In the world of fabric printing, DTF transfers have rapidly become a favorite among designers and artisans for their ability to produce high-quality, vibrant prints with remarkable detail. This innovative method, short for Direct to Film, allows users to unleash their creativity while ensuring that their designs are brought to life in bold colors and intricate patterns. As we delve into the realm of DTF printing, this article will explore essential tips and techniques for getting the most out of your fabric-based projects, helping you stand out in a competitive market. With the right knowledge and tools on hand, your design creations can truly shine. Whether you’re a seasoned professional or a passionate hobbyist, mastering DTF transfers opens up a world of possibilities in fabric printing.

When creating beautiful designs, the technique of Direct to Film (DTF) is transforming the fabric printing industry. Often referred to as a heat transfer method, DTF printing involves a straightforward process that yields stunning outcomes with vivid colors. This approach allows for a great degree of creativity in design creation, making it an ideal choice for crafting customized apparel and decor items. The versatility of DTF technology makes it suitable for a variety of materials, helping you achieve captivating prints that resonate with audiences. By leveraging the potential of this advanced printing method, artisans can produce eye-catching designs that truly pop.

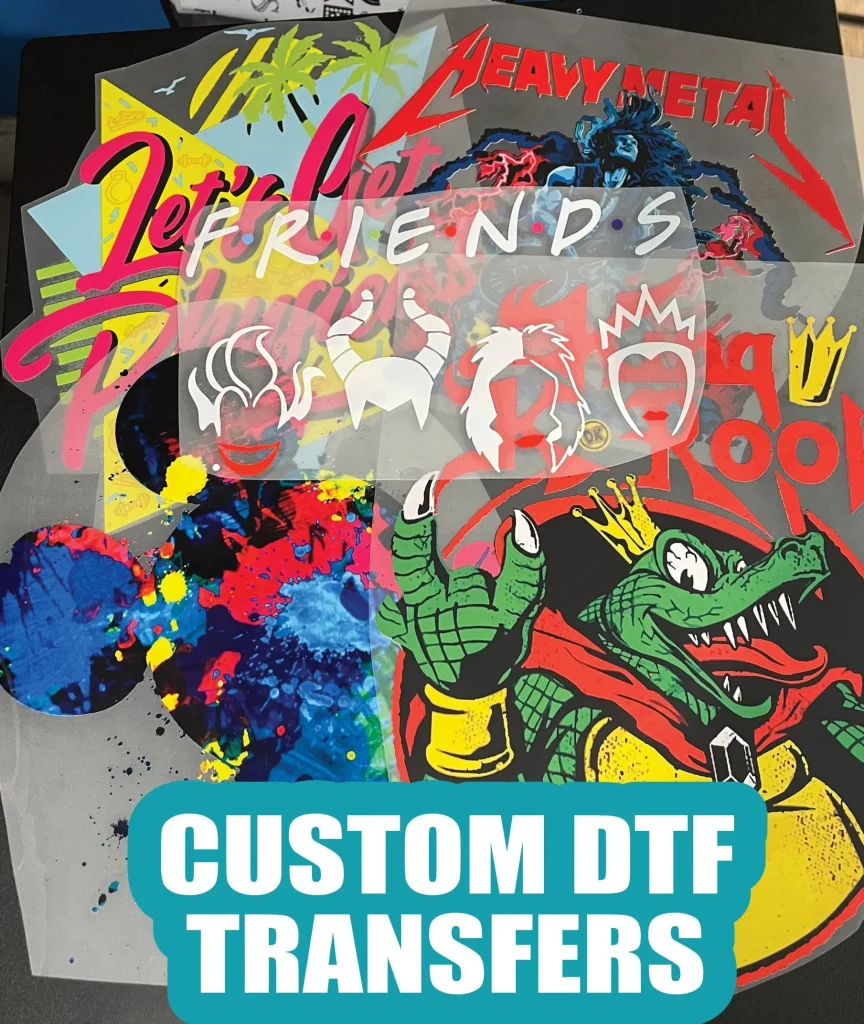

Introduction to DTF Transfers

DTF transfers, or Direct to Film transfers, are revolutionizing the way designers approach fabric printing. By allowing intricate designs and vivid colors to manifest beautifully on a wide range of materials, DTF printing stands out as a versatile and efficient method for both hobbyists and professionals. Its ability to produce high-quality graphics sets it apart from traditional printing methods and has made it a go-to choice for anyone looking to bring their creative visions to life.

As the demand for unique, personalized apparel rises, mastering the art of DTF transfers becomes increasingly important. This innovative method not only enhances the visual appeal of products but also ensures durability, allowing designs to withstand regular wear and tear. For those looking to enter the fabric printing market, understanding DTF technology and its applications is the first step towards creating successful and marketable products.

Getting Started with DTF Printing

Before diving into DTF printing, it’s essential to familiarize yourself with the necessary tools and software. Professional graphic design tools such as Adobe Illustrator or CorelDRAW are highly recommended for crafting high-resolution, detailed designs that translate effectively onto fabric. Additionally, ensuring your design’s file type aligns with your printer’s compatibility is crucial for achieving the best quality output.

A well-prepared design is the foundation of stunning DTF results. Selecting the right color palette can greatly impact how your finished product appears. Testing colors on the actual fabric you plan to use will help you gauge how they translate from screen to material, preventing any unexpected surprises once your design is printed.

Choosing the Right Materials for DTF Printing

The selection of materials is vital when working with DTF transfers. DTF transfers are compatible with a variety of fabrics including cotton, polyester, and blends. This versatility allows for experimentation and gives designers the freedom to choose the best substrate for their projects. However, understanding the properties of each fabric will help you determine which one to use for a specific design, ensuring optimal durability and color vibrancy.

In addition to fabrics, the choice of DTF film also plays a crucial role in the printing process. Different films are designed to perform under various conditions, so it’s important to select a film that complements your chosen fabric and the specifics of your design. Thoroughly researching and testing different types of DTF films will lead to improved results in your fabric printing projects.

Understanding Heat Transfer Techniques

The application of DTF transfers requires careful attention to heat transfer techniques. Properly preheating your fabric ensures that the ink bonds effectively during the transfer process. Adjusting the heat press settings, such as temperature and pressure, is crucial to achieving a flawless transfer that maintains both the integrity of the design and the fabric.

A successful application involves not just the right settings but also a meticulous transfer technique. Positioning your DTF transfer correctly and timing the press duration accurately will prevent issues such as peeling or lifting and contribute to a professional finish. Mastering these techniques is essential for achieving stunning final products that embody your design vision.

Post-Application Care for Longevity

After successfully applying your DTF transfer, proper post-press care is pivotal in maintaining the quality and longevity of your designs. Allowing the fabric to cool completely before removing the film is crucial, as it ensures a strong bond between the ink and the fabric, reducing the chance of damage.

Moreover, adhering to specific care instructions for cleaning and maintaining the fabric will help preserve the vibrancy of your DTF designs. Washing garments inside out on a gentle cycle and avoiding harsh chemicals are small but significant steps in extending the life of your printed creations.

Expert Insights for Outstanding DTF Designs

Leveraging expert insights can significantly enhance your DTF printing experience. Conducting test prints before embarking on larger projects is a common practice among seasoned designers. This approach not only fine-tunes printer settings but also helps in recognizing how different materials react to the transfer process. Experimenting with various substrates can yield insights into achieving the best color and detail.

Additionally, layering colors can be a game-changer for creating complex designs with depth and dimension. Allowing sufficient drying time between layers is essential to avoid unwanted smudges and to ensure a clean separation of colors. Embracing these techniques can elevate your DTF printing, enabling you to create designs that truly stand out.

Frequently Asked Questions

What are DTF transfers and how do they work in fabric printing?

DTF transfers, or Direct to Film transfers, are a printing method in fabric printing where designs are first printed onto a special film and then transferred to fabric using heat and pressure. This technique allows for vivid color designs and intricate details on various materials like cotton and polyester.

What are some essential DTF printing tips for creating high-quality designs?

To create high-quality DTF designs, use professional graphic design software for high-resolution files, carefully select your colors to ensure they appear accurate on fabric, and optimize the sizing and placement of your designs on the material.

How can I choose the right heat transfer settings for DTF transfers?

To select appropriate heat transfer settings for DTF transfers, ensure your heat press is adjusted to the correct temperature and pressure settings specified by your DTF transfer instructions. This ensures effective adhesion without damaging the fabric.

What types of fabrics can I print on using DTF transfers?

DTF transfers are compatible with a wide range of fabrics, including cotton, polyester, and fabric blends. This versatility makes DTF printing suitable for various projects such as t-shirts, bags, and home decor.

How do I properly care for DTF printed designs to ensure longevity?

To care for DTF printed designs, wash them inside out on a gentle cycle, avoid harsh detergents, and air dry when possible. Following these care instructions will help to maintain the quality and vibrancy of your designs for a longer time.

What kind of printer is best for DTF transfers and why?

The best printer for DTF transfers is a high-quality inkjet printer that can effectively handle DTF inks and produce high-resolution prints. Look for printers known for their reliability in fabric printing, as they can greatly affect the outcome of your designs.

| Key Point | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers are popular for high-quality, intricate designs on various fabrics. |

| Advantages of DTF Technology | Versatile, vivid colors, and a simplified design-to-production process. |

| Design Preparation Steps | Select professional software, choose colors carefully, and size the design appropriately. |

| Optimal Print Settings | Use a quality printer, set at least 300 DPI, and select the right DTF film. |

| Application Process | Prepare the substrate, set heat press settings, and apply transfers carefully. |

| Post-Press Care | Cool the design and follow specific care instructions for durability. |

| Expert Tips | Conduct test prints and experiment with layering for best results. |

Summary

DTF transfers are a revolutionary printing method that allows for the creation of stunning designs on various fabric types. With a firm grasp on DTF technology, meticulous design preparation, and a commitment to quality in the application process, you can achieve results that are both vibrant and long-lasting. Adhering to the tips and techniques outlined in this article will ensure that your DTF transfer projects not only meet but exceed expectations. Embrace this innovative printing method to transform your creative visions into tangible artworks that stand out in any marketplace.