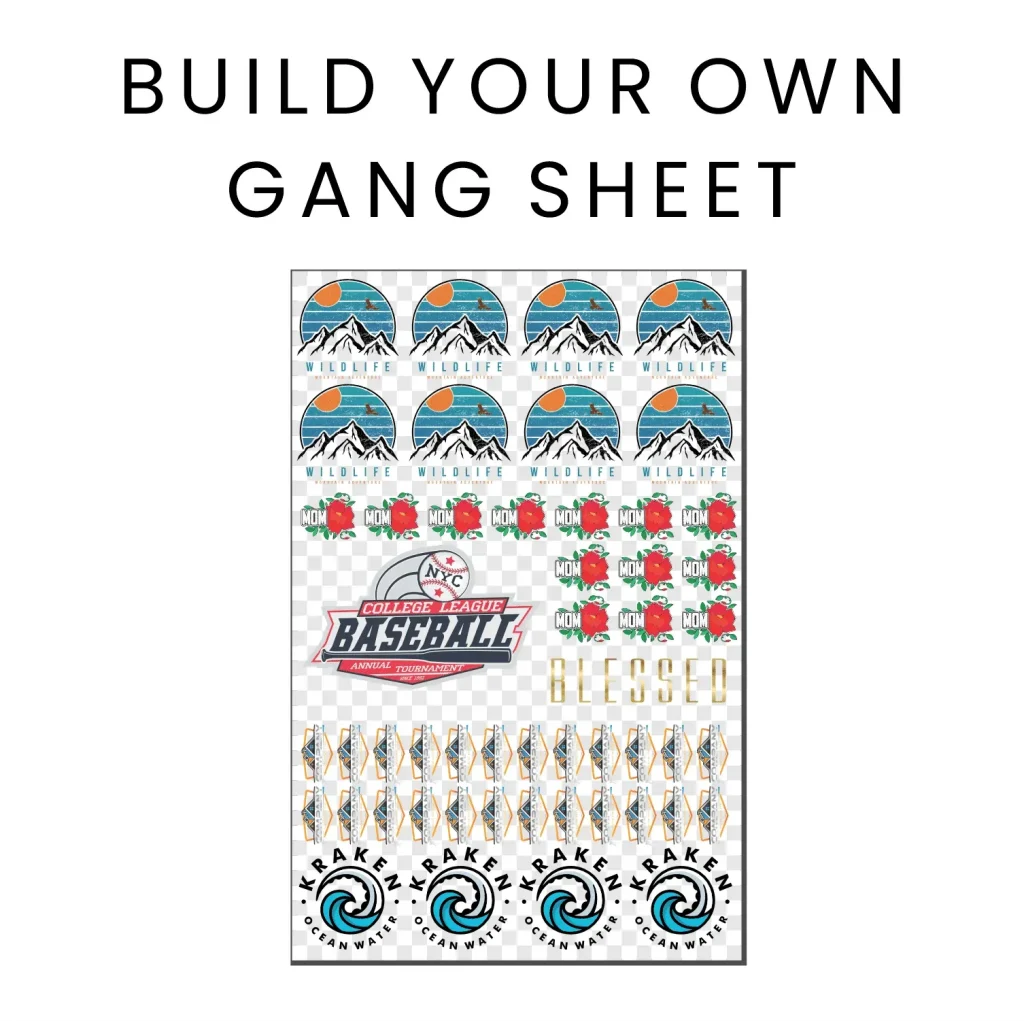

DTF gangsheet builder sits at the core of efficient, scalable textile printing, turning a clutter of ideas into a structured production plan. If you’ve ever wondered how to align multiple designs on a single substrate without wasting time, this introduction offers a practical approach you can apply today. With a focus on batch-ready designs, you’ll pre-plan layouts, manage margins, and predict ink usage to achieve consistent results. A clear DTF printing workflow guides you from layout to export, helping maintain color fidelity and reduce surprises in production. Finally, a gangsheet template generator lets you reuse successful layouts, speeding future runs and keeping your catalog cohesive.

Seen through an alternate frame, the same idea is a layout optimizer that grids multiple images on a single sheet to maximize material use and minimize handling. Think of it as a production planner that translates artwork into ready-to-print files, with clear naming and consistent color rules that printers trust. From an SEO and UX perspective, this approach aligns with concepts like workflow orchestration, asset organization, and scalable batch processing, all designed to turn creative concepts into repeatable merchandise runs.

1) Maximizing Efficiency with a DTF Gangsheet Builder

A DTF gangsheet builder is the backbone of fast, scalable textile printing. By laying out multiple designs on a single substrate, you reduce material waste and accelerate batch cycles, turning concept art into production-ready sheets in a fraction of the time. This approach aligns with a production-focused DTF printing workflow, where planning, alignment, and export readiness converge to keep orders moving smoothly from design to delivery.

In practice, using a gangsheet builder helps you pre-plan layouts, manage margins and bleeds, and standardize color-safe palettes. The result is batch-ready designs that stay consistent across prints, while you maintain tight control over tool paths, substrate widths, and verification steps before sending files to production. The process becomes a repeatable system rather than a one-off task, enabling faster iterations and more reliable output.

2) From Concept to Layout: Planning for Batch-Ready Designs

Successful gangsheet creation starts before you open the builder. Gather assets, confirm print sizes, and decide how many variations you’ll need per sheet. This planning phase supports the notion of batch-ready designs, ensuring you optimize space and minimize ink changes from the outset, which is essential for a smooth DTF printing workflow.

Think of planning as a bridge between artistry and production. Clarify target product sizes, group similar colors to reduce ink shifts, and decide how many design blocks fit on each sheet. With these guidelines in hand, you can exploit a gangsheet template generator later to quickly reproduce proven layouts across new designs with minimal tweaks.

3) Color Strategy for Consistent Gangsheet Outputs

Color management is central to consistent gangsheet results. Organize your artwork into a unified color palette, convert designs to the target color space, and plan how to allocate inks across multiple designs. This disciplined approach supports predictable color fidelity, reduces drift between designs, and aligns with a coherent DTF printing workflow from prepress to press.

A well-designed color strategy also considers practical constraints like ink limits and substrate effects. By grouping designs by color families and predefining palettes within the gangsheet, you can forecast ink usage, minimize color shifts, and maintain uniformity across batch-ready designs, even when combining artworks with varied color complexity.

4) Automating Reuse with a Gangsheet Template Generator

Automation is the multiplier for scale. A gangsheet template generator stores proven layouts and product-size configurations, enabling you to reproduce batch-ready sheets for new campaigns without rebuilding from scratch. This approach accelerates production pipelines and aligns with a broader DTF gangsheet tutorial, where templated layouts become the common starting point for multiple designs.

Templates unlock rapid catalog expansion. Reuse consistent blocks, swap artwork, adjust sizes or colorways, and produce new sheets that retain alignment and margins. As you grow, automated imports, color rules, and pre-designed export presets further reduce manual tweaks, helping you maintain quality while increasing throughput.

5) Export, Proof, and Production Handoff Best Practices

Export decisions shape downstream success. Choose formats that your printer can process with minimal adjustment—PNG with transparency for layers, TIFF for high detail, and PDF for multi-page proofs. Including a print-ready color profile ensures consistency across machines, which is a key element of an efficient DTF gangsheet workflow.

A rigorous proofing routine catches issues early. Produce a test sheet to verify color accuracy and alignment, then review a soft proof on screen and a physical proof on substrate. Clear layer and mask management, plus properly labeled exports, smooths the handoff to production and minimizes rework on batch-ready designs.

6) Common Pitfalls and Pro Tips for Robust DTF Workflows

Common pitfalls include misaligned margins, color drift between designs, and inconsistent file naming. Address these by double-checking grid alignment, enforcing a unified color space, and standardizing naming conventions. These fixes protect batch-ready designs from creeping errors as you scale your gangsheet operations.

Leverage templates, automation, and an organized asset library to sustain throughput. A well-documented workflow, with a practical playbook for steps and color conventions, helps new team members align quickly. Embrace a scalable mindset by using a gangsheet template generator and consistent export practices to keep quality high across all batches.

Frequently Asked Questions

What is a DTF gangsheet builder and why is it essential for batch-ready designs?

A DTF gangsheet builder is a tool that arranges multiple designs on a single sheet to maximize material usage and streamline the DTF printing workflow. It helps plan layouts, set margins and bleeds, define color-safe palettes, and export ready files, turning concept art into batch-ready designs quickly.

How does the DTF gangsheet tutorial help me create batch-ready designs efficiently?

The DTF gangsheet tutorial guides you through planning, grid setup, asset import, color management, alignment, and export steps, enabling a smooth transition from individual designs to batch-ready designs in minutes.

What is a gangsheet template generator and how does it improve scalability for batch-ready designs?

A gangsheet template generator stores proven layouts as reusable templates so you can quickly generate new batch-ready designs for different products and sizes, boosting efficiency in the DTF printing workflow.

Which export formats and color management practices should I use in a DTF printing workflow when using a gangsheet builder?

Export formats typically include PNG (with transparency) for layers, TIFF for high detail, and PDF for proofs. Use a consistent color profile (CMYK), unify color spaces across designs, preserve layer names, and proof on screen and in print to minimize surprises in the DTF printing workflow.

How should I plan designs before opening the DTF gangsheet builder to maximize efficiency?

Before layout, collect artwork, confirm target product sizes and the number of variants per sheet, group colors to minimize ink changes, decide margins and bleed, and define a grid that matches your printer’s capabilities, so you can produce batch-ready designs faster.

What are common pitfalls in the DTF gangsheet builder process and how can I avoid color drift and misalignment?

Common pitfalls include misaligned margins, color drift between designs, inconsistent file naming, and export profile conflicts. Avoid them by standardizing names, using a unified color palette, converting to the target CMYK color space, performing test proofs, and ensuring grid alignment and proper bleed.

| Section | Key Points |

|---|---|

| Introduction | – DTF gangsheet builder is the backbone of efficient, scalable textile printing. – Turns concepts into batch-ready sheets to reduce waste and speed repeat orders. – Improves color consistency across designs and supports a practical, production-focused workflow. |

| Understanding the value of a DTF gangsheet builder | – A gangsheet is a single sheet with multiple designs in a grid, maximizing space and consistency. – Pre-plan layouts, margins/bleeds, color-safe palettes, and export-ready files. – Enables batching and a shift from one-at-a-time work to batch-ready designs. |

| Planning your designs before you open the builder | – Gather assets, confirm print sizes, and decide how many variations per sheet. – Ask: target product sizes and variants per sheet; group colors to minimize ink changes; layered vs isolated graphics; required print area, margins, and bleed. – Treat the gangsheet builder as a planning tool as well as a layout tool. |

| Setting up the gangsheet builder for a batch-ready workflow | – Define grid and dimensions (e.g., 4×6 or 5×7) with margins/bleed. – Import high-res designs (≥300 DPI) in CMYK and normalize color profiles. – Place designs with snap-to-grid and alignment guides; keep edges safe from crop. – Optimize color management by grouping by color families and predefined palettes. – Validate print area and material constraints to match printer capabilities. |

| Creating batch-ready designs | – Generate multiple batch-ready variants from a single layout using templates. – Duplicate and vary artwork, sizes, or colorways; maintain naming conventions. – Build variations for marketing/seasonality while keeping cohesion. – Manage quantities per variant and estimate material usage to reduce waste. |

| Exporting and proofing for a smooth handoff to production | – Export formats: PNG (with transparency), TIFF, and PDF for multi-page or layered proofs; include color profiles as needed. – Preserve layer names and groups for downstream workflow; use flat proofs for quick checks and layered exports for edits. – Proofing steps: print a test sheet for color/alignment/bleed; use soft proofs but verify with a physical proof. |

| Best practices to maximize efficiency and quality | – Standardized naming conventions for designs, sheets, and variants. – Build in waste buffers into quotes and layouts. – Reuse successful templates to speed future runs. – Keep assets organized and document the workflow for consistency. |

| Common pitfalls and how to avoid them | – Misaligned margins: verify grid alignment and consistent margins. – Color drift: use a unified palette and convert art to target color space before layout. – Inconsistent file naming: standardize names and versions. – Export color profile conflicts: align export settings with printer profiles. |

| Advanced tips: templates and automation | – Use a gangsheet template generator to store layouts for common product sizes. – Program automations to import new artwork, apply color rules, and generate batch-ready sheets automatically. – This supports scaling up catalogs and maintains consistency across runs. |

Summary

Conclusion: describes the topic in a descriptive, SEO-friendly way for a DTF gangsheet builder audience.