DTF transfers, short for Direct-to-Film transfers, are changing the landscape of the garment printing industry by offering a dynamic and efficient way to create custom printed apparel. This innovative DTF printing technology allows businesses to produce high-quality prints that not only reflect intricate designs but also stand the test of time against fading and wear. As the demand for personalized products continues to soar, the effectiveness of DTF transfers in meeting this need has made them a go-to solution for many in the market. With their ability to print on diverse fabric types, DTF transfers provide unmatched versatility compared to traditional methods. Explore how adopting this cutting-edge technology can propel your business forward in the competitive garment scene, ensuring that you meet the rising expectations of discerning consumers.

The world of Direct-to-Film technology has unveiled fresh possibilities in garment customization, offering solutions that resonate with both entrepreneurs and established brands alike. This advanced printing technique is paving the way for a new era in textile decoration, allowing for vibrant, detailed graphics on a wide array of materials. With an emphasis on personalized products that cater to individual tastes, companies in the garment printing sector can enhance their appeal by adopting DTF printing methods. Moreover, the ability to generate high-quality prints efficiently supports businesses in responding swiftly to market trends and consumer demands. Embracing this innovative approach not only boosts productivity but also ensures that brands remain relevant in a rapidly evolving industry.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology stands out within the garment printing industry as a leading innovation, effectively merging efficiency with quality. This method utilizes a specialized film to transfer designs directly onto various fabrics, creating vibrant and flexible prints that adhere exceptionally well to a multitude of materials. Its unique applicability on untreated fabrics further distinguishes DTF from traditional methods, allowing businesses to expand their product lines without the need for extensive pre-treatment processes.

DTF technology is built on advanced printing systems that maximize color vibrancy and detail. By enabling high-resolution prints, businesses can offer customized designs that cater to individual consumer tastes. The potential for personalized products through DTF is significant, as customers increasingly seek distinct apparel that reflects their personal style or brand identity. This demand is driving the innovation of printing technologies in the garment production sector.

Benefits of DTF Transfers for Businesses

One of the primary benefits of DTF transfers is the unrivaled quality they provide. DTF printing technology ensures that the final products feature high-quality prints that stand out in a competitive market. These prints are not only visually appealing but also designated for endurance, maintaining their integrity through multiple washes. This durability is a crucial factor for customer satisfaction, fostering repeat business as consumers prioritize longevity when choosing custom printed apparel.

Additionally, DTF transfers offer businesses an efficient printing solution. The streamlined process allows for bulk production, enabling companies to meet large order demands swiftly. With the ability to create intricate designs with minimal effort, businesses can expand their offerings to include a variety of personalized products without overwhelming their production capabilities. This efficiency not only saves time but also reduces labor costs, contributing to improved profit margins.

Market Trends Influencing DTF Printing

Currently, the DTF printing market is experiencing a significant surge, with a projected compound annual growth rate (CAGR) between 9-11% in the coming years. This growth signals a shift towards highly customizable garments, largely driven by consumer preferences for uniqueness and personalization. As small to medium-sized enterprises (SMEs) increasingly adopt DTF technology, they can cater to these evolving consumer demands, thus enhancing their market position amidst fierce competition.

Technological advancements continue to make DTF printing more accessible to businesses of all sizes. With lower production costs and improved machinery, new entrepreneurs may enter the custom apparel market with greater ease. This democratization of printing technology means that even startups can offer high-quality DTF prints, meeting consumer needs for personalization effectively. As the garment printing industry adapts to these trends, embracing DTF technology can provide a significant competitive advantage.

Versatile Applications of DTF Transfers

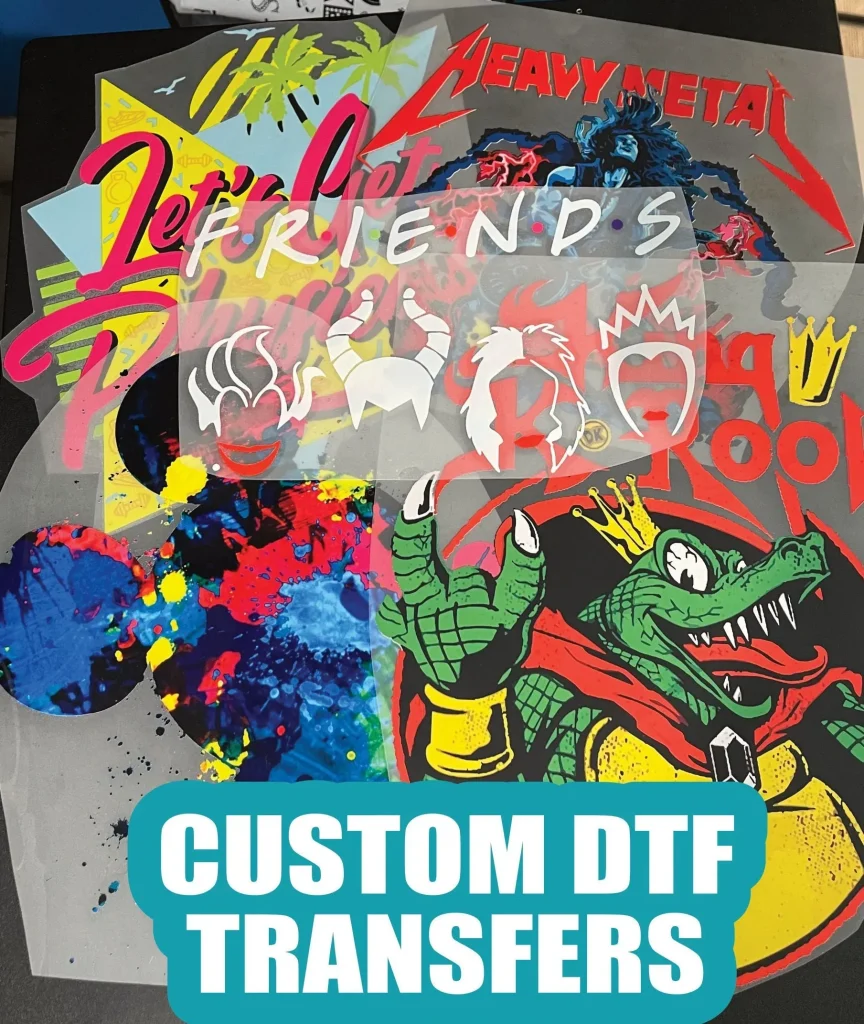

DTF transfers are not limited to just apparel; their versatile nature allows them to be applied to an array of products including bags, hats, and home textiles. This adaptability opens up new market opportunities for businesses, enabling them to diversify their offerings easily. By incorporating DTF printing into various consumer items, businesses can reach different segments and attract a wider audience interested in customized products.

Moreover, the ability to print on various materials broadens the appeal of DTF technology. Whether it’s canvas, polyester, or blended fabrics, DTF ensures that prints remain vivid and durable across multiple surfaces. This flexibility can transform a business’s profit potential by tapping into several different markets, making DTF a powerful tool for innovation in product development within the garment printing ecosystem.

Implementing DTF Technology Successfully

For businesses considering the switch to DTF transfers, successful implementation hinges on several key factors. First and foremost, investing in quality DTF printers and materials is essential to achieving optimum printing results. High-quality inks and films will yield better prints, reduce operational issues, and enhance overall productivity. By prioritizing equipment quality, companies can ensure their custom printed apparel meets high customer expectations.

Furthermore, it is imperative to empower the staff with relevant training. Understanding the intricacies of the DTF printing process, from setup to maintenance, will play a vital role in minimizing errors and enhancing productivity. Additionally, working closely with suppliers for technical support and product sourcing can streamline operational processes, facilitating a smoother transition into the DTF printing realm.

Marketing Your Custom DTF Products

Once DTF printing technology is in place, businesses must adopt strategic marketing to showcase their custom printed products effectively. Utilizing social media platforms to engage with potential customers creates a direct line of communication and helps build brand awareness. Collaborations with influencers or local businesses can enhance visibility and broaden the target market, driving interest in unique DTF offerings.

Moreover, leveraging targeted advertisements can significantly increase traffic to your products. By focusing on the unique selling points of DTF transfers—such as personalization and durable quality— businesses can attract customers who value high-quality, custom apparel. An effective marketing strategy will not only promote unique offerings but also help cement the company’s reputation in the highly competitive garment printing industry.

Frequently Asked Questions

What is DTF Transfers and how does it work?

DTF transfers, or Direct-to-Film transfers, involve printing designs on a special film, which is then applied to garments using heat and pressure. This method produces high-quality prints that are vibrant and detailed, making it a popular choice in the garment printing industry.

What are the advantages of using DTF printing technology?

DTF printing technology offers several advantages, including high-quality prints with vivid colors, durability against fading and cracking, and an easy application process. These benefits make DTF transfers an attractive option for businesses in the custom printed apparel market.

How does DTF Transfers compare to other printing methods?

Unlike DTG (Direct-to-Garment) printing, DTF transfers can adhere to non-treated fabrics, which broadens its application. DTF technology also allows for bulk printing, enhancing efficiency in the garment printing industry, making it a preferred choice for customized products.

What are some practical tips for implementing DTF technology in my business?

To successfully implement DTF technology, invest in high-quality printers and inks, collaborate with reliable suppliers for materials, train your team on the printing process, and embrace effective marketing strategies to showcase your personalized products.

What market trends should I be aware of regarding DTF Transfers?

The DTF transfers market is experiencing growth driven by increasing demand for customization in apparel and advancements in printing technology. This creates opportunities for businesses to innovate and cater to diverse consumer preferences in the custom printed apparel sector.

Can DTF Transfers be used for products other than apparel?

Yes, DTF transfers are versatile and can be applied to a wide range of products beyond apparel, including bags, hats, and home textiles, allowing businesses to diversify their offerings and reach various market segments.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs onto special film, then transferring onto garments using heat and pressure. |

| Advantages of DTF Transfers | Includes high quality and detail, durability, and easy application, making it attractive for businesses. |

| Market Trends and Growth Potential | The market is expected to grow at a CAGR of 9-11% due to demand for customization and technological advancements. |

| Practical Tips for Implementing DTF Technology | Invest in quality equipment, collaborate with suppliers, train your team, and embrace effective marketing strategies. |

Summary

DTF Transfers represent a significant advancement in the garment printing industry, offering businesses the chance to enhance their product offerings dramatically. By leveraging DTF technology, companies can provide high-quality, durable prints that cater to the rising demand for customized apparel. As the market evolves and consumer preferences lean towards personalization, adopting DTF transfers not only helps businesses meet client expectations but also secures a competitive edge in a crowded landscape. Overall, DTF transfers are paving the way for innovation and growth, making them a must for businesses eager to thrive in the dynamic world of textile printing.