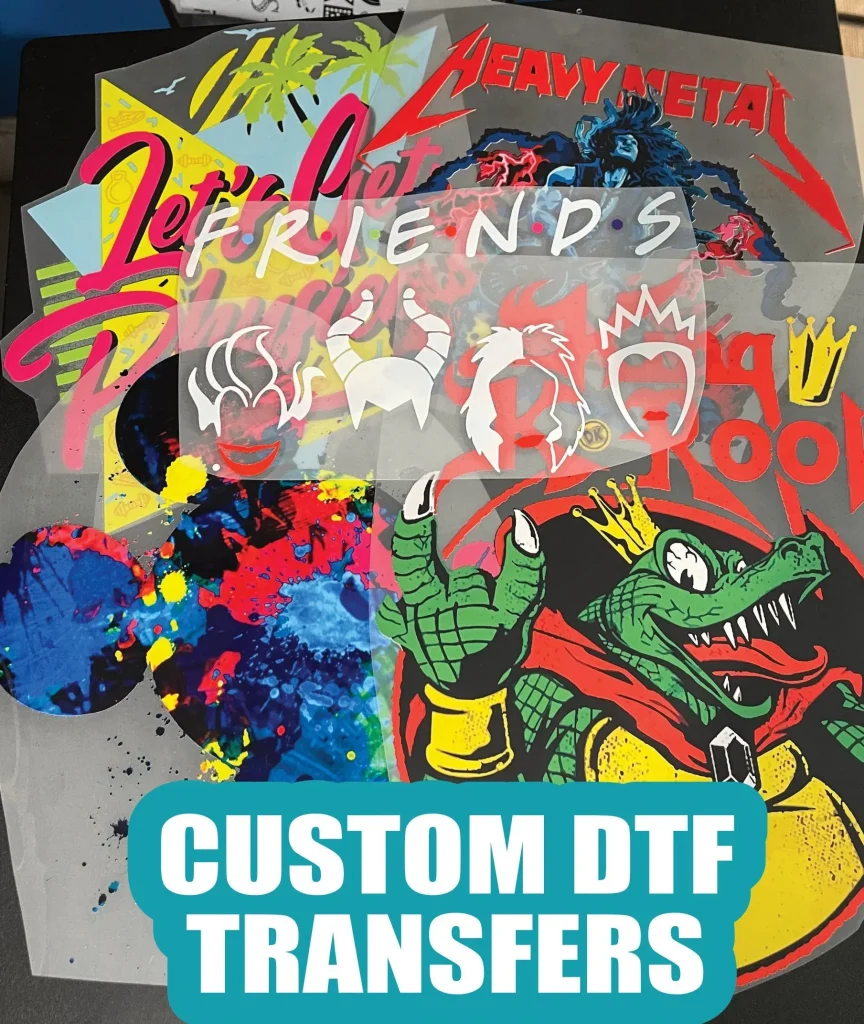

DTF transfers, a revolutionary advancement in custom apparel printing, have surged in popularity due to their ability to create vibrant and high-quality designs with ease. This innovative technique involves Direct to Film printing, where intricate artwork is printed onto a special film, transforming how businesses and hobbyists approach textile customization. To achieve stunning results, having the right DTF printing supplies and tools at your disposal is essential, allowing for efficient and effective transfers. In this guide, we will explore the critical DTF printing process and the must-have equipment that can elevate your printing game. Whether you’re a seasoned professional or just starting, understanding these elements will help you harness the full potential of DTF transfers for your creative projects.

Direct to Film (DTF) printing is transforming the landscape of fabric decoration, offering a versatile solution for those looking to produce eye-catching designs with minimal hassle. This process, often referred to as DTF printing, employs specialized inks and films to ensure a high-quality transfer that adheres easily to various fabrics. The convenience and efficiency of using DTF transfers for custom apparel have made them a top choice among emerging brands and printers alike. As we delve into this topic, we will also highlight the essential DTF printing tools and the supplies needed to master this process. From adhesive powders to heat presses, understanding these components will enhance your ability to create stunning custom designs.

Understanding the DTF Printing Process

The DTF printing process begins with designing your graphics on a computer using specialized software. This design is then printed onto a special transfer film using eco-friendly inks, which are crucial for achieving vibrant and high-definition colors. After printing, the film is coated with adhesive powder that melts and bonds the design to the fabric when heat is applied, ensuring durability and longevity.

This innovative method allows for a broad application range across different fabrics and materials, making it ideal for custom apparel printing. Unlike traditional methods, DTF printing allows for easy handling and application, enabling creators to produce high-quality designs efficiently. Understanding this process is vital for anyone looking to utilize DTF printing for personal or commercial purposes.

Essential DTF Printing Supplies You Need

To successfully create DTF transfers, it is imperative to gather specific DTF printing supplies that will enhance your printing experience. Among these supplies, you’ll require a high-quality DTF printer capable of producing detailed images on transfer film. You’ll also need the right adhesive powder that complements your choice of inks, which is crucial for effective adhesion during the heat transfer process.

Moreover, a reliable heat press is an essential tool in your DTF printing arsenal. The heat press ensures that your designs adhere properly to your chosen fabric, and the right model can significantly impact the finish and quality of your transfers. Lastly, investing in maintenance supplies like cleaning solutions and microfiber cloths will help keep your DTF printer and other tools in optimal working condition for consistent results.

Choosing the Right DTF Transfer Film

Selecting the appropriate transfer film is critical for achieving excellent results in DTF printing. High-quality transfer films are specially designed for compatibility with DTF printers and the inks used, directly impacting the vibrancy and clarity of the final prints. Different films come with various finishes, such as matte or glossy, allowing you to choose the one that best suits your project’s aesthetic.

Using the right film ensures that the design transfers seamlessly and maintains its integrity even after washing. It’s advisable to experiment with different film types to see how they interact with your inks and fabrics, as this can greatly affect the professional appearance of the final product.

Maintaining Your DTF Printing Equipment

Regular maintenance of your DTF printing equipment is crucial to ensuring a long lifespan and consistent performance. Cleaning your DTF printer with appropriate solutions can prevent clogs and enhance the quality of your prints. It’s important to follow the manufacturer’s instructions to avoid damaging sensitive components.

In addition to your printer, keeping your heat press clean is equally important. Dust and adhesive residues can affect the quality of your heat transfers. Routine checks and cleaning will minimize issues, ensuring that your DTF printing projects run smoothly and efficiently.

Trends and Innovations in DTF Printing

The DTF printing industry is continuously evolving with new trends and technologies influencing how custom apparel printing is approached. Innovations in inks and transfer films are enhancing printing capabilities, resulting in higher-quality products that meet the demands of consumers. More businesses are shifting towards DTF printing for its versatility, ease of use, and cost-effectiveness compared to traditional methods.

Staying updated on these trends is essential for anyone involved in DTF printing, from hobbyists to professionals. Engaging with industry forums and attending workshops can provide valuable insights into the latest techniques, ensuring that your skills and knowledge remain current in this fast-paced market.

Starting a Profitable DTF Printing Business

Starting a DTF printing business can be a lucrative venture, especially with the growing demand for custom apparel and personalized items. Initial investments mainly go towards purchasing essential tools such as a DTF printer and heat press, along with high-quality inks and adhesives. While the upfront costs can be significant, the potential for return on investment is quite promising given the popularity of custom designs.

To maximize your success, it’s crucial to identify your niche within the apparel market, whether it be sportswear, promotional items, or custom gifts. Building a strong brand and leveraging social media can also help reach a wider audience and attract customers looking for unique apparel options.

Frequently Asked Questions

What are the essential tools for DTF transfers?

To successfully create DTF transfers, you will need several essential tools: a DTF printer designed for direct to film printing, quality transfer film, adhesive powder to ensure ink adhesion, a reliable heat press for transferring designs, specially formulated DTF inks, and proper cleaning supplies to maintain your equipment. Each of these items is crucial for achieving vibrant and durable prints on fabric.

How does the DTF printing process work?

The DTF printing process involves printing a design onto a special film using eco-friendly water-based inks. After printing, the design is coated with adhesive powder, which helps the ink adhere to fabric when heat is applied using a heat press. This method is favored for its ability to produce high-quality and colorful custom apparel that can be applied to various fabric types.

Why should I choose DTF printing for custom apparel?

Choosing DTF printing for custom apparel is advantageous due to its cost-effectiveness, high-quality results, and flexibility. This method allows for vibrant colors and detailed designs that can be printed on a variety of textiles. Additionally, DTF transfers are easier to produce on small scales compared to traditional methods like screen printing, making it ideal for small businesses and hobbyists.

What types of DTF printing supplies do I need?

Essential DTF printing supplies include a DTF printer, transfer film, adhesive powder, heat press, and specific DTF inks. Auxiliary supplies such as scissors, weeding tools, and Teflon sheets can also enhance the DTF transfer process. Investing in high-quality materials ensures better results in your custom apparel printing endeavors.

What are the benefits of using high-quality transfer film for DTF transfers?

Using high-quality transfer film for DTF transfers is crucial as it directly affects the print quality and durability of the design. High-quality films are designed for compatibility with DTF inks and provide better adhesion when combined with adhesive powder. They also yield brighter colors and clearer images, resulting in more professional-looking custom apparel products.

Can I learn more about DTF printing online?

Absolutely! There are numerous online resources available for learning about DTF printing. Websites, blogs, YouTube tutorials, and online courses provide valuable insights into the DTF printing process, equipment setup, and design techniques. Joining community forums and social media groups dedicated to DTF printing is also an excellent way to connect with experienced printers and share knowledge.

| Key Point | Details |

|---|---|

| What is DTF Printing? | DTF printing uses eco-friendly water-based inks to print designs on a special film, which is then adhered to fabric with heat. |

| Essential Tools | 1. DTF Printer: A specialized printer for DTF applications, like modified Epson printers. 2. Transfer Film: High-quality film designed for DTF printing. 3. Adhesive Powder: Coats the printed film to bond the design to fabric. 4. Heat Press: Industrial-grade press for effective transfer. 5. Inks: Water-based inks specifically for DTF processes. 6. Cleaning Supplies: For regular maintenance of equipment. |

| Other Important Supplies | Accessories such as scissors, Teflon sheets, and weeding tools to improve the DTF printing process. |

| Trends in DTF Printing | Growing popularity in the custom apparel market due to cost-effectiveness and high-quality output. |

| Cost Considerations | Initial investment is required for equipment and materials, but potential returns from customer satisfaction are significant. |

| Learning Resources | Access to online tutorials, blogs, and community forums to enhance skills in DTF printing. |

Summary

DTF transfers are revolutionizing the world of textile printing, providing an accessible and efficient method for obtaining high-quality custom designs. This printing technique leverages eco-friendly water-based inks and specialized transfer films to create vibrant and durable prints on various fabrics. By utilizing necessary tools such as a DTF printer, adhesive powder, and a heat press, any aspiring entrepreneur or hobbyist can successfully dive into the exciting realm of DTF transfers. With innovative advancements and a growing demand for personalized merchandise, now is a perfect time to explore this thriving industry.