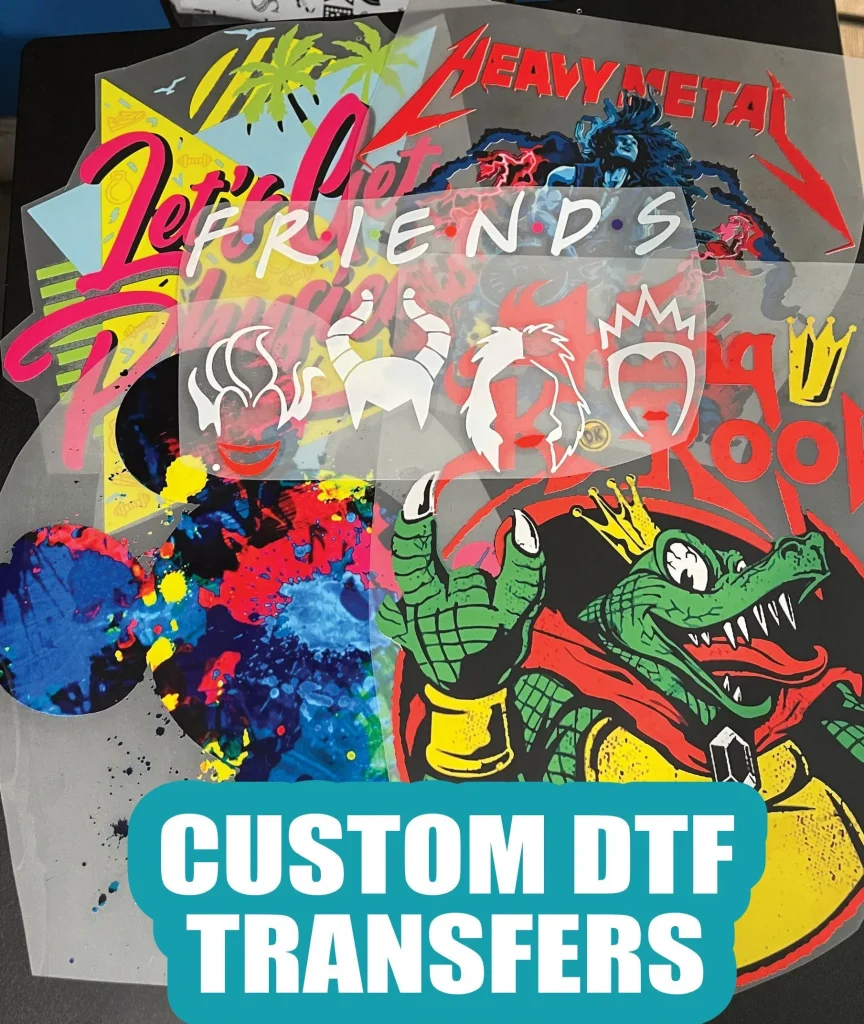

DTF Transfers, or Direct-to-Film transfers, have emerged as an exciting advancement in custom garment printing, transforming the way artists and designers express their creativity. This remarkable technology allows intricate designs to be printed onto a special film, which is then seamlessly transferred onto fabric, yielding vibrant and high-quality results. Unlike traditional printing methods, such as screen printing, DTF transfers provide unparalleled versatility, enabling bold colors and intricate graphics to come to life on various garments. Designers are increasingly embracing DTF transfer technology to push boundaries in creative design, realizing the potential for innovation in custom prints. In this insightful article, we will delve into the world of DTF transfers and uncover how they are revolutionizing the landscape of custom garment printing, empowering creators to easily manifest their unique visions.

Direct-to-Film (DTF) printing represents a significant shift in the realm of textile customization, offering artists a powerful tool for producing eye-catching prints. Also known as film transfer printing, this innovative approach bridges the gap between complex digital designs and tangible clothing items. With the evolution of DTF technology, creators can now access a streamlined process that enhances their design innovation capabilities, enabling them to make unique and personalized garments more efficiently. This method not only elevates the quality of custom garment printing but also opens up new avenues for creative expression among designers, entrepreneurs, and hobbyists alike. As we explore the intricacies of this remarkable printing technique, it becomes clear that DTF transfers are setting a new standard in the world of fashion and design.

Understanding DTF Transfers: The Innovative Technology Behind Custom Printing

DTF transfers, or Direct-to-Film transfers, represent a significant leap in garment printing technology. This method allows for high-quality designs to be printed directly onto a film, which is subsequently applied to fabric using heat. Unlike traditional screen printing, which can be cumbersome and less flexible, DTF transfers provide a seamless approach for creating vibrant and intricate designs. This innovative printing technique has opened up new avenues for custom garment printing, enabling designers to explore the full spectrum of their creative ideas, whether it’s a colorful logo or a detailed graphic.

The process itself is relatively straightforward, allowing for a broader demographic of designers, from professionals to hobbyists, to dive into the world of custom design. With the ability to print high-resolution, multi-color images, DTF transfer technology surpasses many older methodologies. Its versatility makes it not just a tool for artists but a bridge for translation of their imagination into tangible products. As a result, the technology is reshaping the landscape of creative design and elevating the standards of custom garments.

Advantages of DTF Transfers in Creative Design

One of the standout advantages of DTF transfers is their versatility. This technology allows designers to create complex patterns, intricate logos, and vibrant graphics that were previously challenging to reproduce with traditional screen printing methods. Designers can experiment with various styles, textures, and colors, broadening their creative horizons in ways that were once limited. Additionally, DTF transfers are particularly beneficial for small runs, as they keep costs manageable without compromising on quality, making them an ideal choice for startups and independent creators.

Moreover, the accessibility of DTF technology has democratized the world of custom garment printing. With advancements like user-friendly printers, even those with minimal technical background can start their own custom printing business. This marriage of simplicity and high-end design capabilities means that anyone with a creative vision can bring their ideas to life, pushing the boundaries of what can be designed and customized. This not only enhances personal expression but also enriches the marketplace with unique offerings.

The Evolution of DTF Transfer Technology: Recent Developments

Recent developments in DTF transfer technology signal an exciting future for designers and the custom garment industry. Innovative companies are launching products and services aimed specifically at improving the DTF printing experience, such as the recent introduction of platforms that simplify the marketing and ordering process for custom transfers. With tools designed to alleviate the complexities often associated with custom printing, designers can focus more on their creative work rather than logistical concerns.

Additionally, new printer models, such as the LOKLiK iPrinter DTF and AM.CO.ZA’s A3 DTF printer, enhance accessibility and efficiency. These advancements mean that both hobbyists and industry professionals can produce high-quality prints with relative ease, encouraging more individuals to explore the possibilities within DTF design innovation. The industry is rapidly evolving, making DTF technology not just a current trend but a long-term fixture in the customizable fashion landscape.

Getting Started with DTF Transfers: A Beginner’s Guide

Embarking on the journey of DTF transfer design is an inspiring undertaking. To begin, aspiring designers should conduct thorough research on the DTF printing process, understanding the materials and technology involved. Knowledge of various printer models and their features can significantly impact the initial setup. This careful preparation allows designers to select a printer that meets their unique needs and helps pave the way for future success in creating striking garment designs.

Once the technical setup is complete, the real fun begins—getting creative! Utilizing design software such as Adobe Illustrator or CorelDRAW, designers can merge art with technology to create custom graphics that tell their story. This stage is where imagination meets innovation, allowing creators to experiment with colors and textures. After finalizing their designs, it’s important for designers to test the output on DTF film, ensuring that the prints not only meet quality standards but also resonate with their intended audience. Authentic connection with customers often starts with personal, imaginative designs.

Marketing Your DTF Designs: Strategies for Success

Effective marketing of DTF designs is just as critical as the design process itself. As creators step into the realm of custom garment printing, building an online presence becomes essential. This can involve utilizing social media channels, setting up an online shop, and engaging with communities dedicated to fashion and design. Creating visually appealing content that showcases the unique aspects of DTF prints can attract potential customers and collaborators.

Moreover, leveraging targeted advertising and partnerships with influencers can help amplify reach and visibility. Collaborations with fellow designers or local businesses can also nurture a network that supports and promotes one another. By consistently sharing the stories behind their designs and the innovative DTF process, creators can foster a deeper connection with customers, ensuring that their brand resonates on a personal level.

The Future of DTF Transfers: Trends and Predictions

Looking ahead, the future of DTF transfers appears promising as technology continues to advance. Emerging trends suggest a greater integration of automation in the printing process, potentially enhancing efficiency and output quality. Furthermore, as brands increasingly value sustainability, DTF technology may evolve to incorporate eco-friendly inks and materials, aligning with consumer demand for sustainable practices in the garment industry.

As designers continue to embrace DTF printing, we can anticipate a surge in creative innovations and unique design styles emerging from the DTF community. This evolution will not only reshape individual creative practices but also potentially alter the broader consumption patterns in fashion. By setting the stage for these developments, DTF transfers will sustain their position as a transformative tool in the world of custom printing and design.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, utilize a digital printing process where designs are printed onto a specialized film. This film is then applied to fabric using heat, allowing for vibrant colors and intricate designs, unlike traditional garment printing methods.

How do DTF transfers compare to traditional custom garment printing?

DTF transfers offer greater versatility and accessibility compared to traditional custom garment printing methods. They enable designers to create complex graphics with high-quality outputs while often being more cost-effective, especially for small batches.

What are the benefits of using DTF transfer technology for creative design?

Using DTF transfer technology empowers creative designers by providing flexibility in design, exceptional print quality, and durability. This method supports a range of styles, making it easier to produce customized garments that stand out.

How can beginners get started with DTF transfer printing?

Beginners can start with DTF transfer printing by researching DTF processes and selecting the right printer. They should experiment with design software to create unique graphics and test their designs on DTF film before marketing their custom work.

What are the latest developments in DTF transfer technology?

Recent advancements in DTF transfer technology include user-friendly printers like the LOKLiK iPrinter DTF and web-to-print platforms like Snuggle DTF that simplify the printing process, enhancing creative opportunities for both hobbyists and commercial users.

Is DTF printing suitable for businesses looking to offer custom garment printing services?

Yes, DTF printing is highly suitable for businesses aiming to provide custom garment printing services. The technology’s efficiency, quality outputs, and lower entry barriers make it an attractive option for startups and established businesses alike.

| Aspect | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs onto special film for fabric transfer using heat, allowing for intricate and vibrant designs. |

| Advantages of DTF Transfers | 1. Versatility in design allows for complex graphics. 2. Accessibility with user-friendly technology suitable for hobbyists and small businesses. 3. High quality output with vivid, durable prints. 4. Cost-effective for small batch productions. |

| Recent Innovations | Significant advancements include: 1. DTFPrinter’s custom transfer printing. 2. Snuggle DTF’s web-to-print platform. 3. LOKLiK iPrinter DTF for high-quality outputs. 4. A3 DTF Printer by AM.CO.ZA catering to home creators. |

| Getting Started with DTF Transfers | 1. Research DTF printing processes and equipment. 2. Create unique designs using graphic software. 3. Test designs for quality and customization. 4. Market your products through online platforms. |

Summary

DTF Transfers are redefining the landscape of custom garment printing, merging creativity with cutting-edge technology. With their ability to produce intricate designs and vibrant outputs, DTF transfers provide an accessible entry point for both seasoned professionals and budding hobbyists alike. Recent advancements, such as the introduction of user-friendly printers and innovative web-to-print platforms, have made the process even more streamlined, allowing creators to focus on their artistic expression. As this technology continues to evolve, it opens doors to limitless possibilities in personalized design, making DTF transfers an invaluable resource for anyone looking to explore and enhance their creative endeavors.