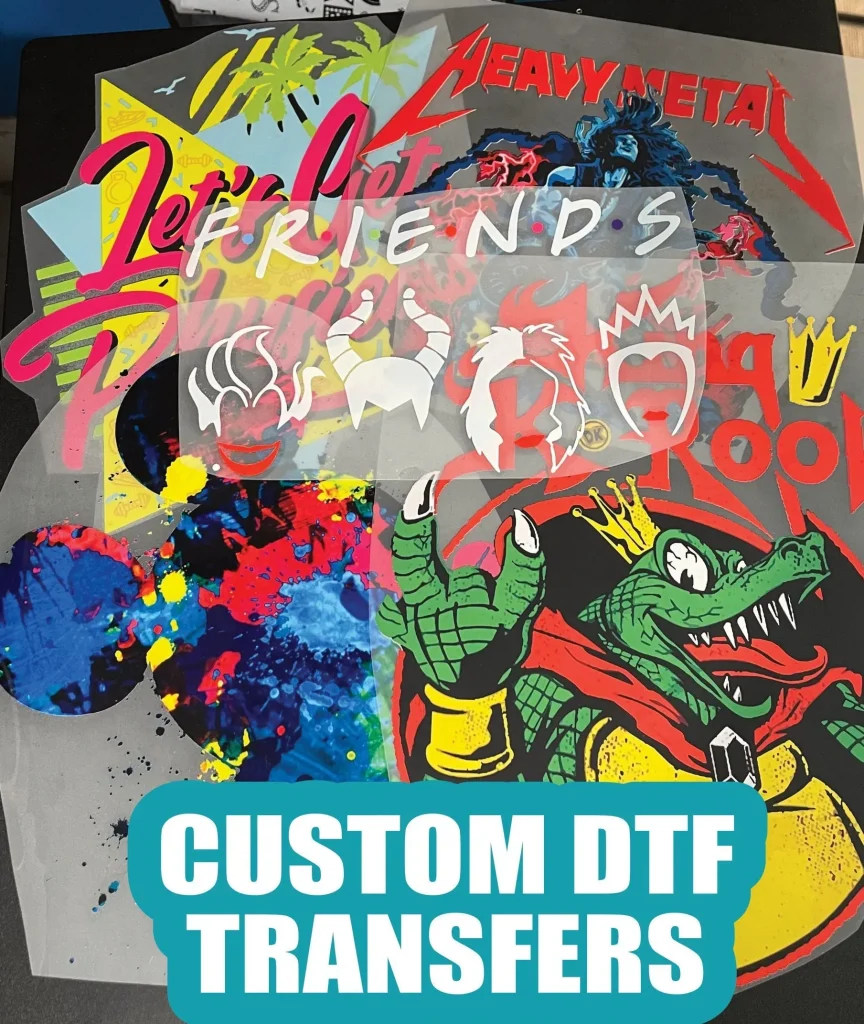

In the realm of custom apparel printing, DTF transfers have rapidly gained recognition as a revolutionary method for creating eye-catching designs on a variety of fabrics. Utilizing Direct-to-Film (DTF) printing techniques, this innovative process allows for the production of vibrant, long-lasting prints that stand out in today’s competitive market. By incorporating elements of sustainable printing practices and leveraging the benefits of DTF transfers, businesses can cater to the growing demand for personalized fashion. This guide will explore key maintenance tips for DTF printers, effective software solutions, and essential trends to help you master the art of DTF printing. As you embark on your journey towards success, understanding these vital aspects will ensure that your custom apparel resonates with quality and creativity.

Direct-to-Film transfers, also known as film-based transfer printing, have emerged as a popular choice among custom printing enthusiasts and businesses alike. This advanced printing method integrates various technologies to produce high-quality, detailed designs that can be seamlessly applied to diverse materials. DTF printing offers a unique opportunity to innovate in the realm of personalized products, positioning businesses at the forefront of the market. Furthermore, the technique emphasizes eco-friendly practices that align with evolving consumer values, highlighting the importance of sustainability in the printing industry. By exploring the various dimensions of film transfer printing, users can unlock new creative possibilities in their custom apparel endeavors.

Understanding the Basics of DTF Printing Techniques

DTF printing, or Direct-to-Film printing, is revolutionizing the world of custom apparel by enabling high-quality graphics to be effortlessly transferred onto fabrics. The process involves printing your designs on a specialized film, which is then applied to the garment using heat and pressure. This precise method allows for exceptional detail and vibrancy in printed fabrics, making it a preferred choice for designers looking to make a statement. Unlike traditional screen printing, DTF caters to intricate designs, multi-color prints, and quick turnaround times, making it more versatile and efficient.

Understanding the fundamentals of DTF printing techniques is crucial for anyone interested in diving into this industry. From selecting the right printer to mastering color profiles, each step plays a significant role in the quality of the final product. Additionally, exploring various DTF printing processes can highlight different applications, such as fashion, promotional items, and even niche markets. Whether you’re a hobbyist or an established business, grasping these principles will ensure that you produce prints that are not only appealing but also durable, enhancing customer satisfaction and repeat business.

Maintenance Tips for Long-Lasting DTF Printers

Proper maintenance of DTF printers is pivotal for achieving consistent, high-quality prints and ensuring the longevity of your equipment. Regular cleaning procedures help prevent ink clogs that could compromise the precision of your prints. This involves checking the nozzles frequently and utilizing appropriate cleaning solutions to maintain optimal functioning. Moreover, scheduling routine maintenance based on your printing frequency helps to mitigate potential issues before they escalate, so your production remains uninterrupted.

Investing in quality inks is another maintenance strategy that plays a crucial role in the printing process. High-quality inks designed specifically for DTF printing can significantly enhance vibrancy and color fidelity in your prints. Additionally, keep track of the internal components and ensure that you are using compatible parts when replacements are necessary. By adhering to these maintenance tips, you can prolong the life of your DTF printers and uphold the high standards expected in the custom apparel market.

Exploring Sustainable Practices in DTF Printing

As the global demand for sustainable practices rises, the DTF printing industry is stepping up to meet consumer expectations. By utilizing eco-friendly inks and recyclable transfer films, businesses can significantly reduce their environmental impact while still producing high-quality prints. Many companies are now opting for inks made with fewer harmful chemicals, which contribute to a safer printing environment and improved health outcomes for users. Engaging in sustainable practices not only helps the planet but can also enhance your brand’s reputation among eco-conscious consumers.

In addition to using sustainable materials, there is a growing emphasis on minimizing waste generated during the printing process. For instance, optimizing print layouts can significantly reduce the amount of transfer film used, easily aligning with sustainable production goals. Brands that adopt these eco-friendly measures often see increased customer loyalty as consumers appreciate businesses that prioritize environmental responsibility. As sustainability continues to shape consumer preferences, incorporating these practices into your DTF printing operations can provide a competitive edge.

Pre-Press Techniques for Perfect DTF Transfers

Pre-press techniques are critical in ensuring that the final DTF transfers come out flawlessly. Ensuring that the transfer film is clean and free from any imperfections before printing is essential to avoid detrimental print quality. Additionally, properly calibrating your DTF printer settings to align with the specific requirements of the material can greatly affect the adherence and vibrancy of the design. Taking these preemptive measures may seem tedious, but they are necessary steps for achieving high standards in printing.

Running test prints is another vital pre-press technique that allows you to fine-tune your settings and make necessary adjustments before committing to the final material. This not only saves resources but also gives you the chance to catch potential errors early. As part of a robust pre-press preparation routine, evaluating color accuracy and resolution in your test prints helps ensure that you deliver the best possible results to your clients, boosting your reputation within the market.

The Role of Software in Enhancing DTF Printing Quality

In the realm of DTF printing, quality software is instrumental in optimizing your design workflow and enhancing print results. Programs like Adobe Illustrator or CorelDRAW offer tailored tools that cater specifically to the needs of DTF printing. These applications allow for design optimization where you can make critical adjustments to ensure that your graphics output meets the necessary technical specifications. Familiarizing yourself with these tools is paramount for achieving print fidelity synonymous with professional-grade apparel.

Additionally, many software solutions provide easy accessibility to various file formats and include user tutorials, which can significantly streamline the design process. By leveraging these resources, users can maximize their productivity without sacrificing quality. Understanding and effectively employing the right software can elevate your DTF printing projects, making it easier to achieve the vibrant designs that your customers desire while maintaining a smooth workflow.

Key Trends Transforming the DTF Printing Landscape

The DTF printing industry is witnessing transformative trends that are reshaping how businesses approach custom apparel printing. The growing popularity of personal branding and custom designs is driving demand, leading to advancements in DTF technology that support higher-volume production with shorter lead times. As companies adopt more efficient practices and advanced printers, custom apparel printing becomes more accessible to a diverse range of businesses, from small shops to large-scale operations.

Moreover, emerging trends in consumer preferences for personalization and sustainability are shaping product offerings. With customers increasingly seeking unique products that reflect their identity, businesses are compelled to innovate continually. This includes integrating eco-friendly materials and exploring novel printing techniques that resonate with contemporary values. Staying ahead of these trends will allow businesses to remain relevant and competitive in the vibrant world of DTF transfers, catering to the evolving demands of the market.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film which is then heat-pressed onto fabric. This method allows for vibrant, high-quality prints that are durable and suitable for various fabric types. DTF printing techniques are particularly popular in custom apparel printing due to their ability to reproduce intricate designs with multiple colors.

What maintenance tips should I follow for my DTF printer?

To maintain your DTF printer effectively, perform regular routine nozzle checks to prevent clogs, establish a cleaning schedule based on usage frequency, and always use high-quality inks specifically designed for DTF printing. Proper maintenance is crucial to ensure consistent print quality and extend your printer’s lifespan.

How can I optimize colors and textures when using DTF printing techniques?

To optimize colors and textures in DTF printing, it’s important to adjust heat settings based on the fabric type you are using. Running test prints can help in calibrating colors accurately. Understanding the interaction between different materials and ink types also enhances the overall quality of your DTF transfers.

What role do sustainable printing practices play in DTF transfers?

Sustainable printing practices are becoming vital in the DTF transfer industry. Using eco-friendly inks and recyclable transfer films not only reduces environmental impact but also appeals to a growing number of conscientious consumers. Implementing greener methods helps businesses stand out in the competitive custom printing market.

Which design software is recommended for DTF transfers?

For DTF transfers, software like Adobe Illustrator or CorelDRAW is highly recommended. These programs offer design optimization features specifically tailored for DTF printing and support a variety of file formats, making them versatile tools for enhancing your printing projects.

What recent developments in the DTF printing market should I be aware of?

The DTF printing market is witnessing significant growth, with an increasing demand for custom apparel and personalized products. New user-friendly DTF printers are emerging, making it easier for businesses, from small startups to large companies, to produce high-quality and vibrant designs on various materials.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A technique that prints designs onto a special transfer film and heat-presses them onto fabrics, producing high-quality, colorful prints. |

| Recent Developments in DTF | The DTF market is growing, leading to a demand for user-friendly printers accessible for businesses of all sizes. |

| Understanding Colors and Textures | Vibrant colors and intricate details can be reproduced; understanding fabric interaction is crucial for print quality. |

| Pre-Press Techniques | Film preparation, printer calibration, and test prints are essential for high-quality DTF transfers. |

| Maintenance Tips for DTF Printers | Routine checks and scheduled cleaning help maintain print quality and extend printer lifespan. |

| Software and Design Tools | Utilizing effective design tools like Adobe Illustrator and software with DTF settings can enhance printing outcomes. |

| Sustainability in DTF Printing | Using eco-friendly inks and recyclable transfer films supports environmental efforts and attracts conscious consumers. |

Summary

DTF transfers are revolutionizing the custom printing industry by offering a versatile and efficient means to produce high-quality designs on various fabrics. With their ability to accurately reproduce vibrant colors and intricate details, DTF transfers stand out in the market. It is essential for businesses to stay informed about the latest trends, embrace effective pre-press and maintenance techniques, and leverage suitable design software to maximize results. Additionally, adopting sustainable practices in DTF printing not only contributes positively to the environment but also aligns with the growing consumer preference for eco-friendly products. By mastering DTF transfers, Print entrepreneurs can set themselves apart in this competitive landscape, ensuring long-term success.