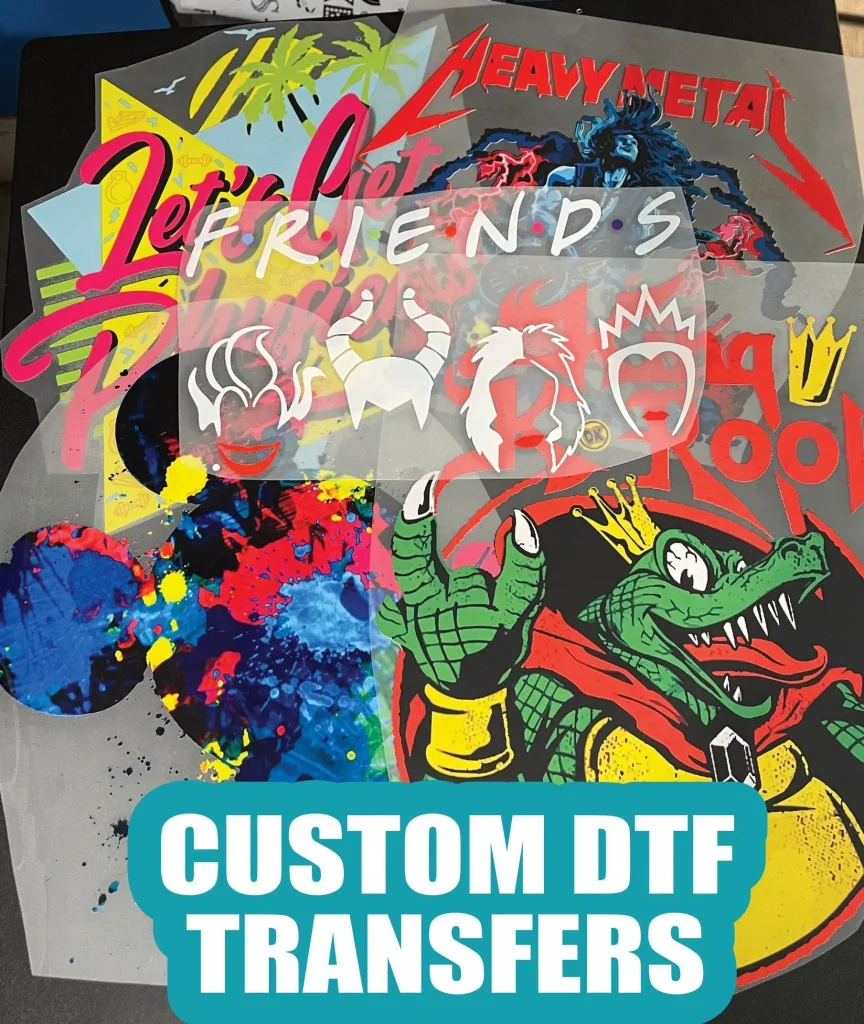

DTF Transfers have emerged as a game-changer in the world of garment printing, offering a seamless blend of vibrant colors and intricate details that captivate customers. Using innovative DTF printing tools, creators can easily transfer their designs onto fabrics while maintaining exceptional wash durability. A key to achieving stunning results lies in selecting the best DTF printer and the right transfer film, which are pivotal for flawless execution. Additionally, incorporating essential accessories like adhesive powder for DTF and a reliable heat press for DTF ensures longevity and quality in the final product. In this article, we will dive into the top five tools you need for successful DTF Transfers, empowering you to elevate your printing game and produce professional-grade designs with confidence.

When it comes to the art of Direct-to-Film printing, having the right equipment is crucial for achieving high-quality artwork that adheres well to textiles. This innovative method, often referred to as film-based printing, utilizes special transfer films along with a compatible printing machine to ensure accurate reproduction of vibrant and durable designs. The process begins with the application of an adhesive powder, which is essential for bonding the printed image to the garment, complemented by the precision of a heat press designed for optimal results. Mastering these tools is vital for any printing enthusiast looking to produce eye-catching and resilient prints on a variety of fabrics without compromising on detail or color vibrancy. In this guide, we will explore the essential resources to enhance your film transfer projects, focusing on the critical items necessary for optimal performance.

Understanding DTF Transfers: The Essential Guide

DTF Transfers, or Direct to Film Transfers, have gained immense popularity in the garment printing industry due to their vibrant color capabilities and detailed designs. This advanced printing process allows for excellent wash durability, making it a favorite among professionals and DIY enthusiasts alike. With its ability to print directly onto a film that can then be transferred to various types of fabric, DTF technology offers a seamless solution for producing high-quality apparel. Understanding the intricacies of DTF transfers is crucial for anyone looking to delve into this exciting area of printing.

In addition to being user-friendly, DTF transfers provide versatility across different types of garments, including cotton, polyester, and blends. This adaptability appeals to a wide range of customers, from small businesses looking to create custom designs to larger enterprises aiming for mass production. The process involves several key components, which, when used together, can ensure that the final product not only looks stunning but is also durable and long-lasting.

Top DTF Printing Tools to Enhance Your Workflow

When embarking on DTF printing, having the right tools is pivotal for successful results. Among the most crucial tools for DTF transfers are the DTF printing tools, which include specialty printers, transfer films, and adhesives. Each component plays a significant role in creating a perfect transfer, guaranteeing that prints come out vibrant, detailed, and wash-resistant. Investing in high-quality DTF printing tools is a step towards ensuring consistency and professionalism in your work.

Additionally, understanding how each tool interacts is essential. For example, the quality of the transfer film affects how well the ink adheres and how vibrant the colors appear after the transfer is completed. Thus, selecting the best DTF printer compatible with your chosen materials is vital for achieving optimal results. As you refine your workflow, these tools will help you work more efficiently, streamline processes, and ultimately enhance the quality of your outputs.

Choosing the Best DTF Printer for Your Needs

Selecting the best DTF printer is a crucial step in ensuring the quality of your transfers. Printers specifically designed for DTF technology, such as those featuring Epson printheads, can significantly improve print performance and color vibrancy. Ideal DTF printers should also accommodate various ink types and provide consistent ink flow to minimize clogging issues, thus enhancing overall print quality. Reviews and recommendations from other users can guide you in making the right choice, as feedback often highlights the strengths and weaknesses of different models.

Moreover, user-friendly features such as easy maintenance and compatibility with various DTF printing tools will save you time and enhance productivity. A good printer should also offer the ability to print on different types of DTF transfer films, thereby increasing your versatility in design options. Ultimately, choosing the right DTF printer tailored to your specific needs can make a significant difference in the quality of your final products.

Exploring DTF Transfer Film Options

The choice of DTF transfer film is a crucial aspect of successful DTF transfers. High-quality transfer films promote better ink adhesion and color vibrancy, which are essential for professional-grade printing. There are various options available in the market, including matte and glossy films. Selecting the right finish depends on the design and the fabric on which it will be applied. Ensuring that the film is compatible with your DTF printer is also vital to avoid any printing mishaps.

Additionally, understanding the characteristics of different transfer films can aid in achieving the desired look. Some films may have superior durability or better performance under certain temperatures and pressures, which can impact the overall success of the transfer. Thus, investing time in researching and testing various types of DTF transfer films can yield significant returns in the quality and vibrancy of your final designs.

The Importance of Adhesive Powder in DTF Printing

Adhesive powder is an integral component in the DTF printing process, ensuring that printed designs adhere properly to the fabric during the transfer. Once the design is printed on the transfer film, the adhesive powder is applied to the wet ink before the heat transfer process is completed. The correct type and amount of adhesive powder can significantly affect the durability of the design as well as the overall appearance, making it a vital area of focus for those involved in DTF transfers.

Moreover, using high-quality adhesive powder specifically formulated for DTF transfers is essential. Different brands offer varying formulations that may better suit certain fabrics or design complexities. Experimenting with different powders can help you discover the best product for your unique needs, ultimately empowering you to achieve outstanding results in your printing projects.

Selecting the Right Heat Press for DTF Applications

A heat press machine is critical for the effective transfer of DTF designs onto garments. The machine applies the necessary heat and pressure to ensure that the ink adheres to the fabric correctly. When selecting a heat press for DTF applications, consider features such as adjustable temperature settings, pressure controls, and a sufficient size to accommodate different fabric types. A reliable heat press can ensure that the transfer process is quick, efficient, and produces high-quality results.

Additionally, adequate heat distribution across the pressing area will ensure uniform results every time. If you are working on larger projects or need to handle various fabrics, investing in a high-quality heat press that supports DTF printing will prove beneficial. The right heat press not only simplifies the transfer process but also enhances the longevity and durability of the printed designs.

Frequently Asked Questions

What are the key benefits of using DTF transfers for garment printing?

DTF transfers offer vibrant colors, intricate details, and excellent wash durability, making them ideal for custom garment printing. The DTF printing process allows for high-quality designs that adhere well to a variety of fabrics, ensuring professional-looking results that last.

How do I choose the best DTF printer for my business needs?

When selecting the best DTF printer, look for models that are compatible with DTF technology, such as those with Epson printheads. Consider printers designed specifically for DTF applications to ensure superior ink flow and vibrant color output, essential for high-quality transfers.

What is the importance of using the right DTF transfer film?

Using the right DTF transfer film is crucial for ensuring proper ink adhesion and quality during the transfer process. A specialized film designed for DTF helps prevent smudging and enhances the durability of the prints, contributing to a professional finish on garments.

How do I properly use adhesive powder for DTF transfers?

To use adhesive powder for DTF transfers, sprinkle it evenly over the wet ink on the transfer film after printing. Heating the film helps melt the adhesive, bonding it with the ink, which is vital for achieving durable and long-lasting designs on fabrics.

What features should I look for in a heat press for DTF applications?

For DTF applications, choose a heat press with adjustable temperature and pressure settings, a user-friendly interface, and a sufficient heating element size to accommodate different garment types. These features ensure that the inks adhere perfectly, producing vibrant and durable prints.

Is it necessary to use specialized software for DTF printing?

Yes, using specialized design software for DTF printing is beneficial. Programs like Adobe Illustrator or CorelDRAW offer robust design capabilities, and software tailored for DTF can enhance your workflow by providing features specifically designed for preparing DTF transfers efficiently.

| Tool | Description | Key Features |

|---|---|---|

| DTF Printer | Specialized printer for DTF transfers, allowing high-quality print on transfer film. | Compatible with DTF technology, Epson printheads, smooth ink flow. |

| Transfer Film | Film specifically designed for DTF processes to ensure ink adhesion and transfer quality. | High-quality, matte or glossy finishes, prevents smudging, compatible with DTF printers. |

| Adhesive Powder | Ensures printed designs adhere effectively to garments during the heat transfer process. | Quality formulations for DTF, proper amount distribution affects appearance. |

| Heat Press Machine | Applies heat and pressure to transfer printed design from film to fabric. | Adjustable temperature and pressure settings, user-friendly, suitable for various sizes. |

| Software | Essential for creating and preparing designs for DTF printing. | Programs like Adobe Illustrator and CorelDRAW enhance workflow and design capabilities. |

Summary

DTF Transfers are an innovative method for applying designs to garments, greatly enhancing the customization of apparel. The success of DTF printing relies heavily on the right tools, including a specialized DTF printer, quality transfer film, effective adhesive powder, a reliable heat press machine, and versatile design software. Each tool plays an essential role in ensuring that the final prints are vibrant, durable, and visually appealing. By investing in these components, print makers can significantly improve their DTF transfer process, yielding high-quality products that meet both aesthetic and durability standards. As DTF printing continues to evolve, staying informed about the latest tools and techniques will further enhance the capabilities of businesses in the garment printing industry.