The benefits of DTF printing are rapidly reshaping the landscape of the textile industry, presenting a modern solution to traditional printing challenges. This innovative method, known as Direct to Film printing, offers a remarkable combination of versatility, efficiency, and environmental sustainability that sets it apart from older textile printing technologies. With its ability to produce vibrant, high-quality prints on various materials, DTF is quickly becoming a preferred choice for businesses looking to thrive in a demanding market. Moreover, as consumers increasingly prioritize eco-friendly practices, the reduced waste associated with DTF printing aligns seamlessly with the growing trend towards sustainable textile printing. As we explore the advantages of DTF printing, it’s clear that this technology is not only a passing trend but a driving force in the future of textile printing.

Also referred to as direct-to-film printing, this cutting-edge technique in textile printing technology is gaining traction for its unique ability to efficiently transfer intricate designs onto fabrics. The emergence of DTF printing is heralded for its advantages, including exceptional print quality and flexibility across a multitude of textiles. As businesses adapt to evolving consumer preferences, the innovation behind direct to film printing could play a crucial role in shaping a more sustainable future in the textile industry. With its low setup costs and minimal waste generation, this method is poised to redefine traditional practices, reinforcing its status as a hallmark of modern customization and efficiency in fabric printing.

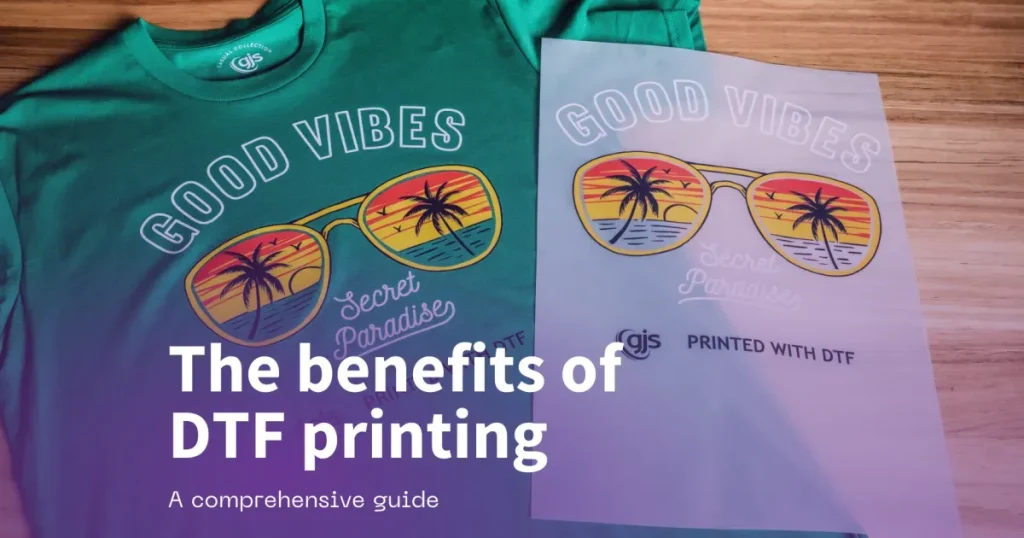

Understanding DTF Printing: The Basics

Direct to Film (DTF) printing is rapidly altering the landscape of textile printing technology. The process involves printing specialized inks onto a film, which are then transferred onto various fabrics using heat and pressure. This innovative approach eliminates the need for complex setups often associated with traditional screen printing, allowing businesses to switch between designs with ease. DTF’s ability to produce high-quality prints on a variety of substrates makes it an ideal solution for those looking to diversify their product offerings.

Additionally, the DTF printing process stands out for its compatibility with numerous materials, ranging from natural fibers like cotton to synthetic varieties such as polyester. This versatility appeals to businesses that cater to niche markets or require custom solutions for their clients. As the textile printing industry evolves, understanding how DTF works lays the foundation for leveraging its numerous advantages.

Benefits of DTF Printing: Why It’s the Future

The benefits of DTF printing go beyond mere convenience; they represent a paradigm shift in how textiles are printed and customized. One major advantage is the exceptional quality of prints produced. DTF technology allows for vibrant colors and intricate detail, making it ideal for custom designs and intricate logos. Companies utilizing DTF can achieve results that rival traditional methods, but with added flexibility and speed.

Moreover, DTF printing reduces setup times, allowing for quick turnaround on orders. In the fast-paced world of fashion and merchandising, the ability to respond rapidly to consumer demands is invaluable. The combination of quality and speed confirms DTF printing as a sustainable and modern solution for businesses aiming to thrive in a competitive market.

Exploring the Versatility of DTF Printing

One of the standout features of DTF printing is its versatility across a wide array of fabric types. This method allows businesses to cater to a diverse customer base by printing on everything from cotton to blends and synthetic fabrics. Unlike traditional screen printing, which often requires different inks and processes for different materials, DTF simplifies the workflow significantly. This flexibility is essential for companies looking to expand their product line without incurring excessive costs.

In practical terms, this versatility means that businesses can take on more varied projects, serving clients with unique needs. Whether producing T-shirts, promotional items, or custom apparel, DTF printing offers the adaptability that’s crucial in today’s ever-changing market. This ability to meet diverse demands positions DTF printing as a leading choice among modern textile producers.

Environmental Impact: DTF Printing and Sustainability

Sustainability is increasingly becoming a priority in the textile industry, and DTF printing is at the forefront of this movement. Traditional printing methods can generate significant waste, both in materials and water usage. In contrast, DTF printing reduces fabric waste by allowing businesses to print only what is necessary for each order. This contributes to a more sustainable production process and aligns with growing consumer demand for eco-friendly practices.

Furthermore, as DTF technology advances, manufacturers are developing formulations that are less harmful to the environment. Innovations in ink technology focus on using water-based inks, which not only reduce chemical usage but also improve the overall health of the production environment. For businesses committed to sustainable textile printing, adopting DTF methods positions them as leaders in responsible manufacturing.

Cost-Effectiveness and Customization in DTF Printing

DTF printing offers a cost-effective solution for businesses, especially when it comes to customization. Traditional printing methods often entail high setup costs and minimal flexibility, making custom jobs prohibitively expensive for smaller companies. In contrast, DTF technology provides an accessible entry point for businesses looking to offer personalized products without a heavy financial burden.

As a result, small businesses and startups are finding DTF printing appealing as it allows them to provide unique designs at competitive prices. This economical approach encourages creativity and innovation, enabling companies to explore a broader range of products while maintaining profitability. For businesses looking to carve out a niche, the cost advantages of DTF printing cannot be underestimated.

Recent Developments in DTF Printing Technology

The landscape of DTF printing technology is evolving rapidly, with significant advancements enabling higher quality and efficiency. Continuous research has led to improvements in ink formulations, which enhance print durability and color vibrancy. These innovations ensure that prints not only look excellent upon delivery but also withstand the test of time, even after repeated washes. Customers increasingly demand longevity in their garments, and DTF technology delivers on this front.

Moreover, equipment enhancements make DTF printing more user-friendly, allowing even those new to the industry to produce high-quality prints. Manufacturers are investing in automation and simplified user interfaces, making DTF accessible to businesses of all sizes. As major companies embrace these technological advancements, it highlights a growing trend that suggests DTF printing is not just an alternative but a revolutionary standard in the future of textile printing.

Frequently Asked Questions

What are the primary benefits of DTF printing compared to traditional methods?

The primary benefits of DTF printing include versatility across various fabrics, vibrant colors, high detail resolution, and significantly lower production costs. Unlike traditional methods, DTF does not require multiple screens, making it quicker for custom orders and small batches. This approach is not only efficient but also eco-friendly, as it reduces waste by allowing precise printing on only the required fabric.

How does DTF printing contribute to sustainable textile printing practices?

DTF printing contributes to sustainable textile printing by minimizing fabric waste through its efficient use of materials. Since only the needed designs are printed, this process aligns with the increasing demand for environmentally friendly practices in the textile industry. The reduction in setup waste compared to traditional screen printing enhances its appeal among eco-conscious brands.

In what ways is DTF printing considered the future of textile printing technology?

DTF printing is viewed as the future of textile printing technology due to its adaptability, speed, and quality. The ongoing advancements in DTF ink technology improve adhesion and durability, allowing designs to withstand multiple washes without fading. Moreover, its ability to produce intricate designs on a wide range of fabrics makes it ideal for meeting modern consumer demands.

What advantages does direct to film printing offer for custom design projects?

Direct to film printing offers significant advantages for custom design projects, including lower setup costs and quicker turnaround times. Unlike traditional methods, which can be costly for small runs, DTF allows businesses to fulfill customized orders economically, making it especially beneficial for startups and small enterprises looking to offer tailored solutions.

Can DTF printing be used on all types of fabrics?

Yes, DTF printing can be applied to a wide variety of fabrics, including cotton, polyester, and blends. This versatility allows businesses to cater to diverse client requests without needing specialized inks for each type of fabric, setting DTF printing apart from many traditional textile printing methods.

What recent developments are enhancing the efficiency of DTF printing technology?

Recent developments in DTF printing technology include advancements in ink formulations that enhance wash fastness and adhesion, as well as improvements in user-friendly printer designs. These enhancements simplify the setup process and make it accessible for businesses of all sizes, increasing efficiency in production and quality of printed designs.

| Benefit | Description |

|---|---|

| Versatility Across Fabrics | Applicable to a wide range of materials, including cotton and polyester, without the need for different inks. |

| Vibrant Colors and Detail | Produces high-quality images with intricate designs and vibrant colors using advanced ink technology. |

| Ease of Production | Significantly faster production speeds compared to traditional screen printing, allowing for quick custom orders. |

| Reduced Waste | Lowers fabric waste by only printing necessary designs, appealing to eco-conscious businesses. |

| Lower Cost for Customization | More economical for small businesses due to lower setup costs compared to traditional methods. |

Summary

The benefits of DTF printing extend far beyond basic printing solutions, revolutionizing the textile industry with its modern techniques. This method is transforming how businesses operate with its remarkable versatility across multiple fabrics, allowing brands to cater to a variety of client preferences. Furthermore, DTF printing produces exceptionally vibrant colors and fine details, ensuring high-quality prints that enhance brand visibility. It significantly speeds up production, making it an ideal choice for fast-paced demands, while also focusing on sustainability by minimizing fabric waste. With lower costs for customization, businesses can offer personalized printing services without breaking the bank. As DTF technology continues to advance, including improved ink formulations and user-friendly equipment, it stands at the forefront of textile printing and ensures that those who embrace it will thrive in an ever-evolving market.